Microscope focusing device based on ultrasonic motor drive

A technology of ultrasonic motors and focusers, applied in microscopes, instruments, optics, etc., can solve the problems of difficult to control and adjust the amplitude, difficult to find the focal length, complex structure, etc., so as to save the locking device and simple structure , Improve the effect of focusing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

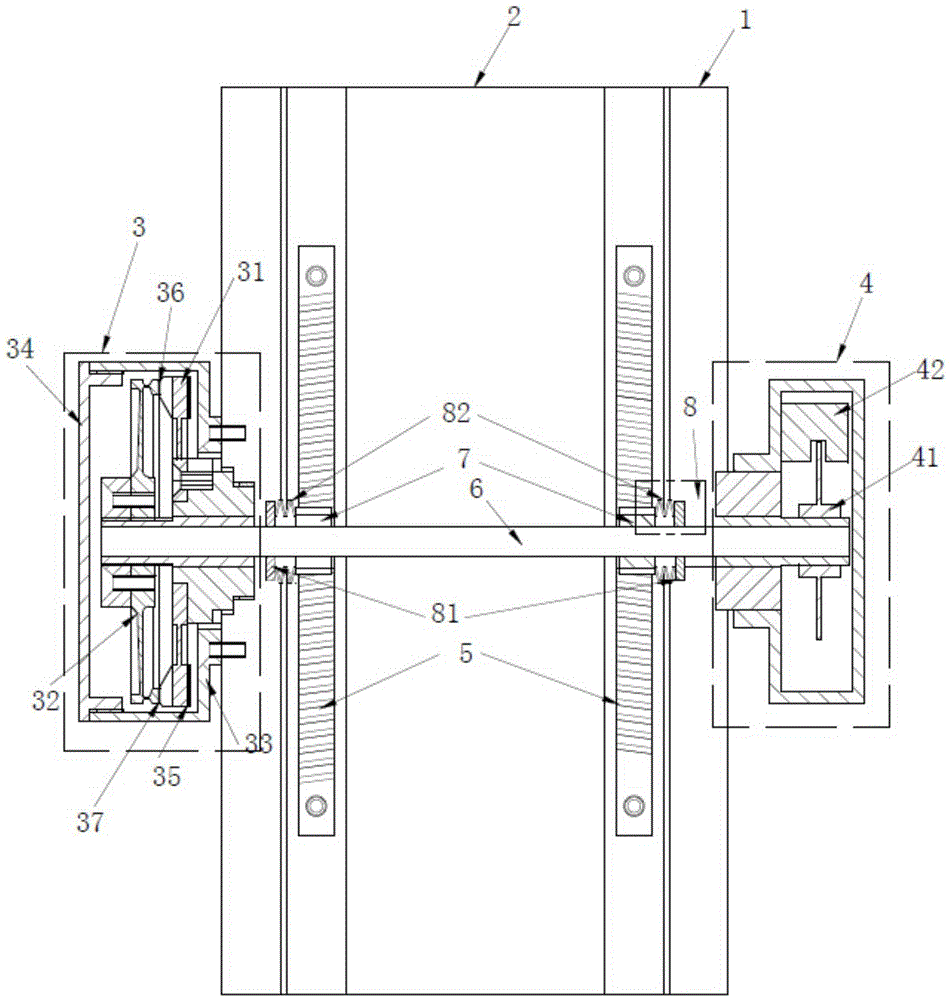

[0010] like figure 1 As shown, a microscope focuser driven by an ultrasonic motor includes a fixed base 1 , a supporting plate 2 , an ultrasonic motor 3 , and an encoder 4 . A ball guide rail is arranged between the supporting plate 2 and the fixed seat 1, and two gear racks 5 are arranged parallelly along the moving direction of the supporting plate on the supporting plate 2, and the gear racks 5 have a horizontal slope. The ultrasonic motor 3 and the encoder 4 are arranged on both sides of the fixed seat 1 respectively, the mandrel 6 of the ultrasonic motor 3 is positioned above the supporting plate 2 and perpendicular to the rack 5, and the encoder 4 is fixed on the side of the ultrasonic motor 3. 6 ends of the mandrel. Two pinion gears 7 are also fixed on the mandrel 6, and the pinion gear 7 also has a horizontal slope, and each pinion gear is meshed with a pinio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com