A kind of electrical fast connection structure of LED lamp tube

A technology of LED lamp tube and quick connection, which is applied in the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of high assembly cost, low reliability, and complicated assembly, and achieve simple assembly and structure The effect of novelty and changeable power supply mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

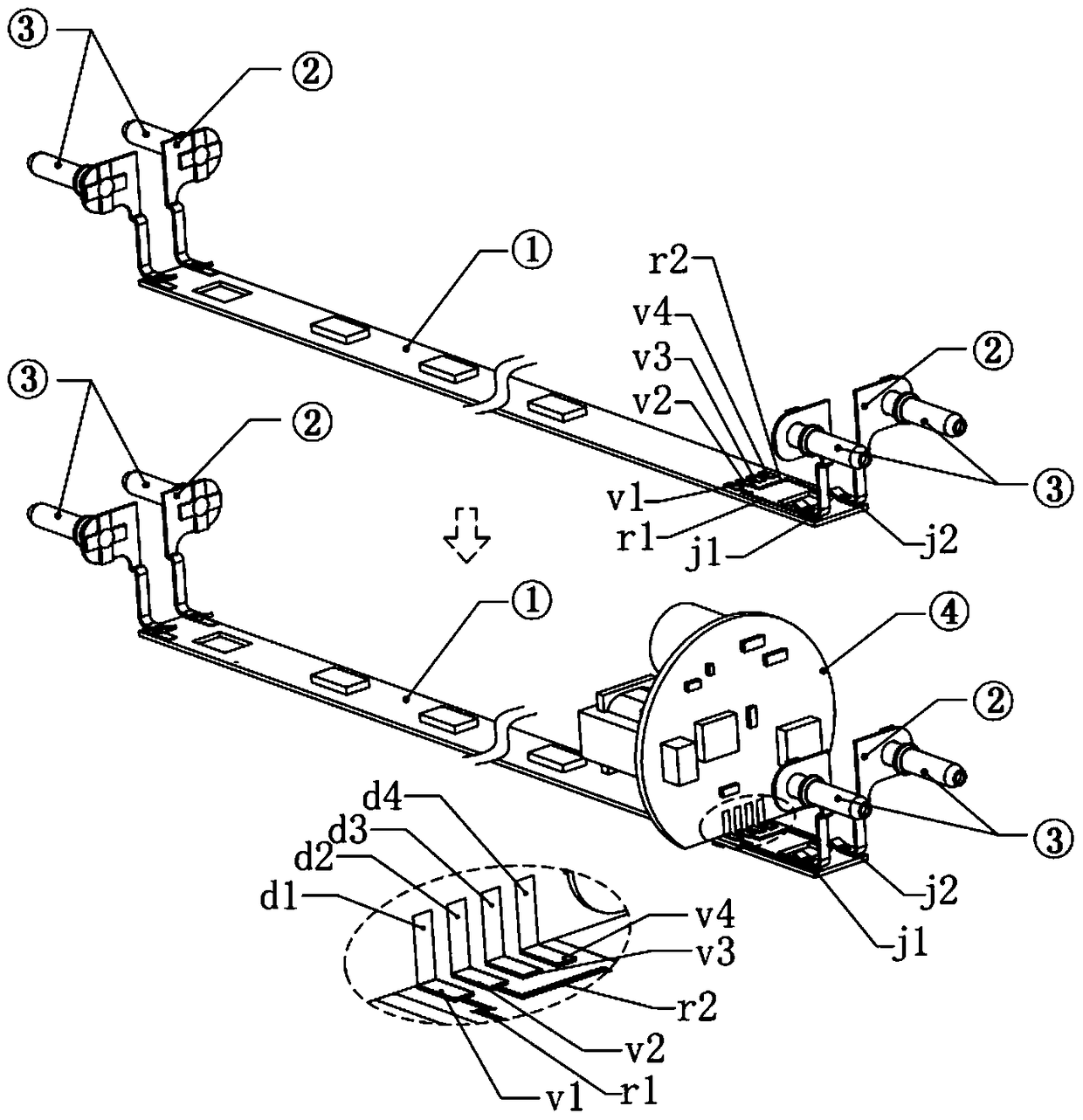

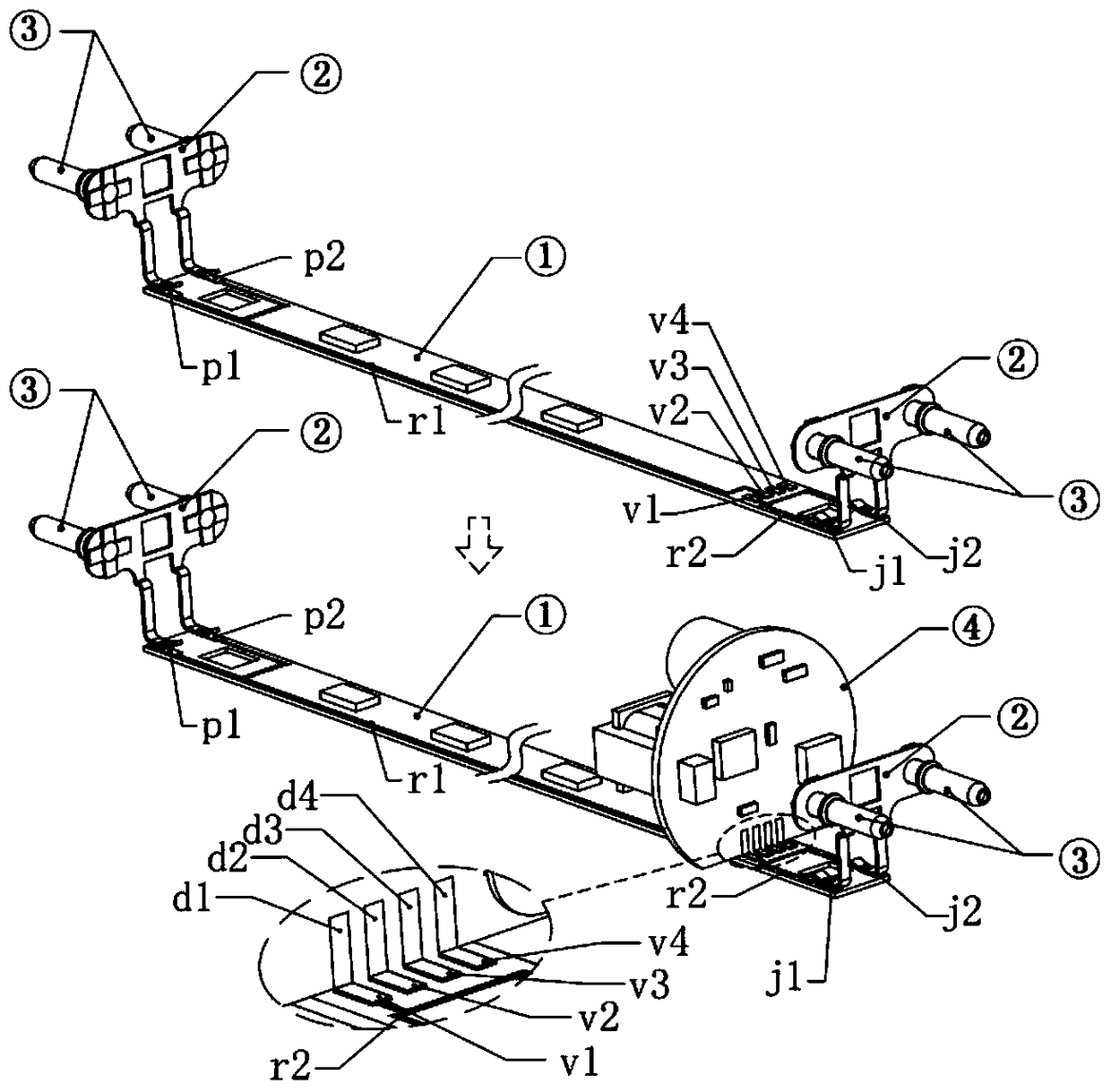

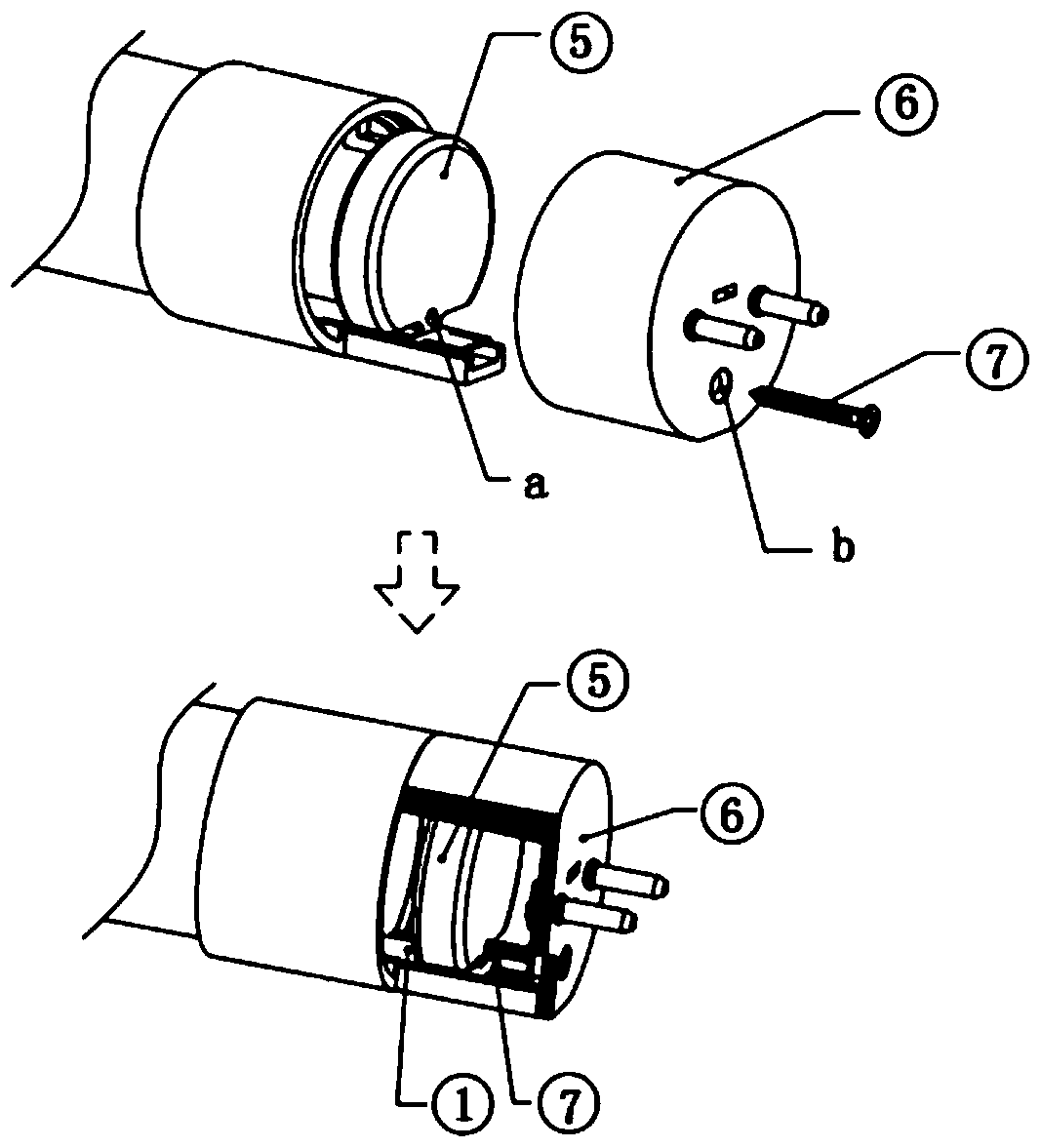

[0017] The electrical quick connection structure of the LED light tube includes the LED light source assembly. The LED light source assembly is composed of a display board and LED lamp beads. There are two contacts at the left and right ends of the display board. Connection, two pins are connected to the outer side of each conductive shrapnel, there are a number of pads on the side of the display board near the end, and a number of pads corresponding to it at the bottom of the power board. Several pads are mated for connection. There are two contacts p1 and p2 at one end of the display board, two contacts j1 and j2 at the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com