Patents

Literature

37results about How to "Avoid mechanical errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

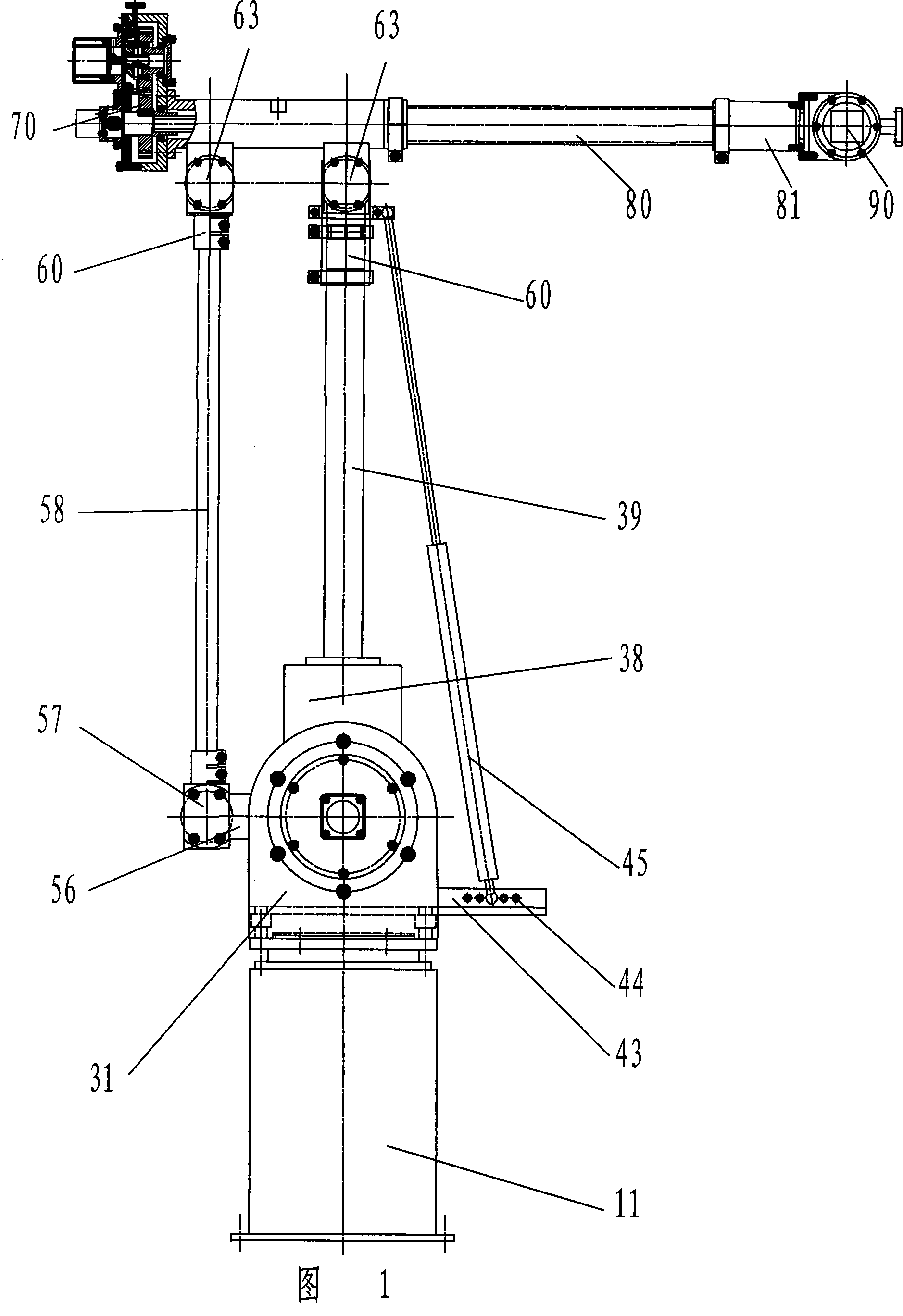

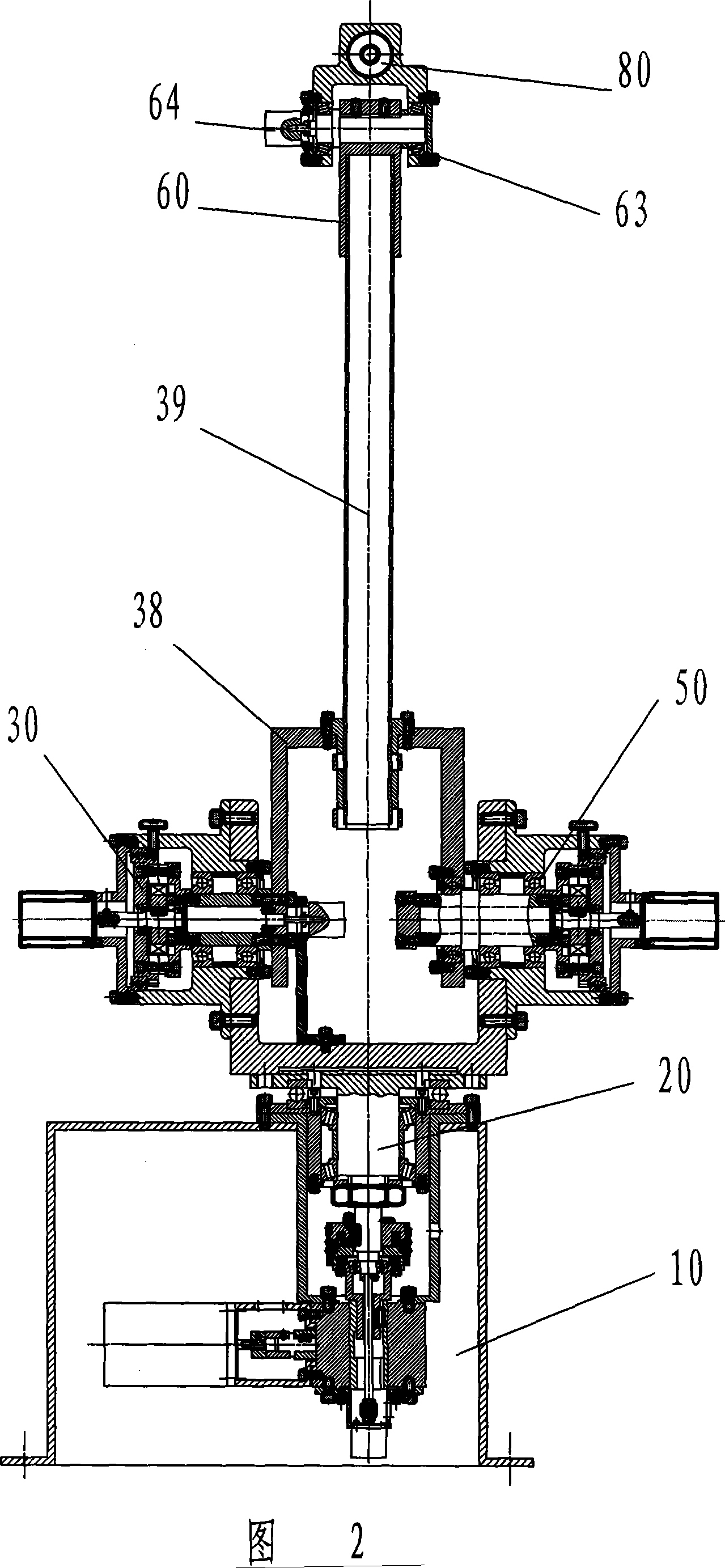

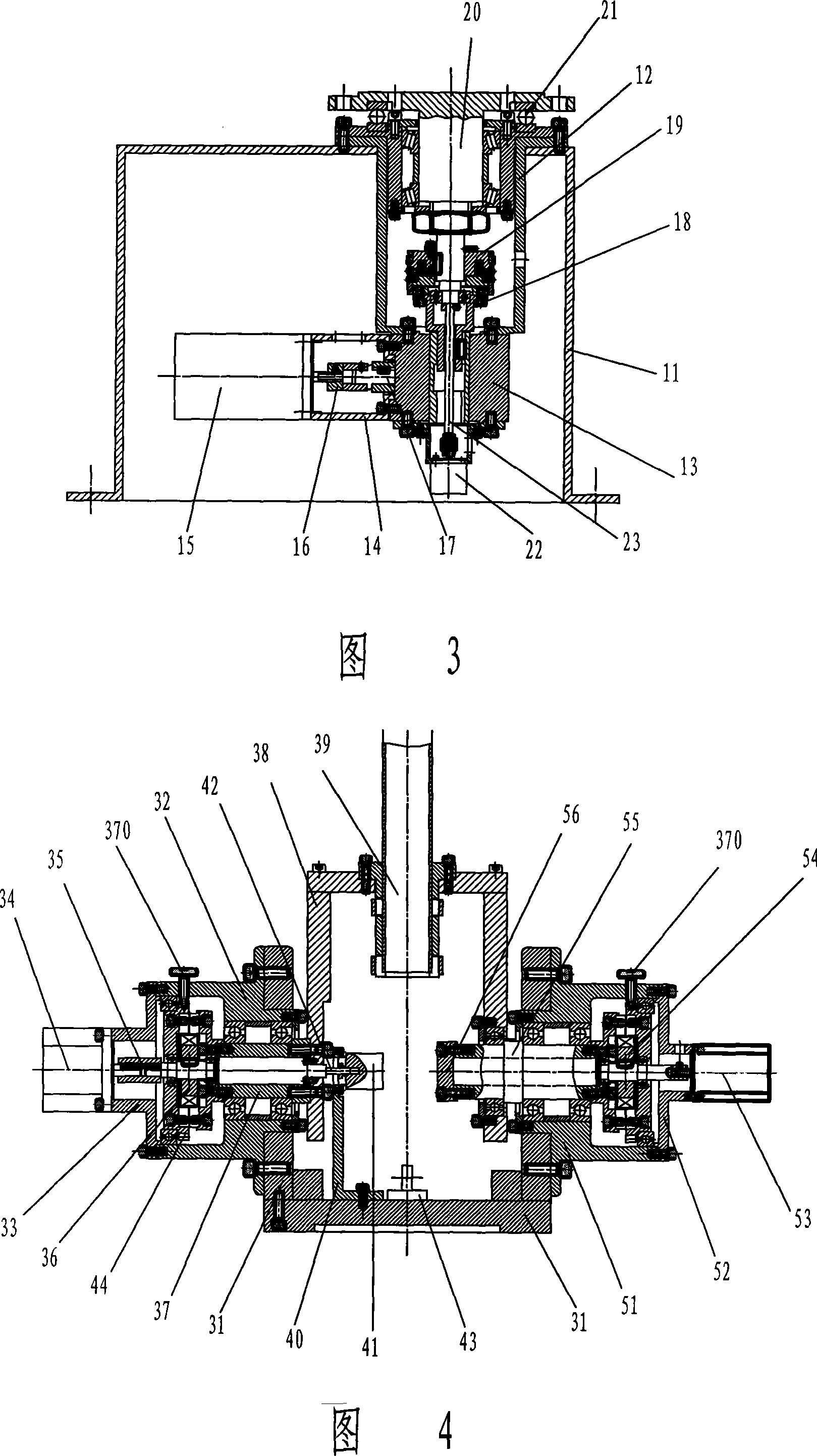

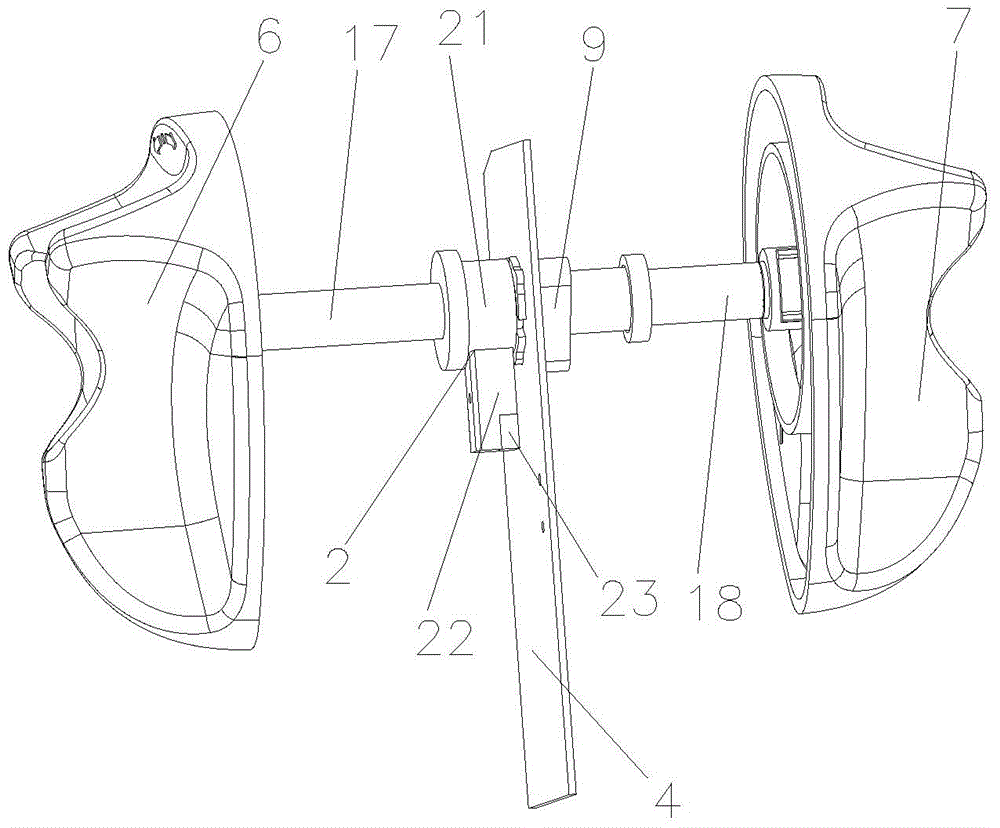

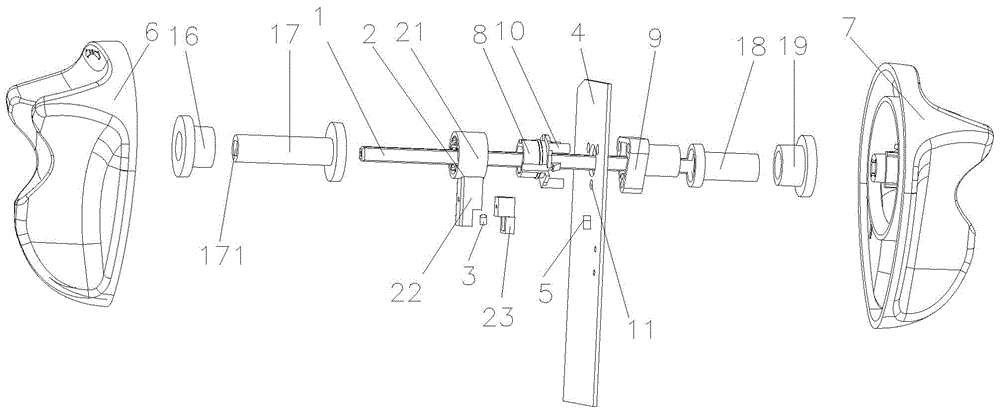

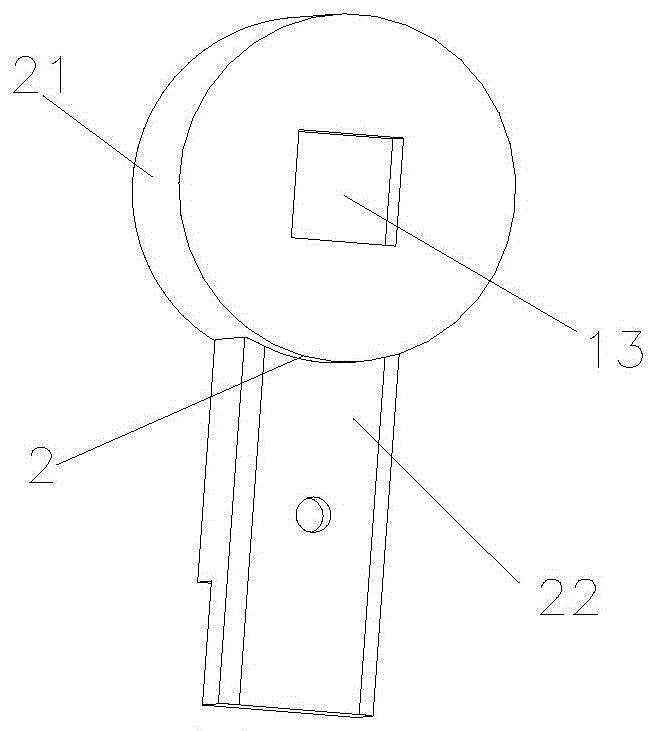

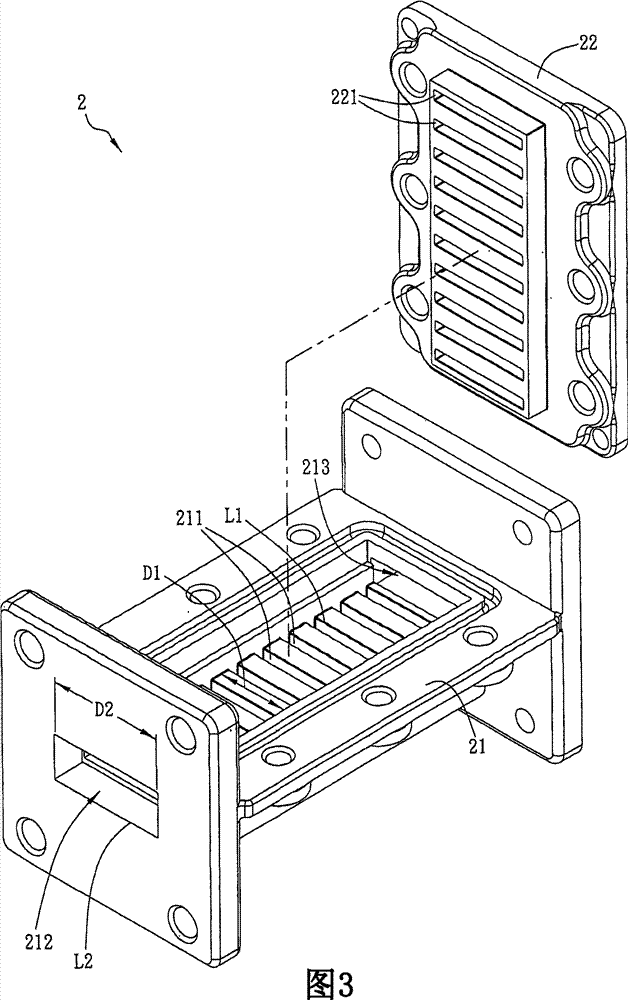

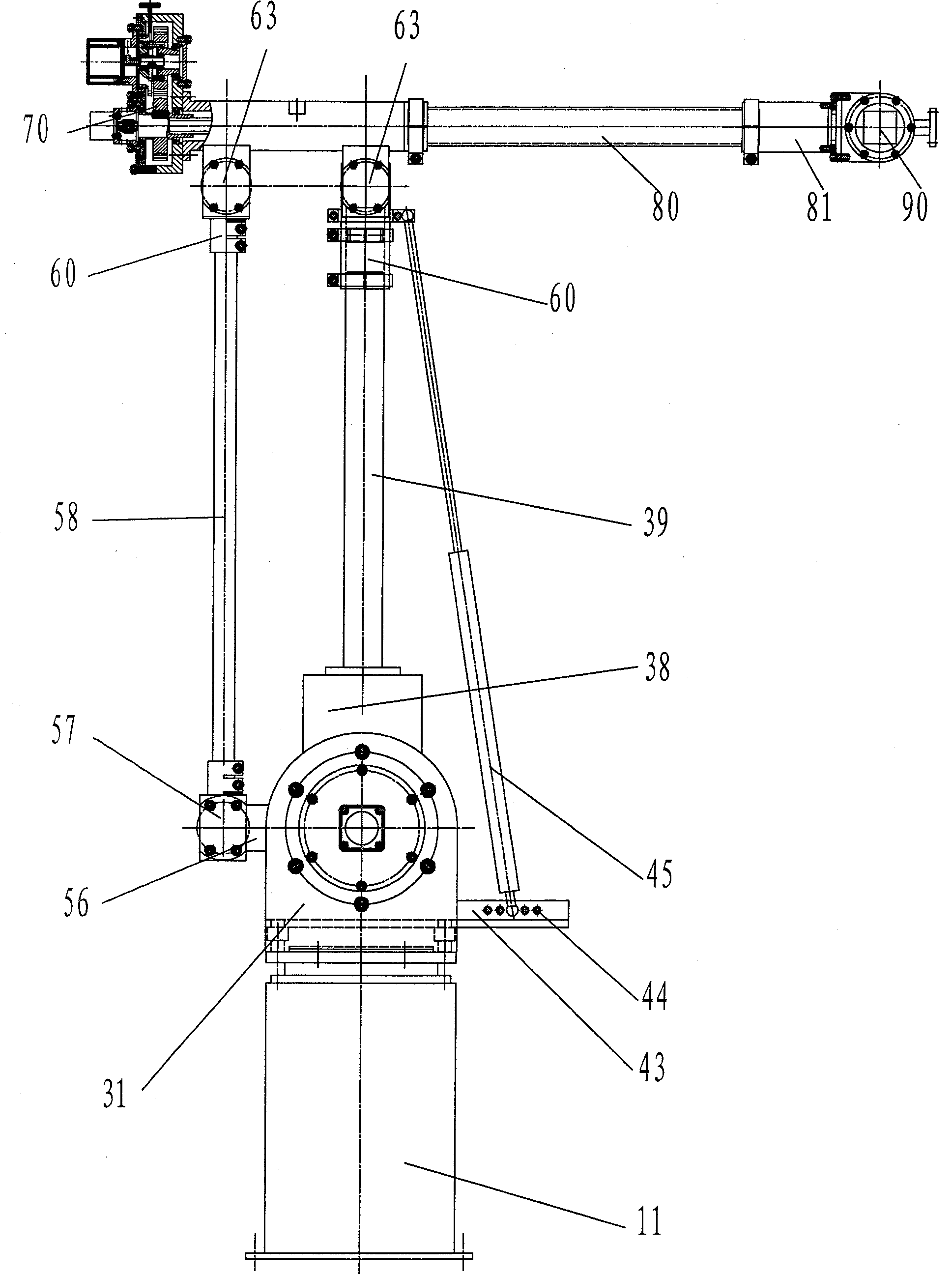

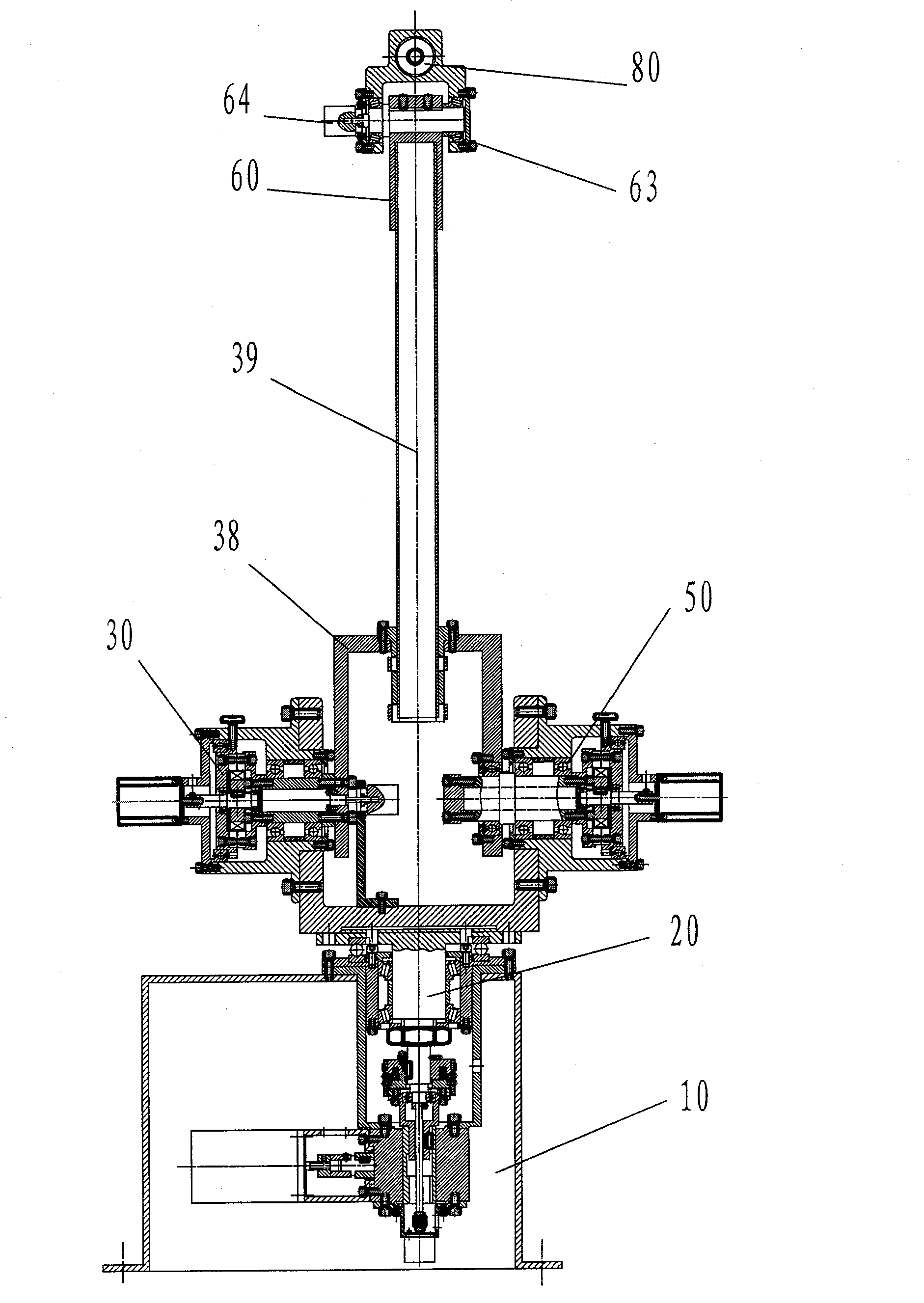

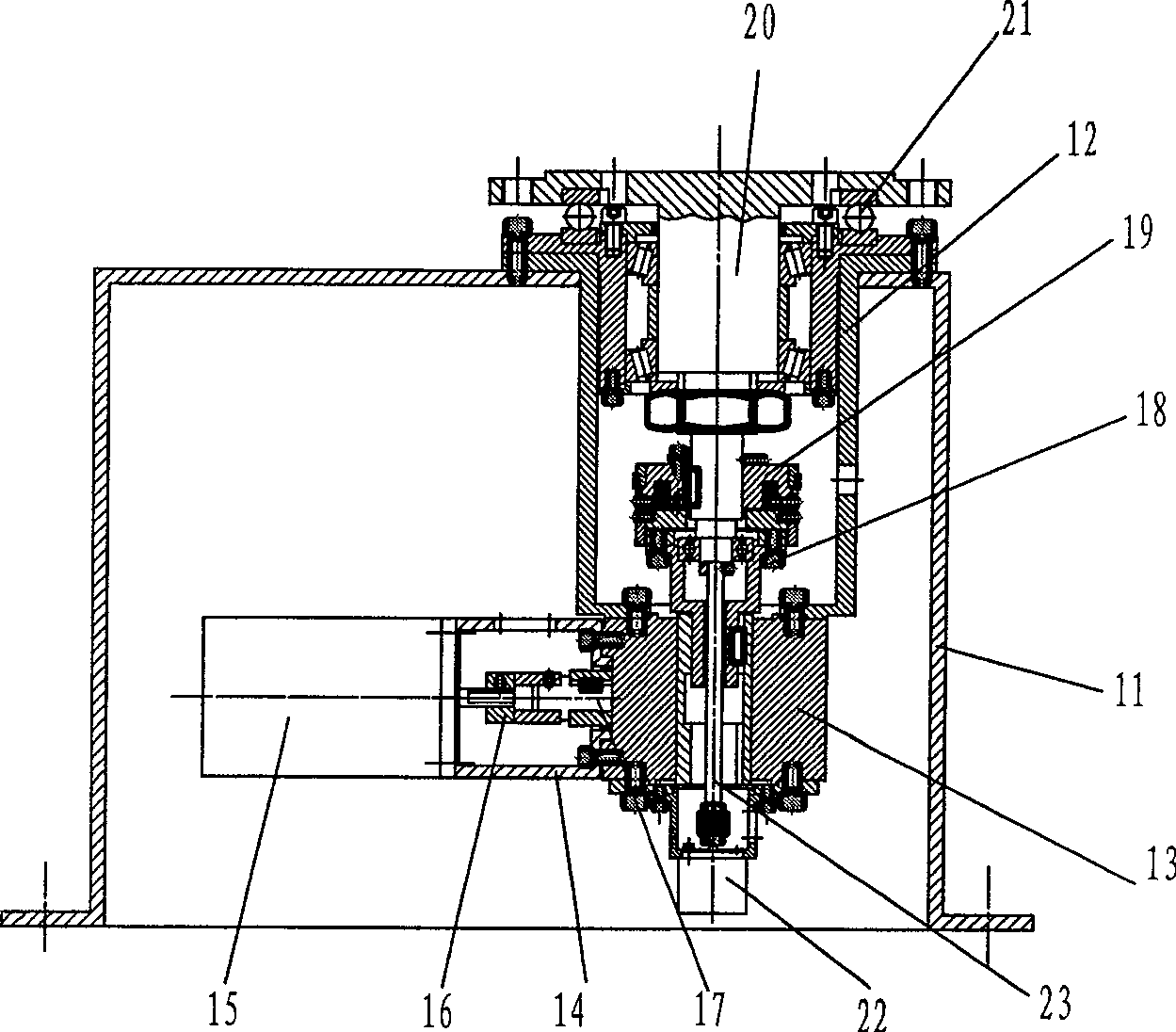

Active-passive joint-arm type measuring robot

InactiveCN101024286ACompensation accuracyMake up for the deficiency of only passive data collectionMeasurement devicesManipulatorGeometric relationsMeasuring output

The invention relates to active passive knuckle arm type measuring robot. It includes I, II, III, IV, and V shaft assemblies. Its features are that each shaft assembly is set actuator and active passive switching unit; encoder used to measure output corner is connected with the output axis. The invention has high measuring accuracy, can actively process trace plan. The encoder can collect final moving corner for each knuckle axis to avoid mechanical error between step motor and harmonic reducer. The invention can be widely used in various products measuring and detecting.

Owner:廊坊智通机器人系统有限公司

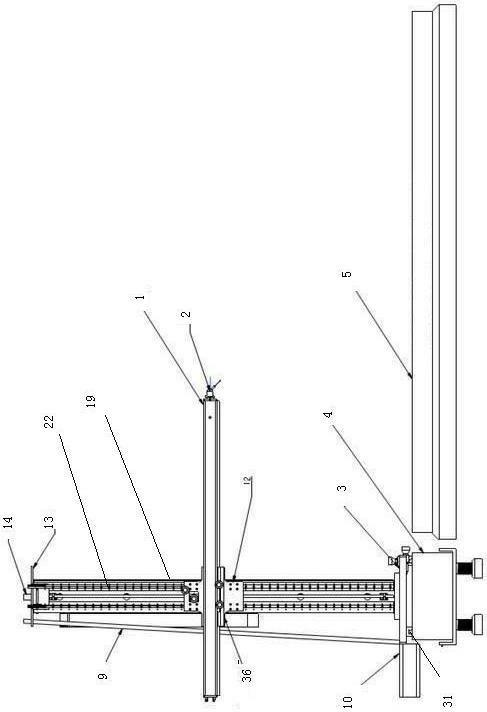

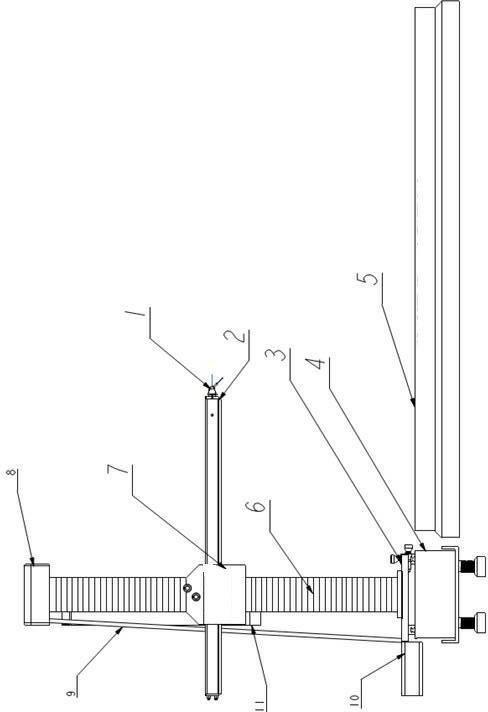

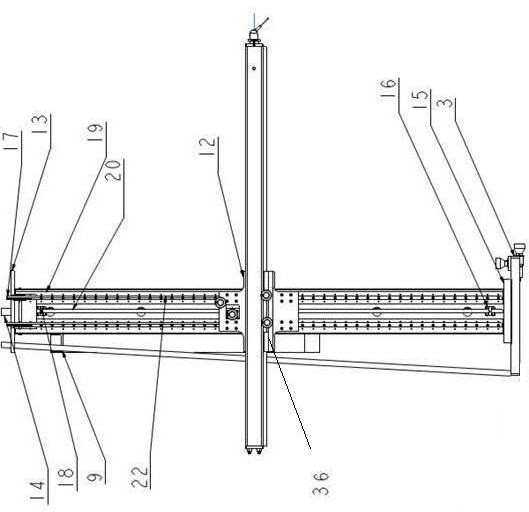

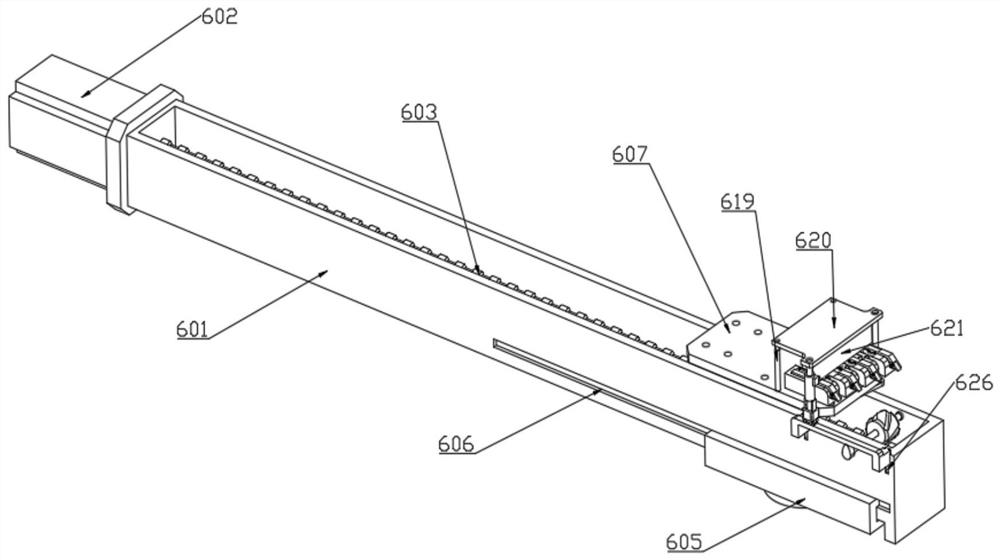

Horizontal arm type three-coordinate measuring and ruling machine

InactiveCN102679929ALower acquisition costsGuarantee stabilityMeasurement devicesOther workshop equipmentThree-dimensional spaceCoordinate-measuring machine

The invention discloses a horizontal arm type three-coordinate measuring and ruling machine, which includes a base, an upright column and a horizontal arm, wherein the upright column and the horizontal arm are made of lighter material, namely aluminum; all three shafts adopt two sets of linear slides; and the linear slide of the horizontal arm is mounted by adopting two mutually vertical surfaces, and an adjustable pull rod is mounted in the horizontal arm for adjusting the curve and deformation caused by other causes as self weight. The horizontal arm type three-coordinate measuring and ruling machine solves the problems in the market that the existing three-coordinate ruling machine has unstable mechanism, complex structure and high cost, and is complex to machine the parts and inflexible to operate. The shafts are mutually vertical and matched with the precise linear slides to realize the three-dimensional movement, so as to achieve the measuring and ruling functions in the three-dimensional space; and the three-coordinate measuring and ruling machine can support all sorts of triggering, analog scanning and non-contact optical measuring heads, and can be widely applied to the measuring and ruling of large mechanical parts as automobiles, motorcycles, excavators, ship engines and dies.

Owner:SHANDONG JINMA UNIONTECH METROLOGICAL TECH

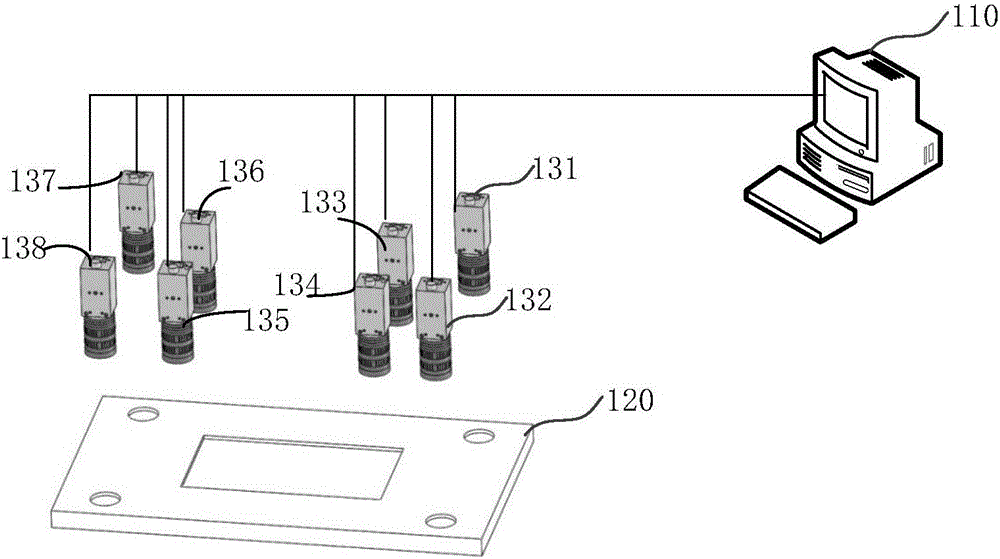

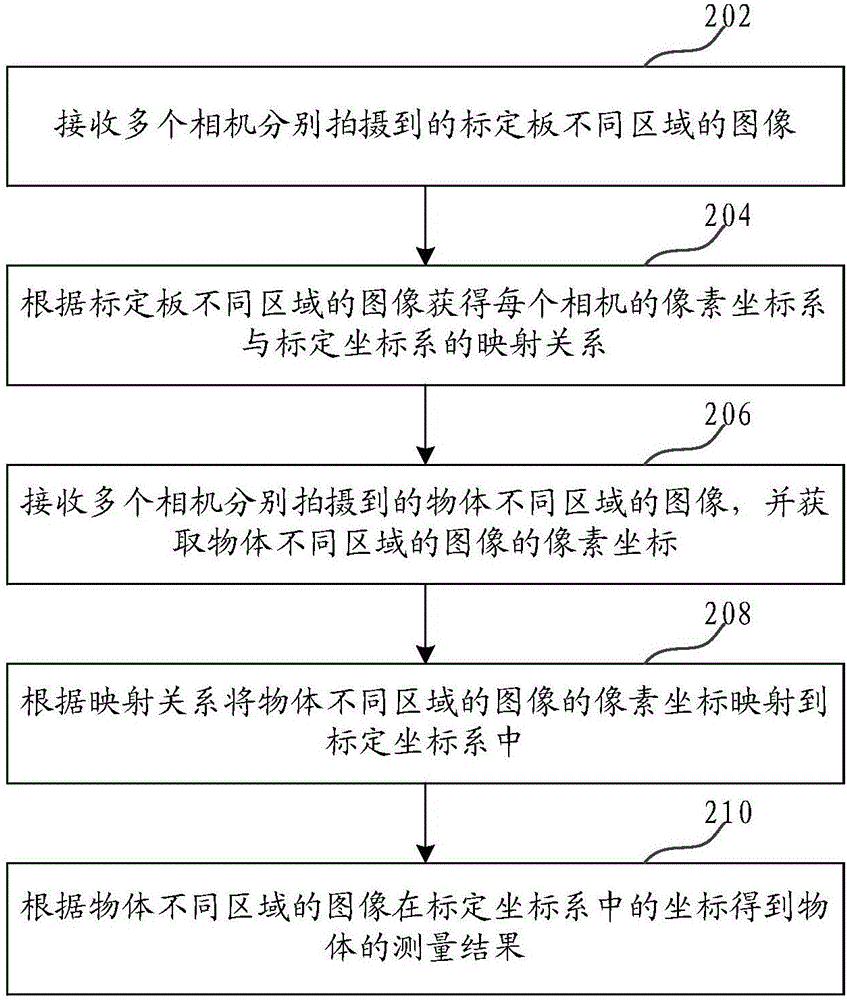

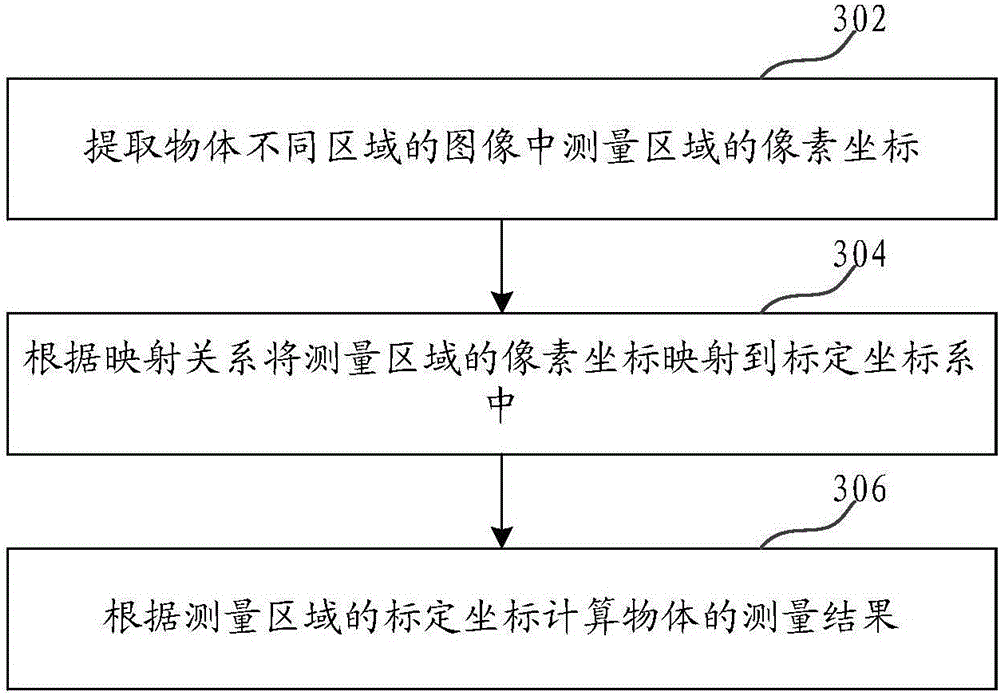

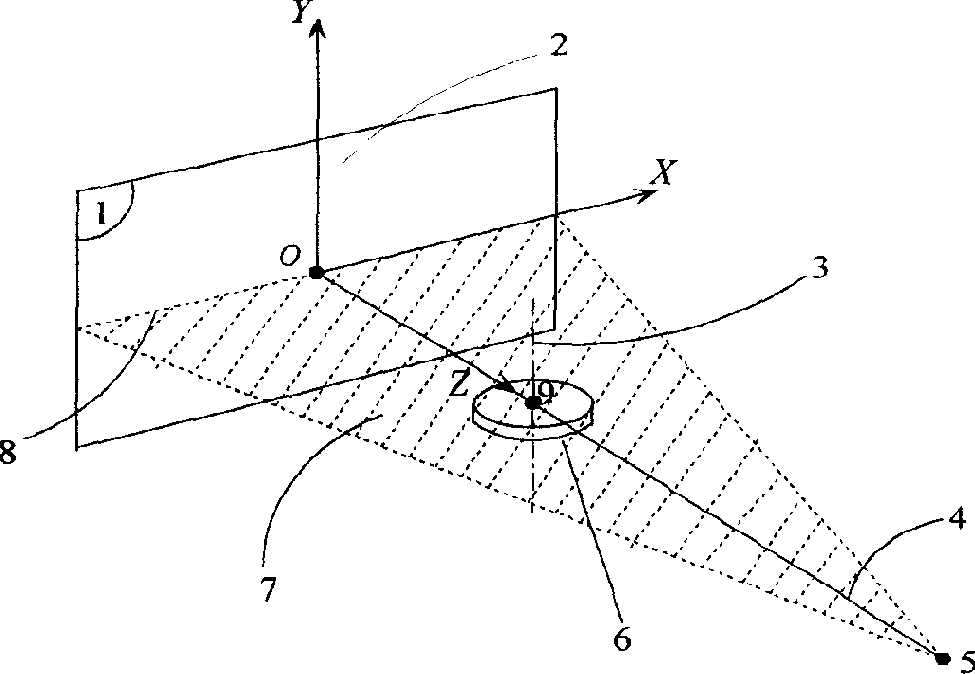

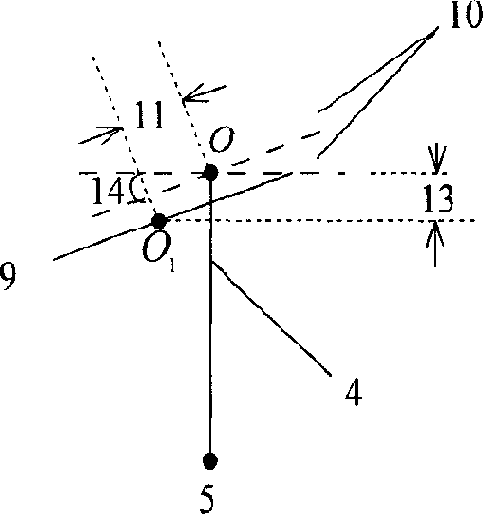

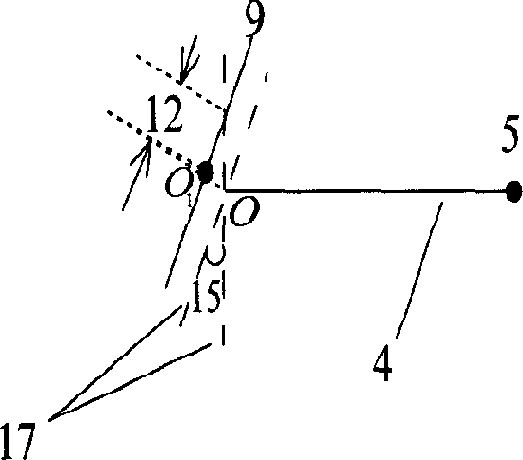

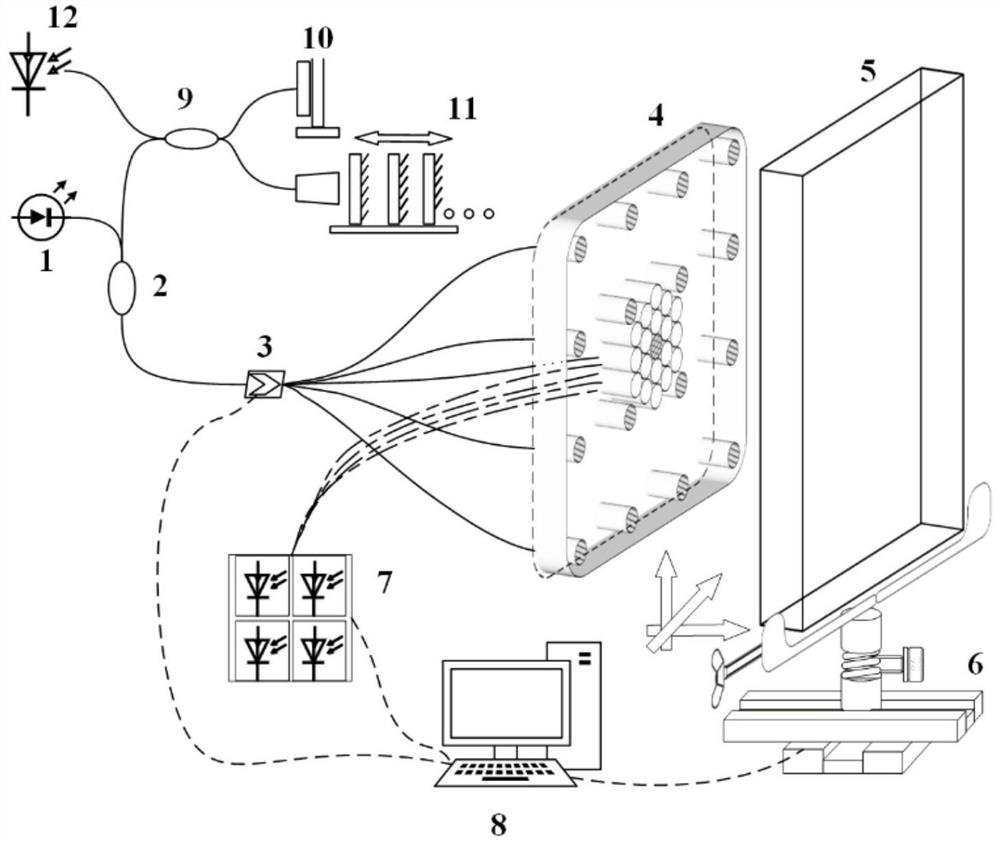

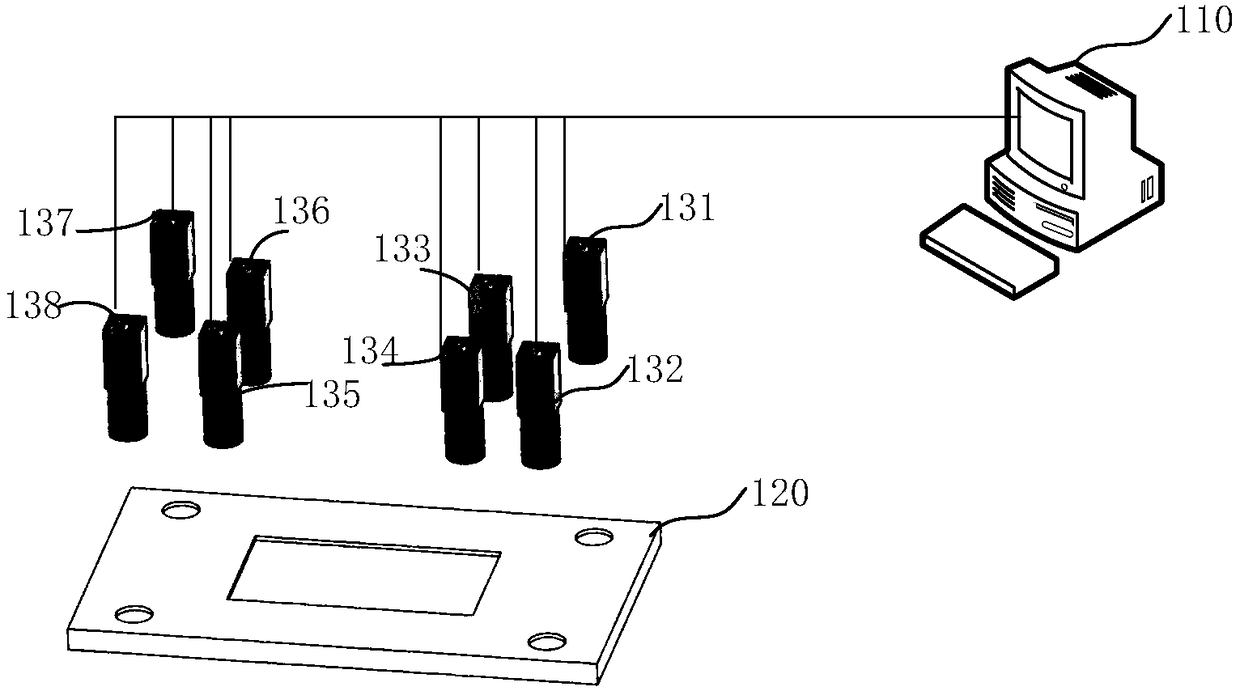

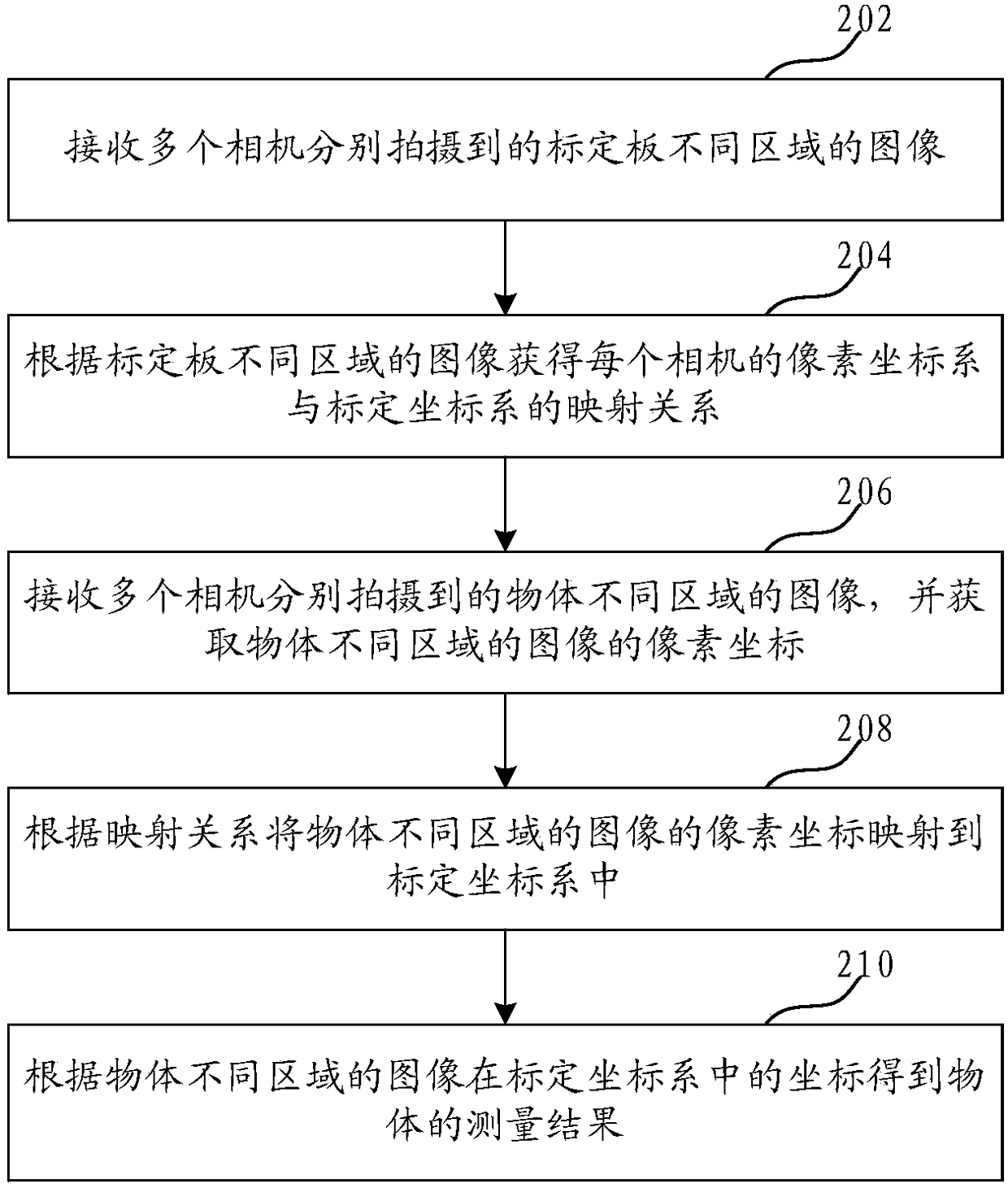

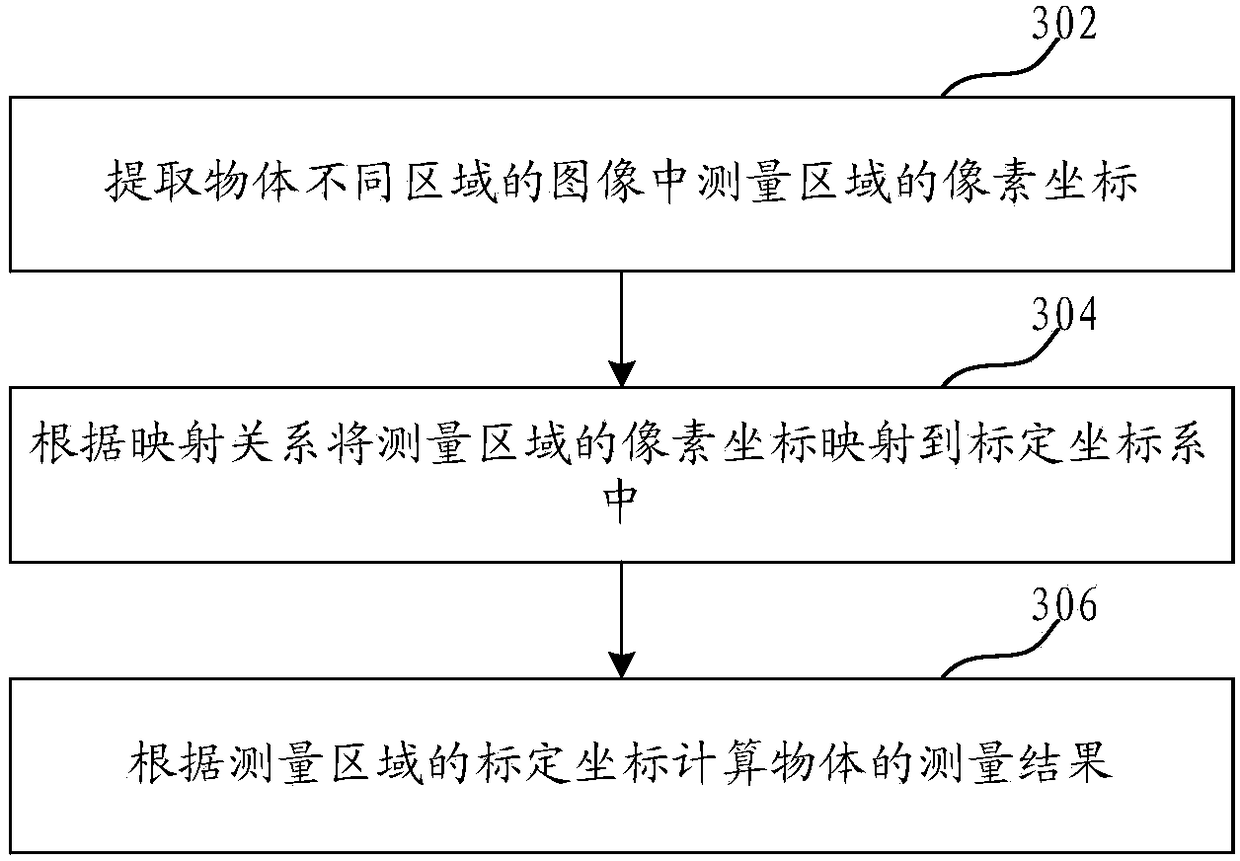

Method for measuring object through multiple cameras and device thereof

The invention relates to a method for measuring an object through multiple cameras and a device thereof. The method comprises the steps that images of different areas of a calibration board photographed by multiple cameras respectively are received; the mapping relation between the pixel coordinate system of each camera and a calibration coordinate system is acquired according to the images of different areas of the calibration board; the images of different areas of an object photographed by the multiple cameras respectively are received, and the pixel coordinates of the images of different areas of the object are acquired; the pixel coordinates of the images of different areas of the object are mapped to the calibration coordinate system according to the mapping relation; and the measurement result of the object is obtained according to the coordinates of the images of different areas of the object in the calibration coordinate system. Therefore, the object or the cameras does / do not need to be rotated or moved so that mechanical error caused by rotation or movement of the cameras can be avoided, and accuracy of the object measurement result can be enhanced.

Owner:HANS LASER TECH IND GRP CO LTD +1

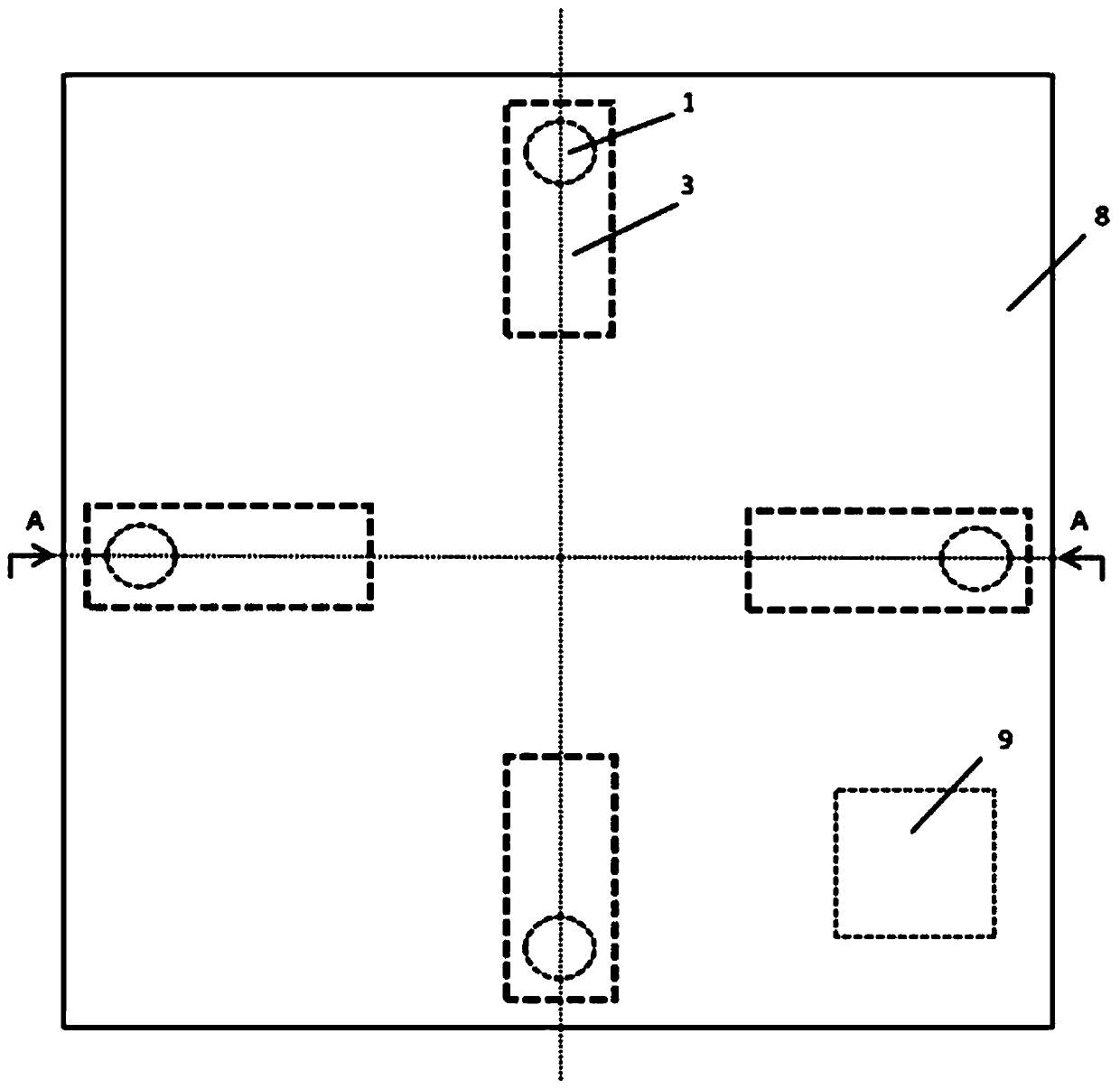

Scale template used for pyramidal tract x-rays CT system

A calibrating template for the conic-beam X-ray CT system is prepared through inlaying 4 point-shaped metallic balls in the 4 apex points of a quadrate on an organic glass or drilling 4 orifices at said 4 apex points on a metallic plate. The projection data of said calibrating template is acquired under a projecting angle and then used in conjuction with the central coordinates of the projected light spot and the side length of said quadrate to correctly calculate 6 offset parameters of said CT system of calibrating its imaging unit.

Owner:DALIAN UNIV OF TECH

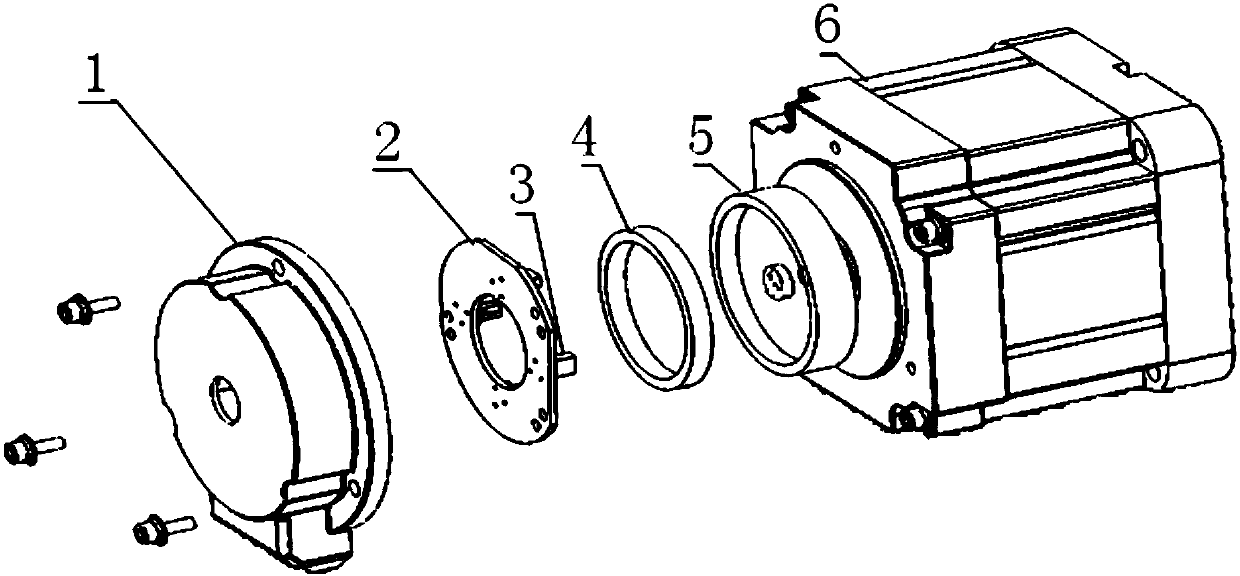

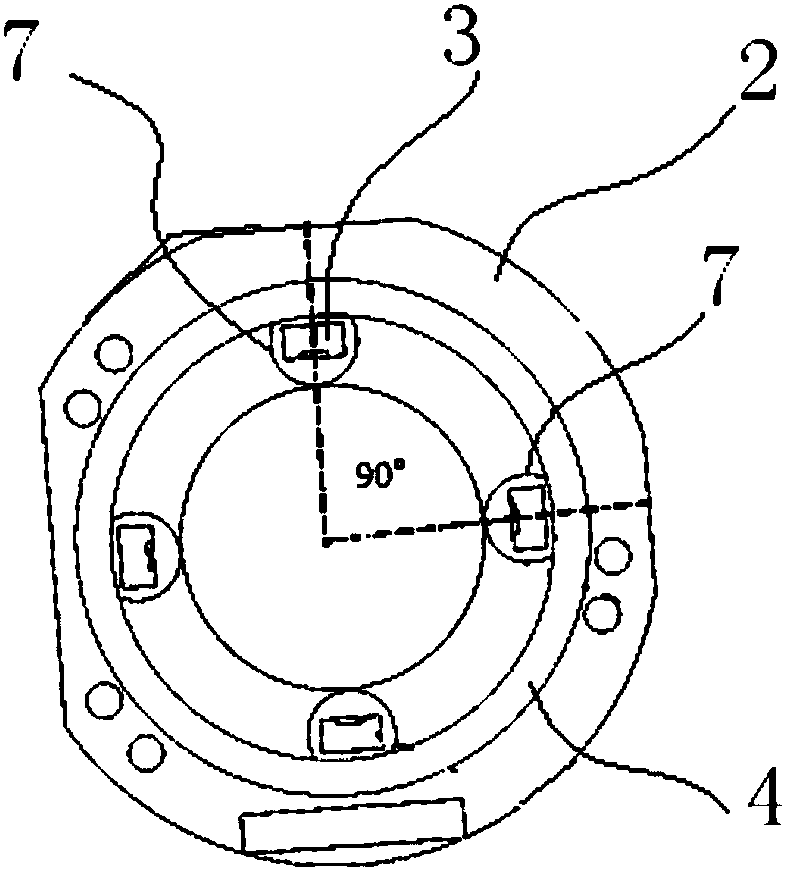

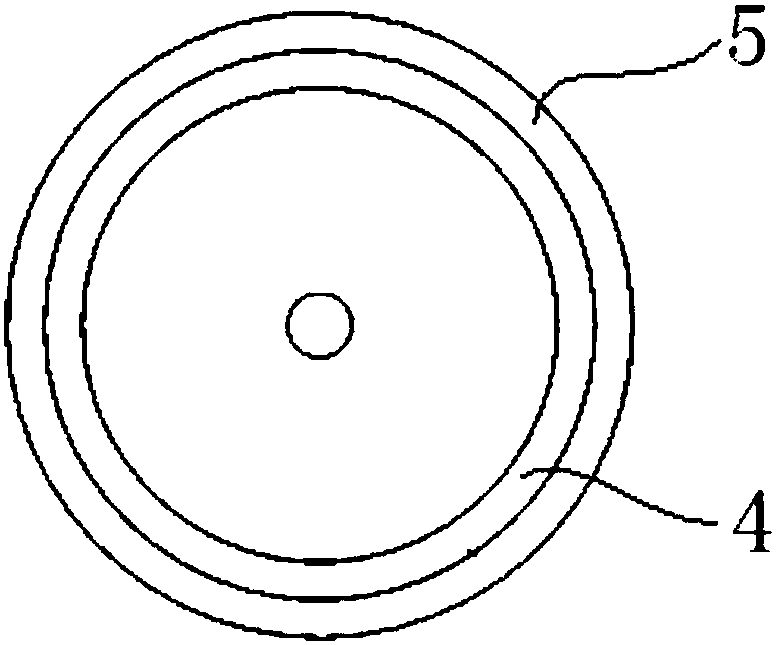

Magnetic encoder, motor and angle calculation method of motor

InactiveCN107565762AEasy to useImprove signal output accuracyStructural associationConverting sensor output electrically/magneticallyHall elementControl circuit

The invention provides a magnetic encoder, a motor and an angle calculation method of the motor. The magnetic encoder comprises a magnetic conducting disk, annular magnet steel fixed in the magnetic conducting disk and an encoder plate, wherein four linear hall elements which are uniformly distributed in the circumferential direction are arranged on the surface of the encoder plate; all linear hall elements are located in a cavity enclosed by the annular magnet steel; and the encoder plate is provided with an encoder algorithm control circuit connected with all linear hall elements. The annular magnet steel is fixed in the magnetic conducting disk and the linear hall elements are arranged in the annular magnet steel, so that the maximum anti-interference performance is achieved and the signal output accuracy of the linear hall elements is improved.

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

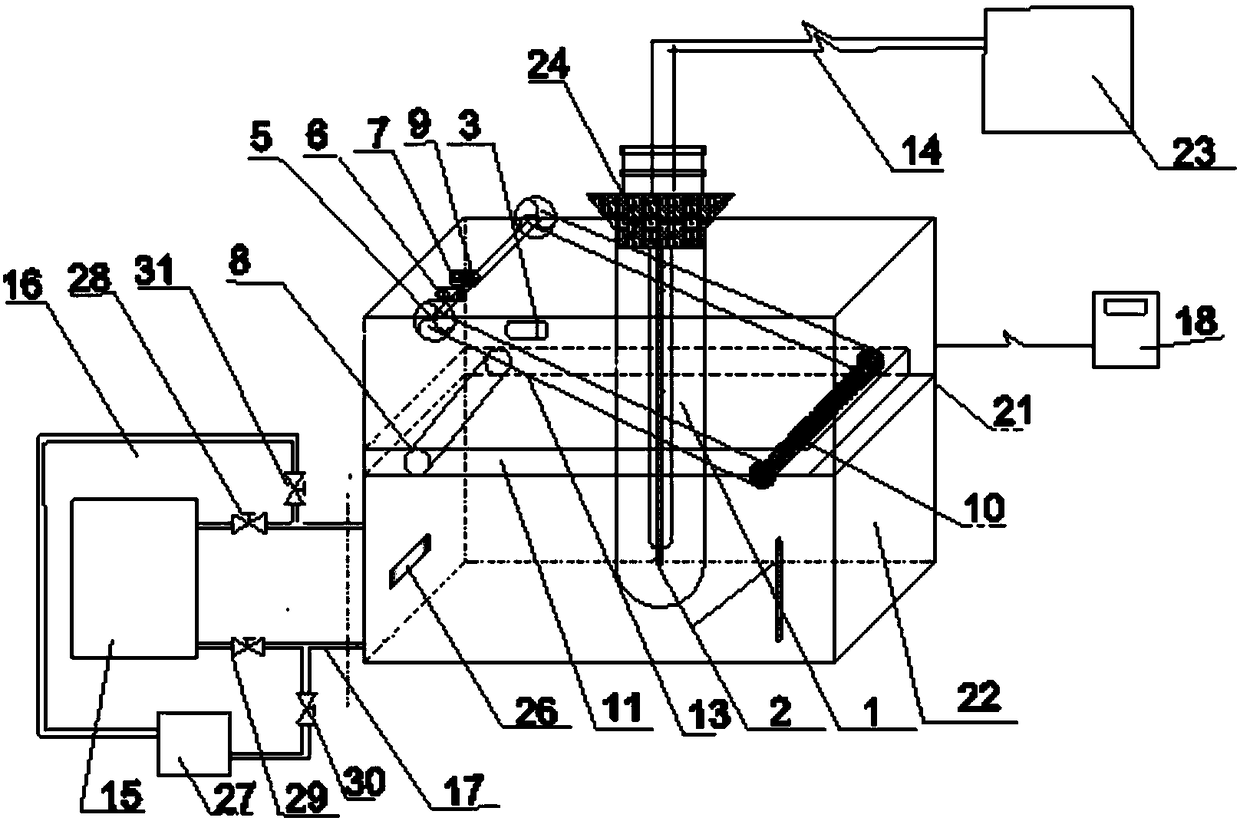

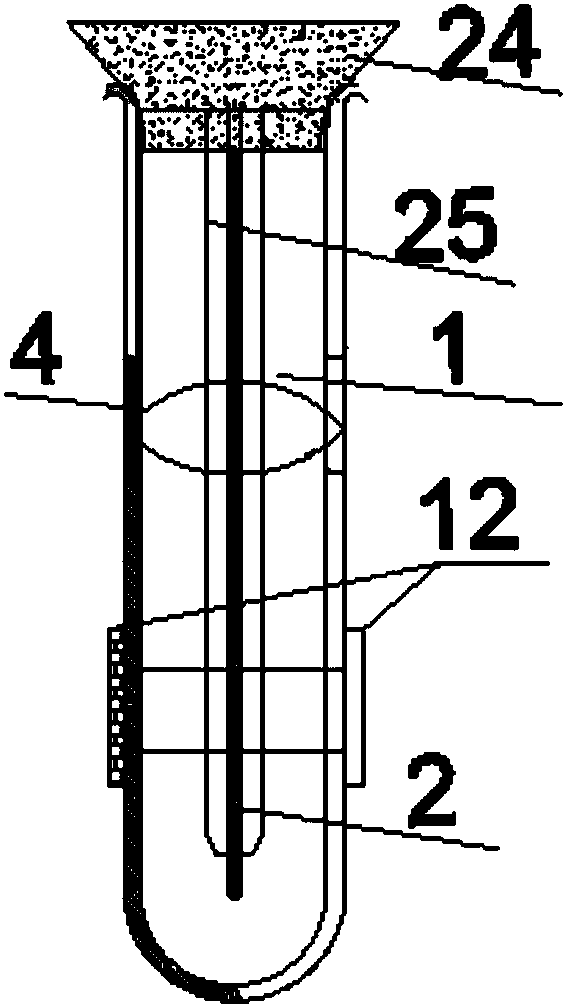

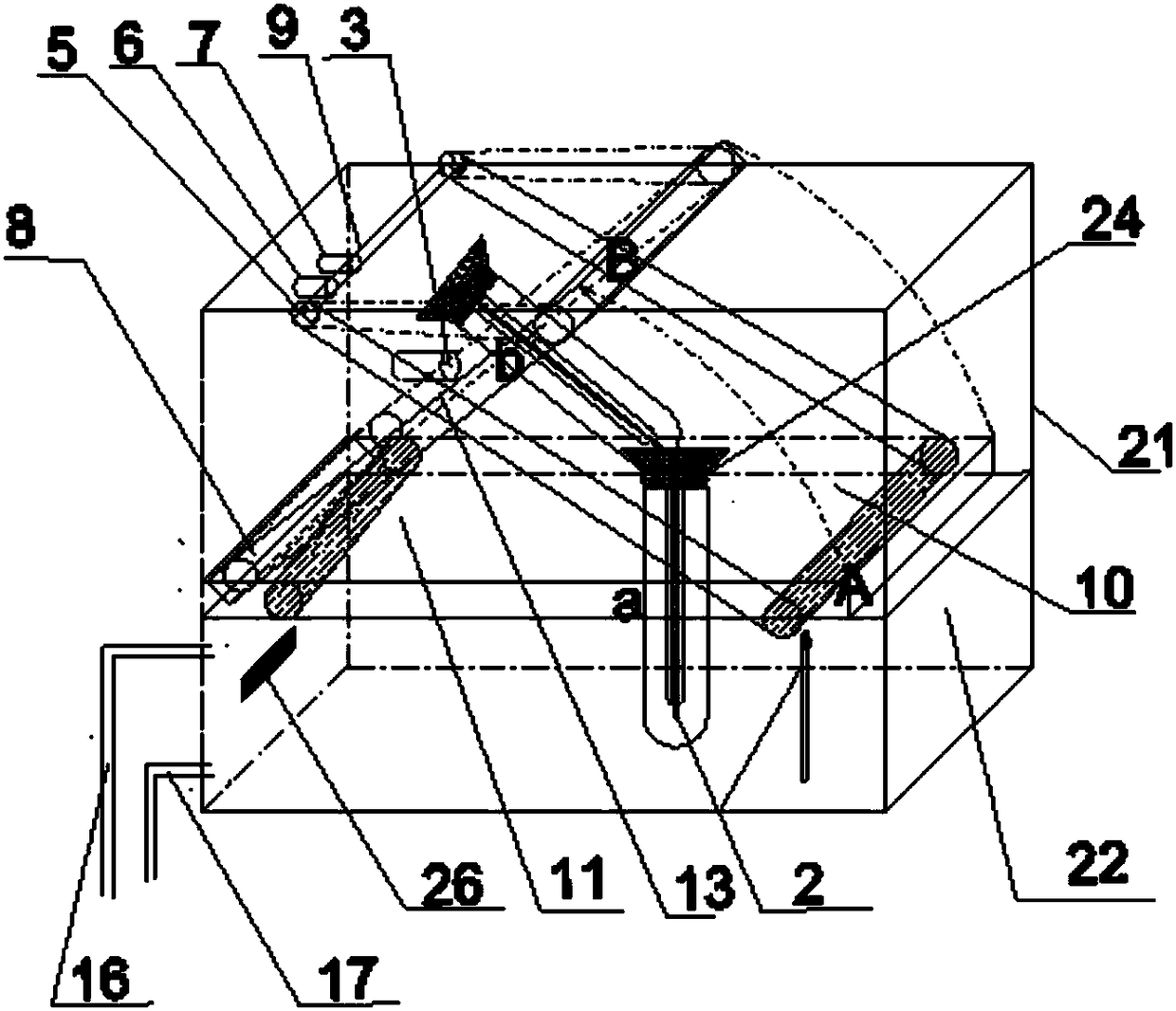

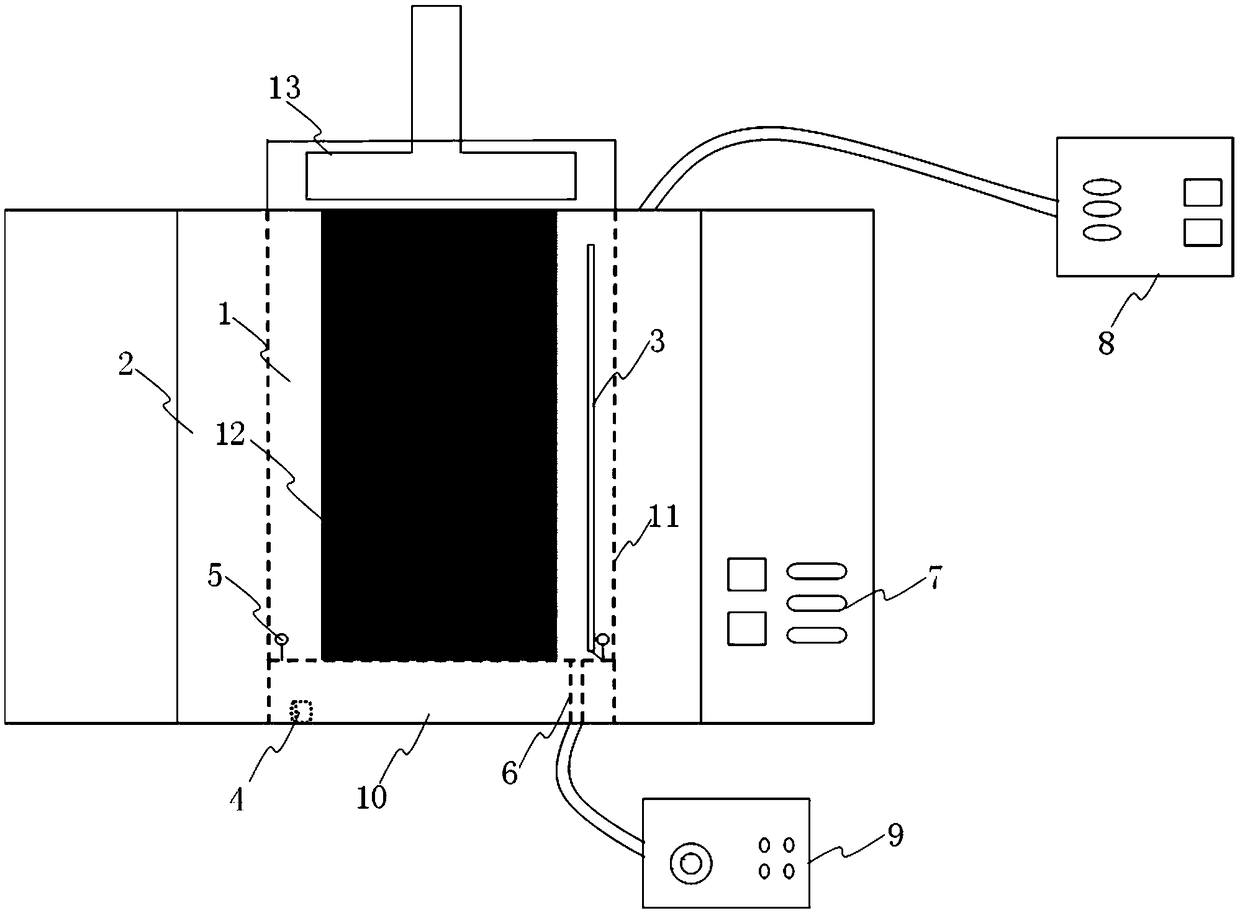

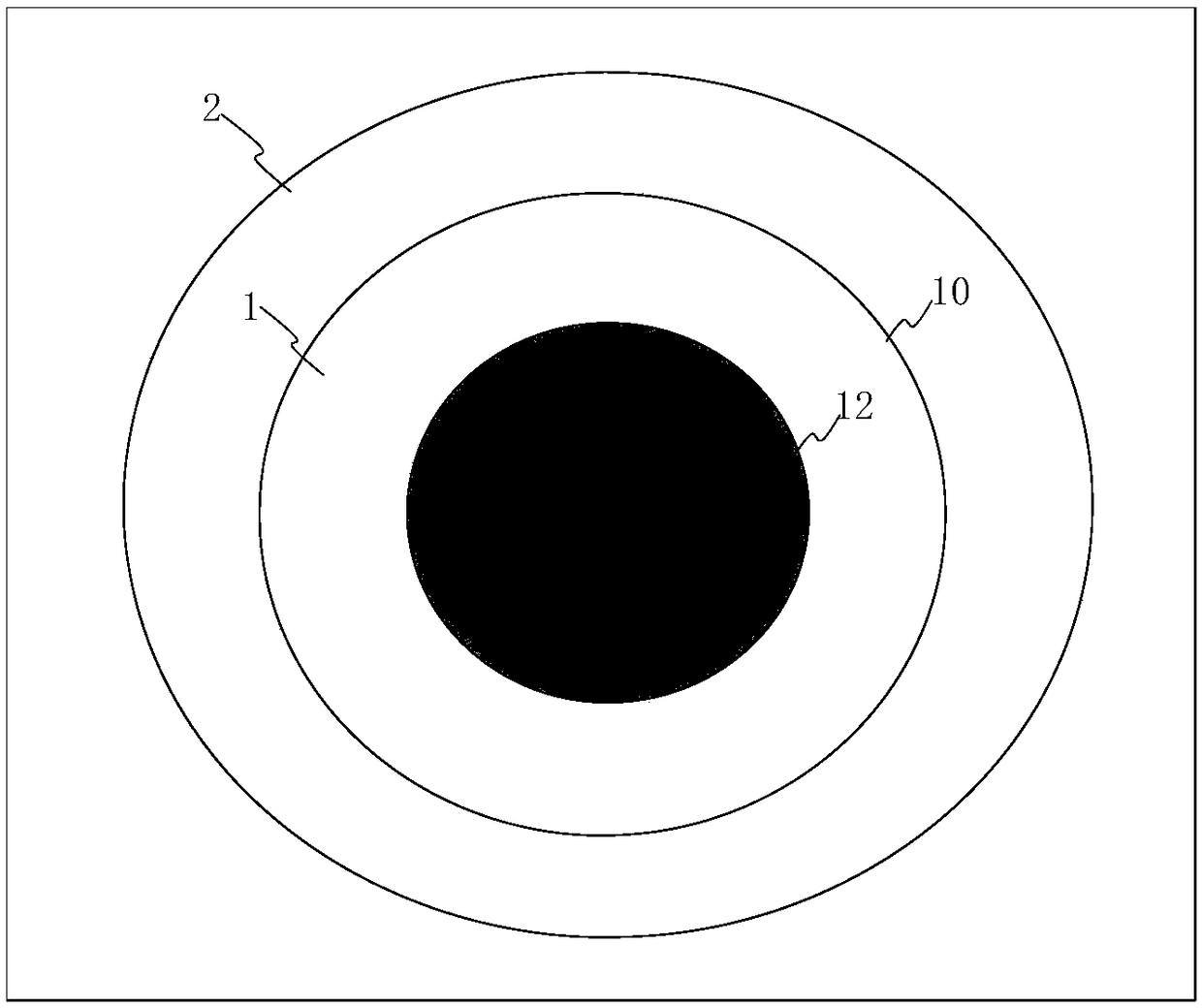

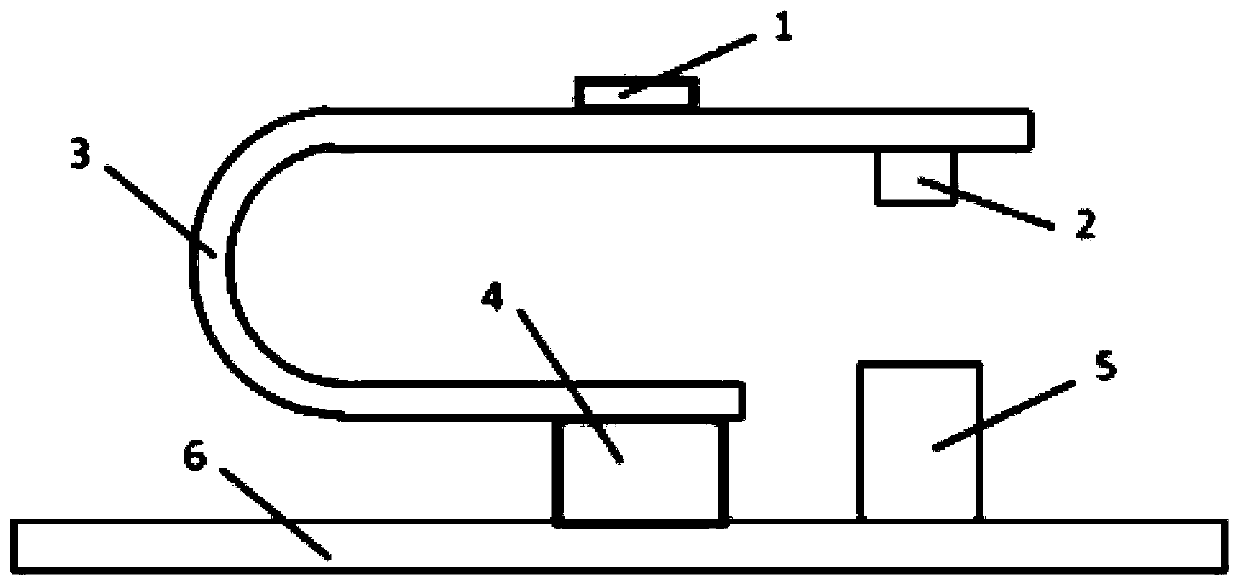

Full-automatic condensation point measuring device and method

InactiveCN108593701AAvoid mechanical errorsReduce mechanical errorsInvestigating phase/state changeCircular loopPhysical property

The invention discloses a full-automatic condensation point measuring device, and belongs to the technical field of oil physical property measurement. The measuring device adopts two measuring modes to measure oil condensation points and comprises a condensation point test tube, a temperature sensor, a camera probe, a stress piece, a motor, a position sensor, an angle sensor, a heating-refrigeration circulator, a PC machine, a PLC controller, a modulation processor and an injection pump, the heating-refrigeration circulator, a liquid tank and a liquid storage pot are connected and form a circular loop, and the stress piece is inlaid in the inner wall of the condensation point test tube; the camera probe monitors and judges solidification degree of a sample, is placed to the condensation point tube, and rotates to the 45-degree oil sample scale line position, when the motor drives the condensation point test tube to rotate, the camera probe and the stress piece synchronously measure oil, the efficiency is high, the reliability is high, human resources are greatly reduced in a technical aspect, and the measuring device belongs to a high-performance intelligent automatic device.

Owner:CHANGZHOU UNIV

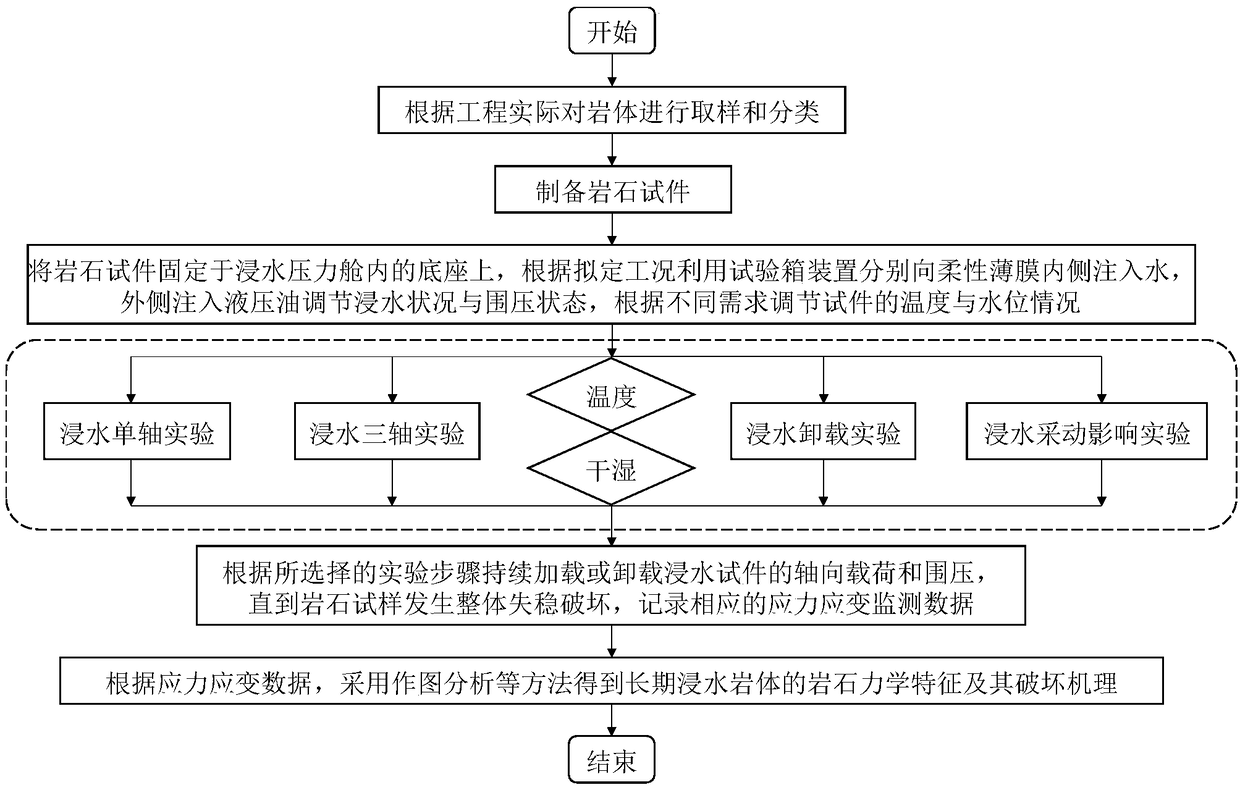

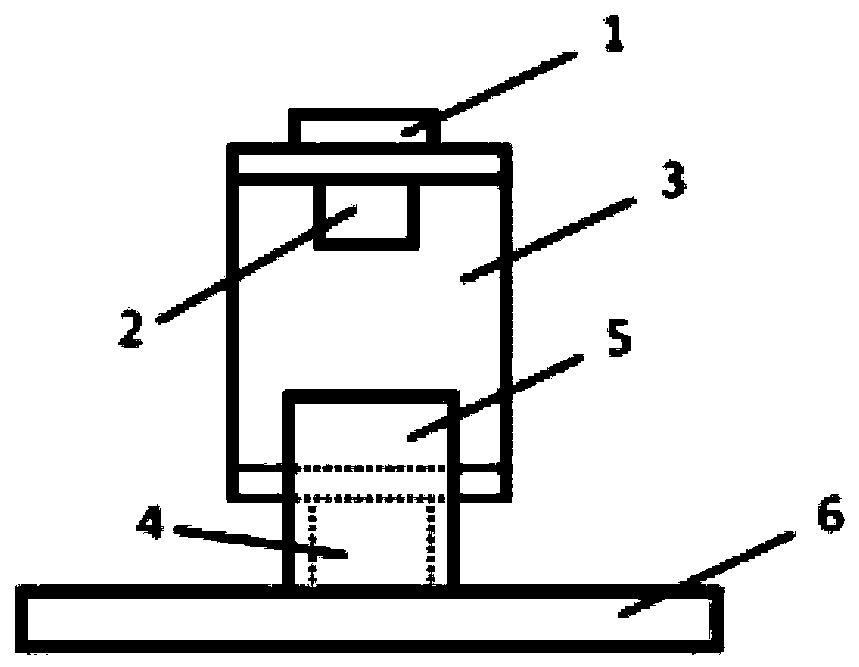

Water-oil isolation type soaking three-axis testing tank and testing method

PendingCN109470570AAvoid influenceAvoid mechanical errorsMaterial strength using tensile/compressive forcesNuclear energy generationEngineeringRefrigeration

The invention provides a water-oil isolation type soaking three-axis testing tank and a testing method, relates to the technical field of testing equipment and aims to solve the technical problem thatvariable confining pressure testing is hard to implement under a long-term soaking condition of a test part. The testing tank comprises a soaking pressure cabin, a hydraulic oil cabin, a heater, a pressure sensor, a temperature sensor, a transfusion channel, a refrigeration device, an oil pressure control device and a transfusion adjusting device, wherein the soaking pressure cabin is arranged inside the hydraulic oil cabin; a flexible film is arranged between the soaking pressure cabin and the hydraulic oil cabin; the transfusion channel is communicated with the soaking pressure cabin and the transfusion adjusting device. By adopting the device, operation such as confining pressure loading and confining pressure release is directly implemented on a test part in the soaking pressure cabin, and deformation situations of rock explored at different water full states of a mining well can be simulated. The testing tank structure provided by the invention has the advantages of being simplein structure, convenient to operate, and the like, and the testing method with the testing tank has the advantages of being small in experiment error, wide in simulation range, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

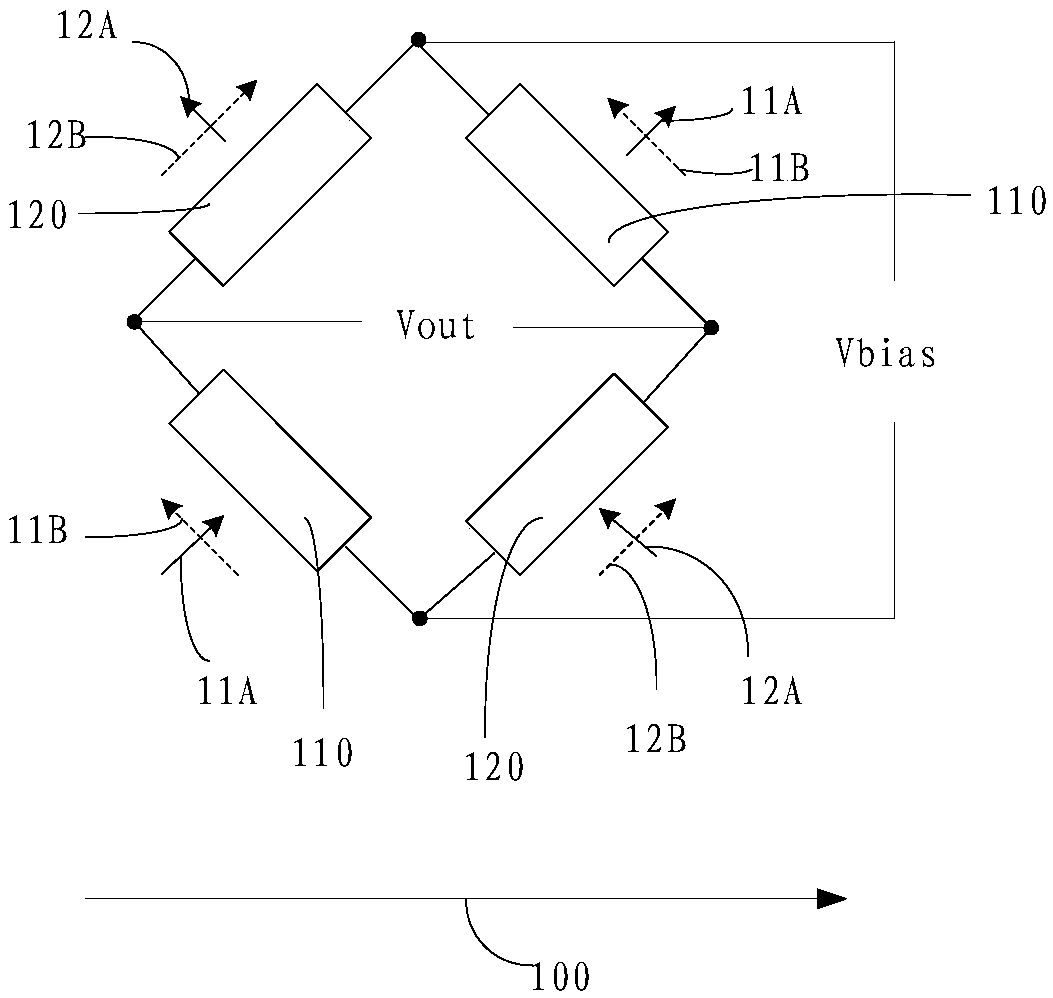

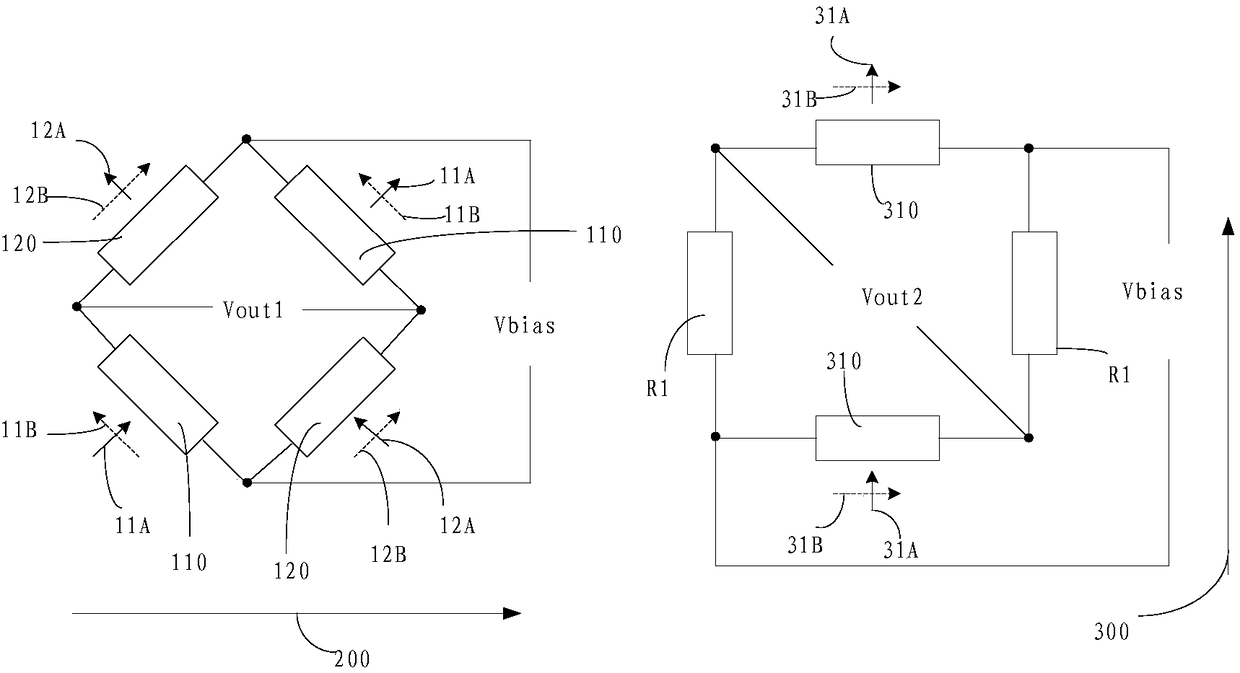

Single-axis and double-axis magnetic field sensors and preparation method thereof

PendingCN108387852AAvoid mechanical errorsReduce manufacturing costMagnitude/direction of magnetic fieldsFull bridgeComputer module

The embodiment of the invention provides a single-axis magnetic field sensor, a double-axis magnetic field sensor and a preparation method thereof. The single-axis magnetic field sensor comprises a first full-bridge circuit arranged on a substrate. The first full-bridge circuit comprises two first magnetic resistance modules and two second magnetic resistance modules. The two first magnetic resistance modules are located on a pair of opposite bridge arms of the first full-bridge circuit respectively. The two second magnetic resistance modules are located on the other pair of opposite bridge arms of the first full-bridge circuit respectively. The magnetization directions of the reference layers of the first magnetic resistance modules are perpendicular to the magnetization directions of thefree layers of the first magnetic resistance modules. The magnetization directions of the reference layers of the first magnetic resistance modules are the same. The magnetization directions of the reference layers of the second magnetic resistance modules are perpendicular to the magnetization directions of the free layers of the second magnetic resistance modules. The magnetization directions of the reference layers of the second magnetic resistance modules are the same. The included angle between the magnetization directions of the reference layers of the first magnetic resistance modulesand the magnetization directions of the reference layers of the second magnetic resistance modules is A and A is larger than 0 degree and smaller than 180 degrees. The technical scheme provided by theinvention has the advantages of simple process, low manufacturing cost and the like. The product yield can be improved, and the large-scale production requirement can be met.

Owner:QINGDAO RES INST OF BEIHANG UNIV +1

Counting apparatus of photosensitive gray scale

InactiveCN102426028AAvoid mechanical errorsAvoid errorsConverting sensor output opticallyMicrocomputerMicrocontroller

The invention relates to a counting apparatus of a photosensitive gray scale. The counting apparatus comprises a plurality of counting print wheels corresponded to different unit amounts and all the counting print wheels are connected with a drive unit. Different gray scale segments that are different from shallow to deep are arranged at an arc surface or a side surface of each of the counting print wheel, and all the gray scale segments are in end-to-end connection. Meanwhile, at least one support is arranged at a position that is corresponded to the arc surface or the side surface of each of the counting print wheel as well as is provided with a photosensitive sensor and a luminescent device; each of the photosensitive sensor is configured with at least two luminescent devices; and the photosensitive sensors and the luminescent devices are connected with a one-chip microcomputer. According to the invention, defects of other sensing modes can be overcome, wherein the defects include a requirement on complex determination, easiness to make errors of carrying critical points and easiness of wearing and corrosion of resistor sensing contacts and the like; photosensitive sensors are used to carry out non-contact detection on different gray scales, so that purposes of print wheel numerical code determination and print wheel data reading are achieved.

Owner:SHANDONG WEIWEI TECH

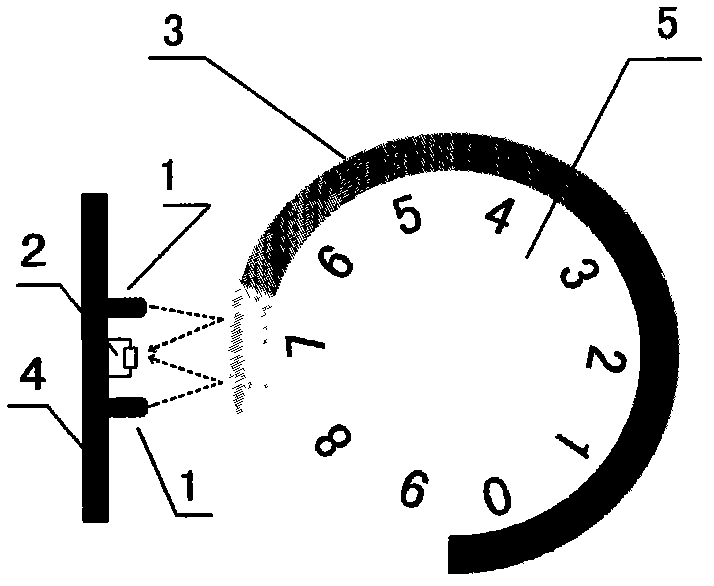

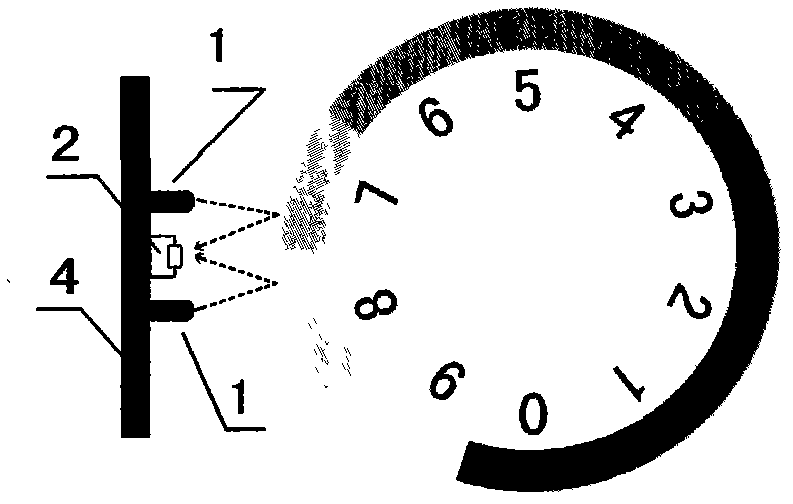

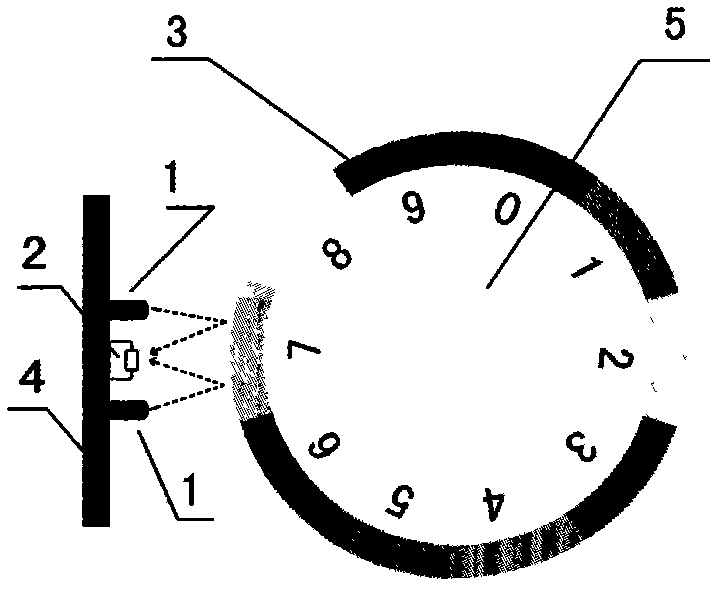

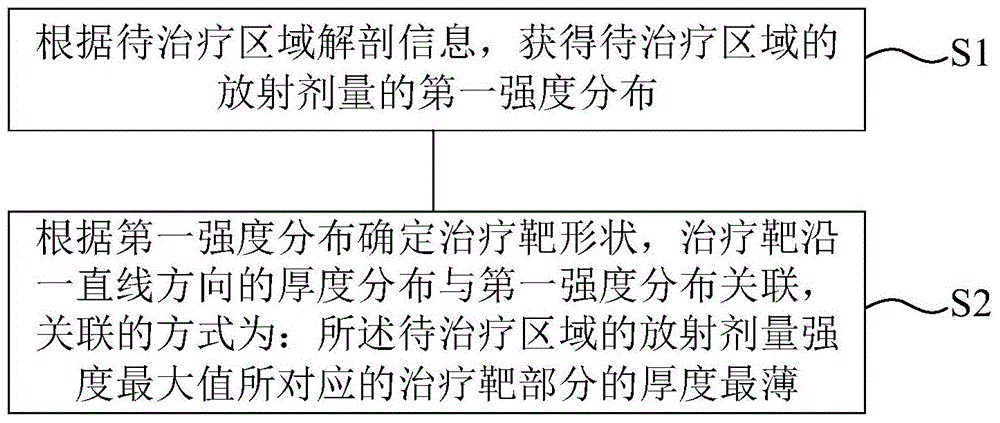

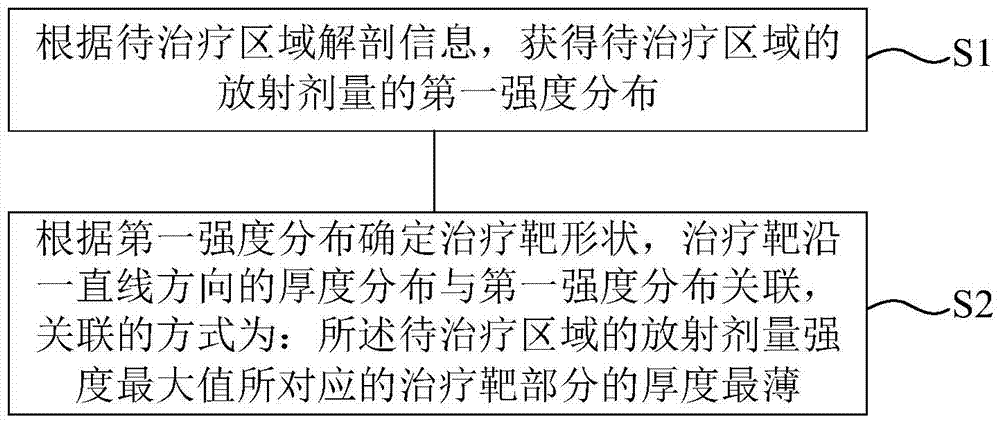

Radiological treatment equipment, therapeutic target, manufacturing method of therapeutic target and radiological treatment method

ActiveCN104474639AExtended propagation distanceShorten the propagation distanceX-ray/gamma-ray/particle-irradiation therapyUltimate tensile strengthTherapeutic Area

The invention relates to radiological treatment equipment, a therapeutic target, a manufacturing method of the therapeutic target and a radiological treatment method. The thickness distribution of the therapeutic target along a linear direction is correlated with the distribution of the radiological dose intensity in an area to be treated, wherein the correlation mode lies in that the dose intensity of first intensity distribution is inversely correlated with the thickness of the therapeutic target along a linear direction. In the radiological treatment process, the radiological dose intensity of treatment ray transmitting from the thinnest part of the therapeutic target is highest so as to realize radiological treatment. According to the scheme, through improving the therapeutic target per se to realize the purpose of intensifying therapeutic ray, no extra intensifying equipment is introduced, and the errors caused by the intensifying equipment can be avoided so as to ensure that the dose intensity distribution of actual therapeutic ray meets the preset dose intensity distribution requirement. In addition, the therapeutic target solves the problem that existing intensifying equipment is complicated in structure, high in fault rate and high in maintenance cost, and is simple in self structure and relatively low in production cost.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

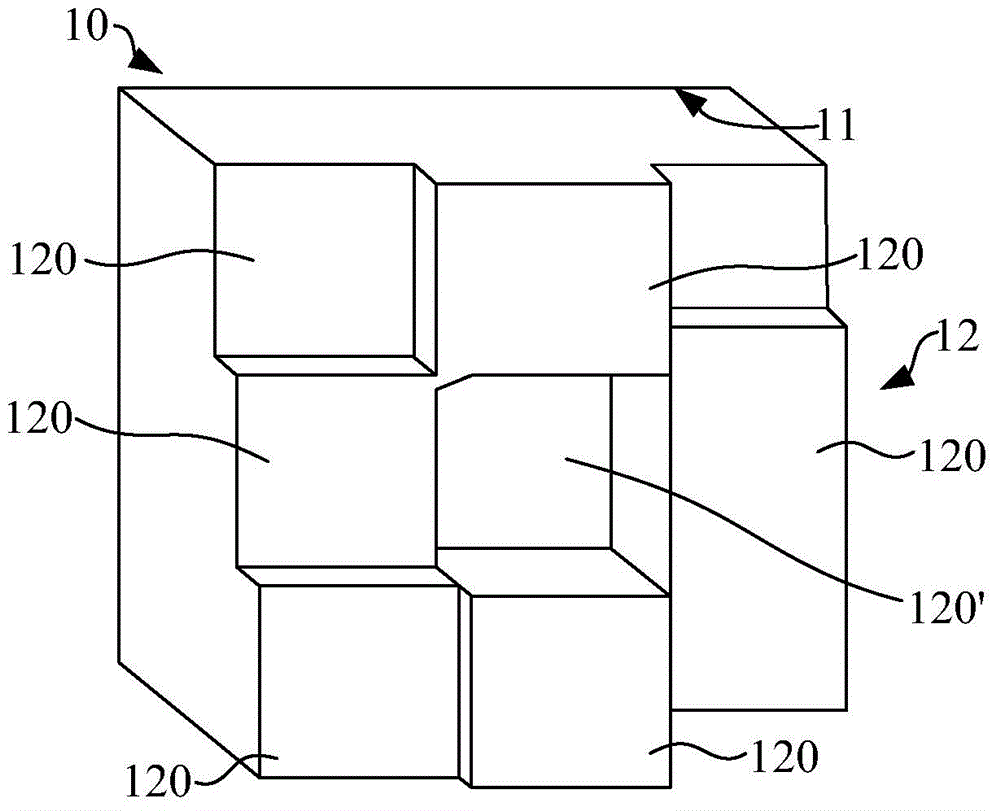

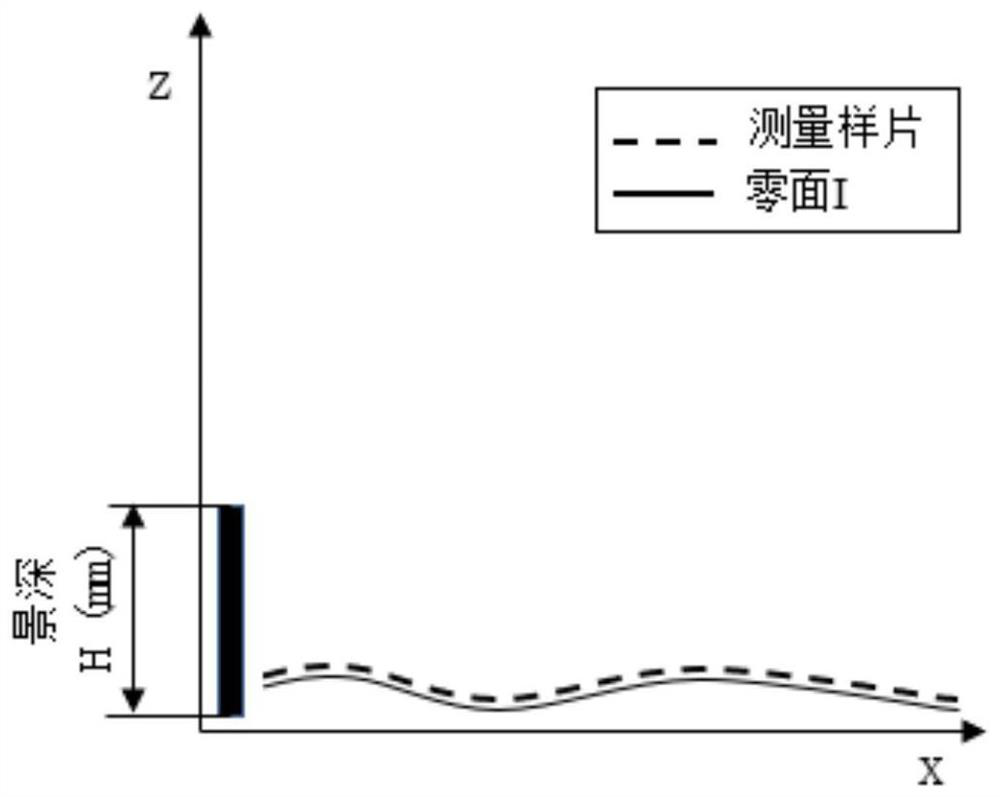

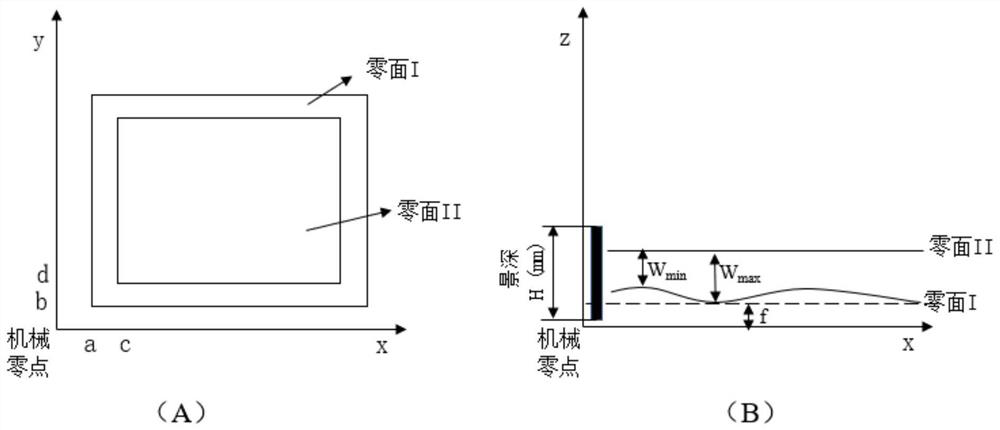

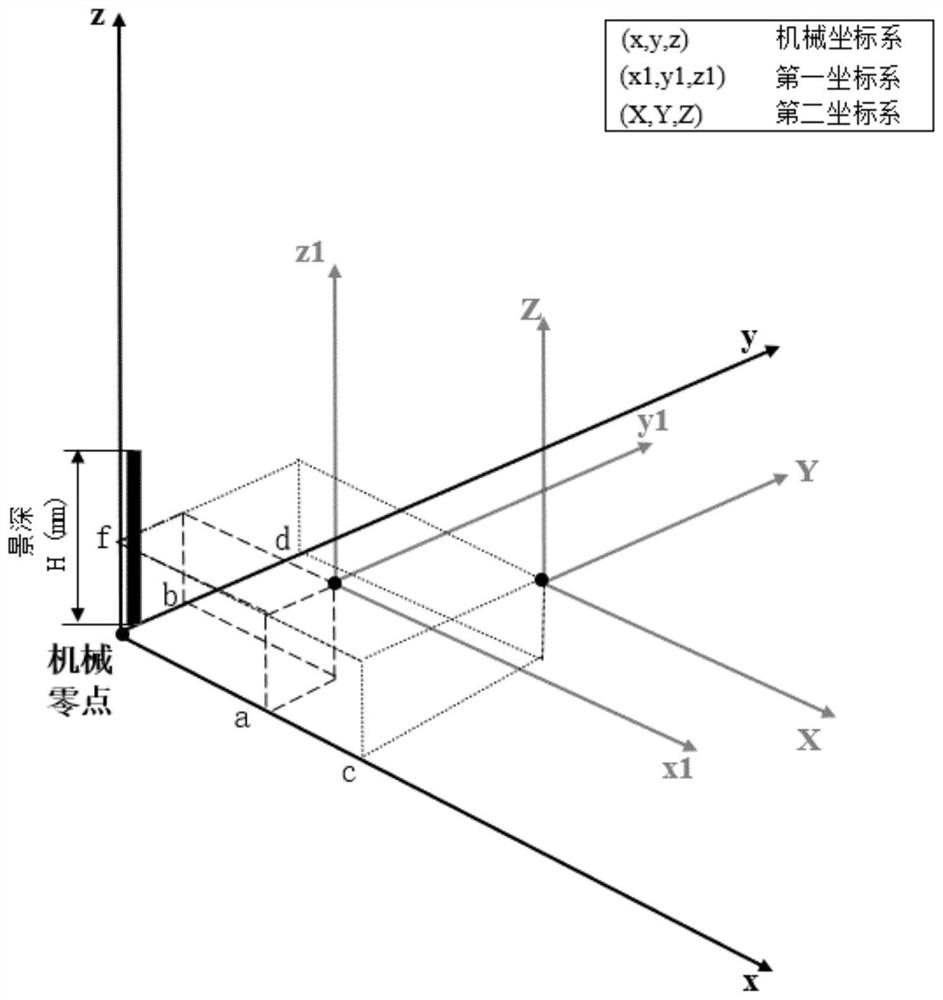

Method and system for measuring warping degree of liquid crystal substrate glass

ActiveCN113155023AAvoid mechanical errorsAccurate measurementUsing optical meansThree-dimensional spaceEngineering

The invention provides a method and a system for measuring a warping degree of liquid crystal substrate glass, and belongs to the field of liquid crystal substrate glass. The warping degree measuring method comprises the following steps: delimiting a working area on a bearing platform, and delimiting a measuring area in the working area; obtaining three-dimensional coordinates of a working area surface, wherein the working area surface is a zero surface I; based on the three-dimensional coordinates of the zero surface I, determining the three-dimensional coordinates of a track surface of a measuring lens moving in the measuring area surface, wherein the track surface is a zero surface III, the zero surface III is parallel to the zero plane I in a three-dimensional space, and the zero surface III is in a range of depth of field H mm of the measuring lens, and H is greater than 0 mm; in a sample wafer measurement process, planning the measuring lens to move according to the three-dimensional coordinate points of the zero surface III, and collecting the three-dimensional coordinates of the sampling points on a sample wafer in real time; and calculating the vertical distance from each sampling point to the zero surface III, and calculating the warping degree value of the sample wafer according to the vertical distance. According to the method, the mechanical error of the zero surface I can be eliminated, and a measurement result is more accurate.

Owner:甘肃旭盛显示科技有限公司 +2

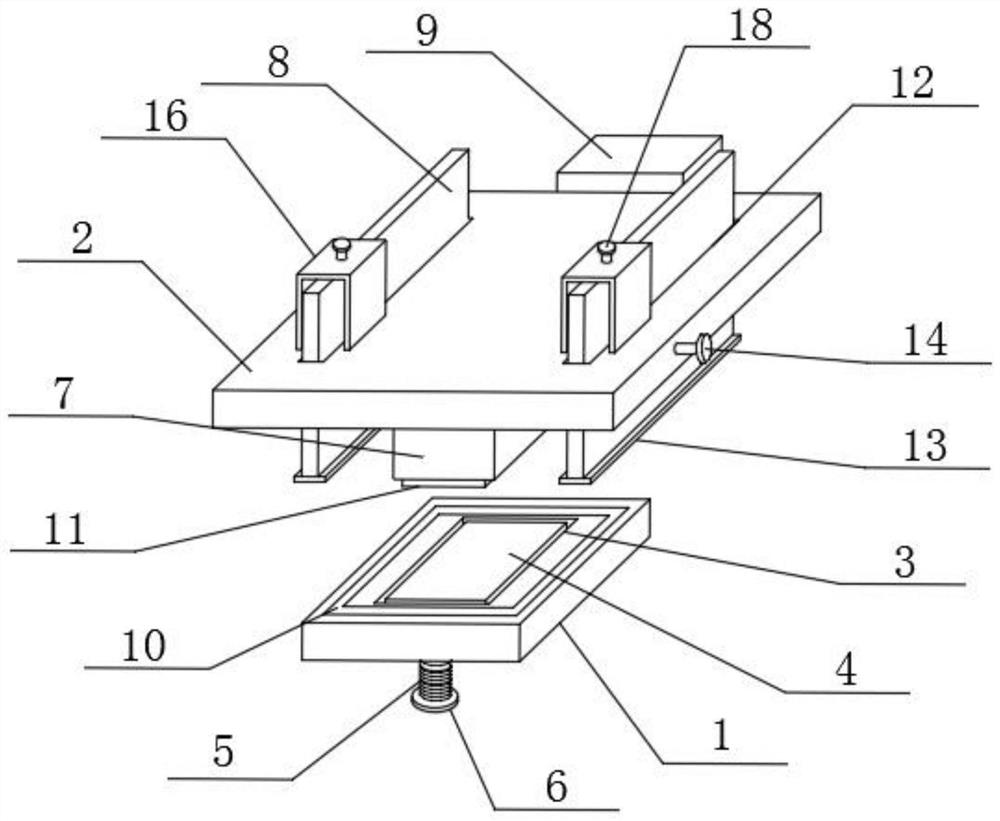

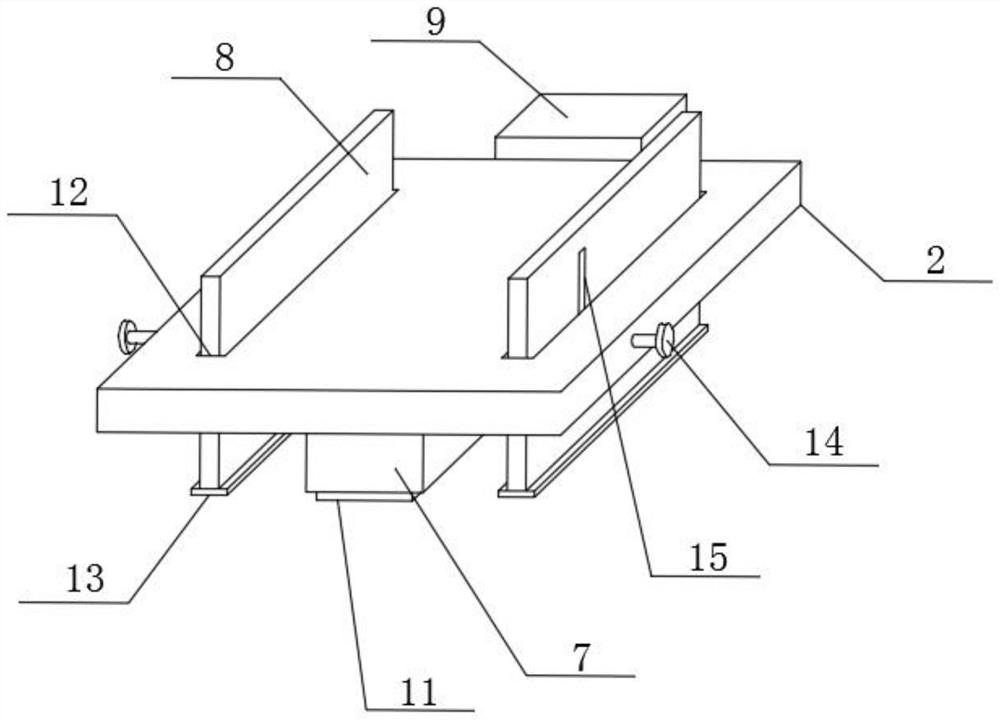

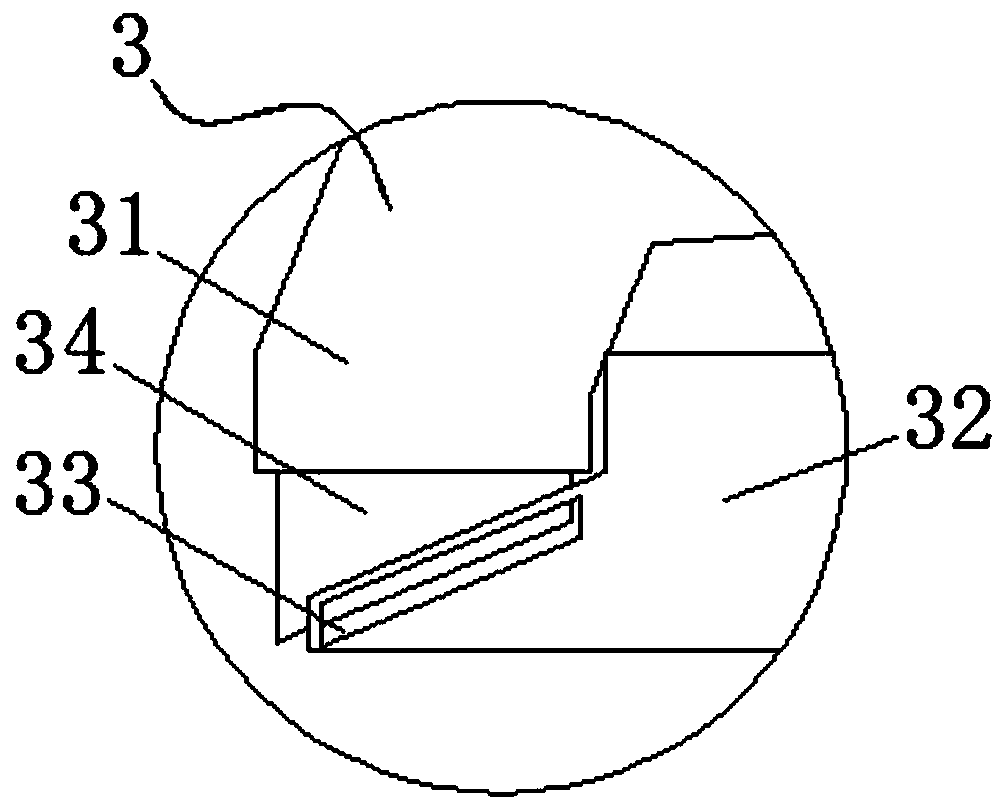

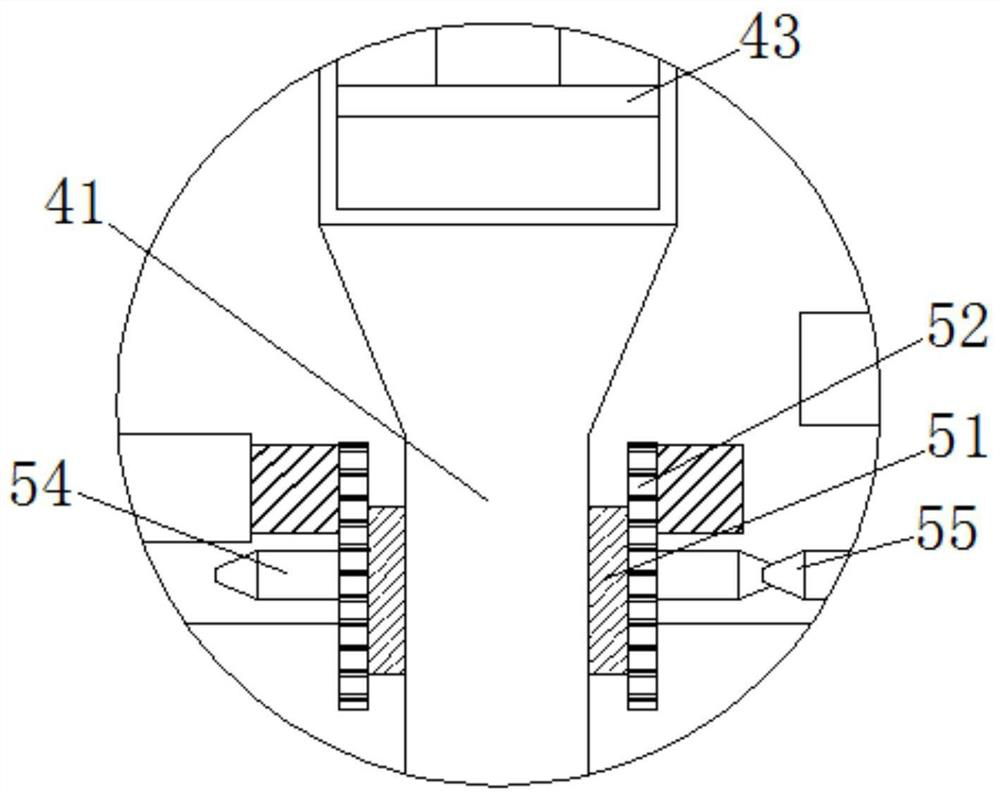

Microscope focusing device based on ultrasonic motor drive

ActiveCN104950430ARealize electric controlSimple structureMicroscopesReciprocating motionEngineering

The invention discloses a microscope focusing device based on ultrasonic motor drive. An ultrasonic motor, bevel gears and bevel racks cooperate with one another to electrically control a support plate to move up and down, and the structure is very simple. During usage, the support plate can be controlled to move on any scale under the drive of the ultrasonic motor, so that the clearest focal length can be found out easily. The ultrasonic motor has no inertia during reciprocating, meanwhile, one adjusting mechanism is arranged between one bevel gear and the ultrasonic motor, one adjusting mechanism is arranged between the other bevel gear and an encoder, the bevel gears and the bevel racks can be always meshed closely by the aid of the adjusting mechanisms, and mechanical errors of a traditional structure are avoided when the support plate is controlled to move up and down. The ultrasonic motor, the bevel gears and the bevel racks cooperate with one another, the kinematic accuracy of the support plate is up to plus / minus 2 mu m through experiments, and the focusing accuracy of the focusing device is much higher than that of a traditional focusing structure.

Owner:苏勋涛 +1

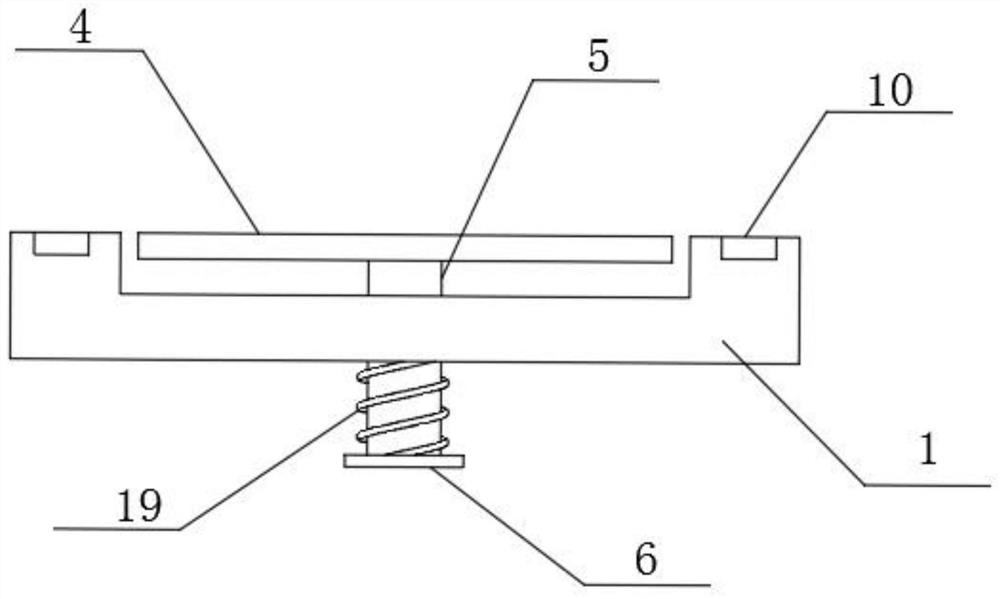

Multifunctional test bench for chip

PendingCN112130059AFit tightlyAids in detectionElectronic circuit testingShort-circuit testingStructural engineeringTest bench

The invention discloses a multifunctional test bench for a chip. The multifunctional test bench comprises a test bench and an extrusion plate, wherein a groove is formed in the middle of the upper surface of the top of the test bench; a detection plate is arranged in the groove; an insertion rod is arranged in the middle of the bottom surface of the test bench; a connection ring is arranged at thebottom end of the insertion rod; a connection block is mounted in the middle of the bottom surface of the extrusion plate; and limiting plates are arranged at positions, close to two sides, in the extrusion plate; and a detector is mounted on the rear surface of the extrusion plate. According to the multifunctional test bench for the chip, the chip can be limited through the limiting plates, so that the chip is prevented from being cracked by the extrusion plate due to a mechanical error; through springs and the insertion rod, the chip can be separated and taken out from the test bench; and the whole test bench is simple in structure, relatively practical and suitable for popularization.

Owner:复汉海志(江苏)科技有限公司

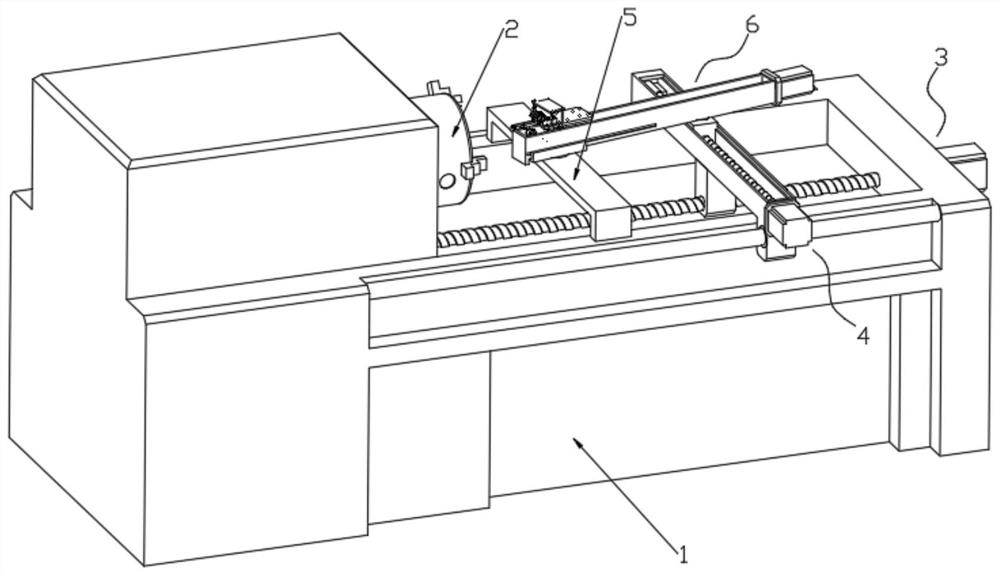

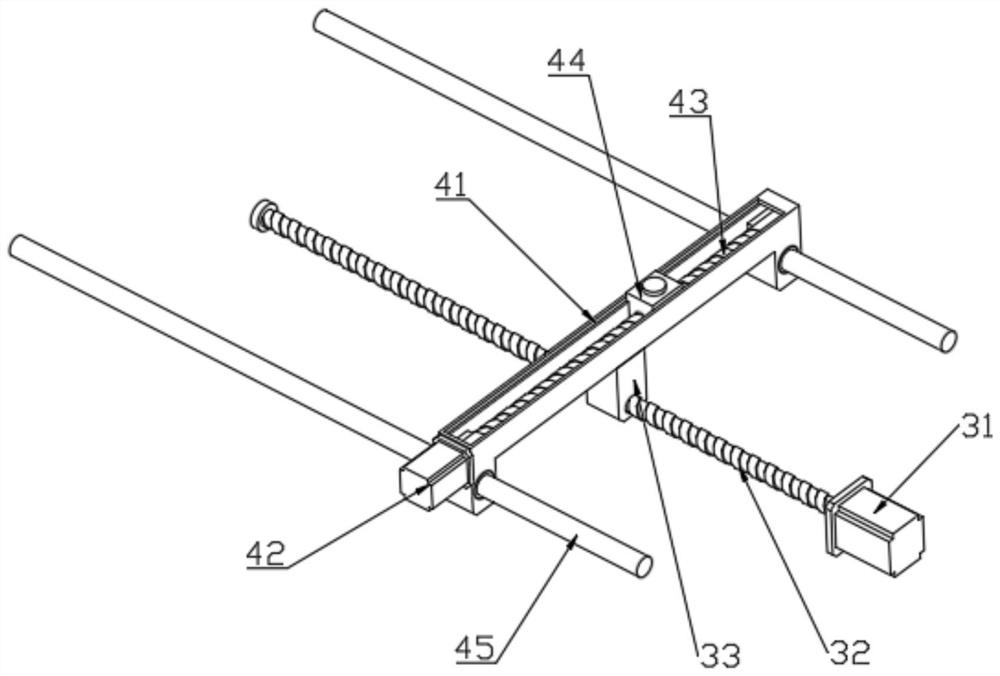

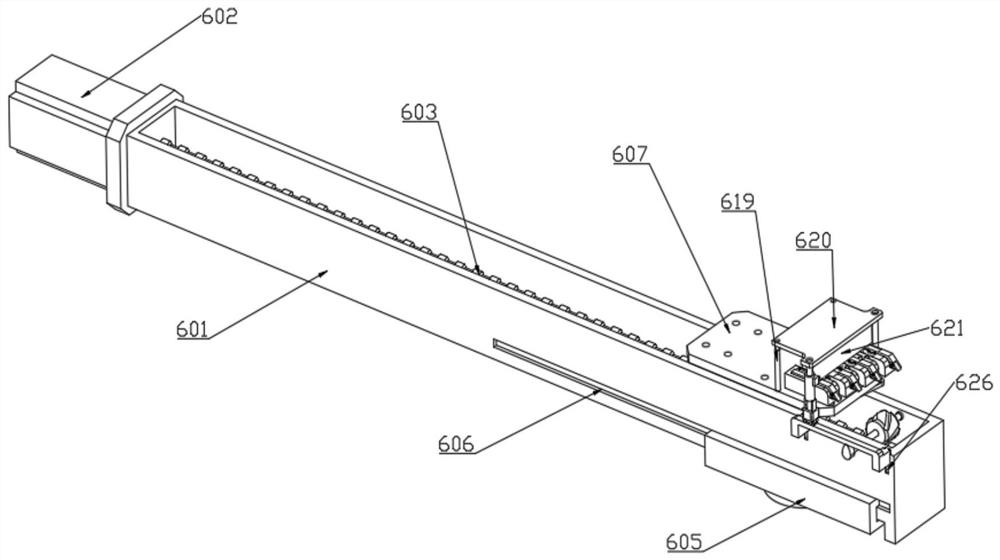

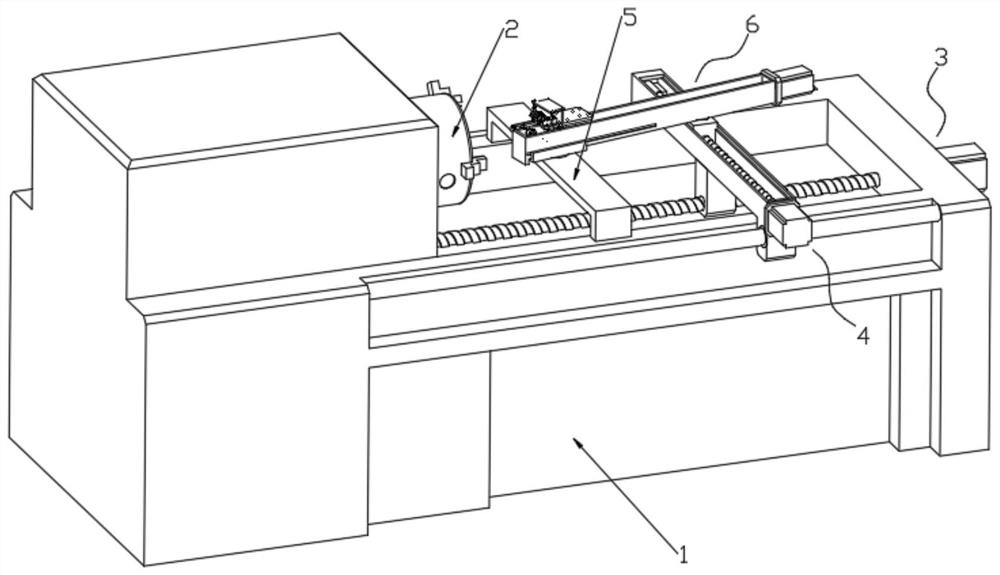

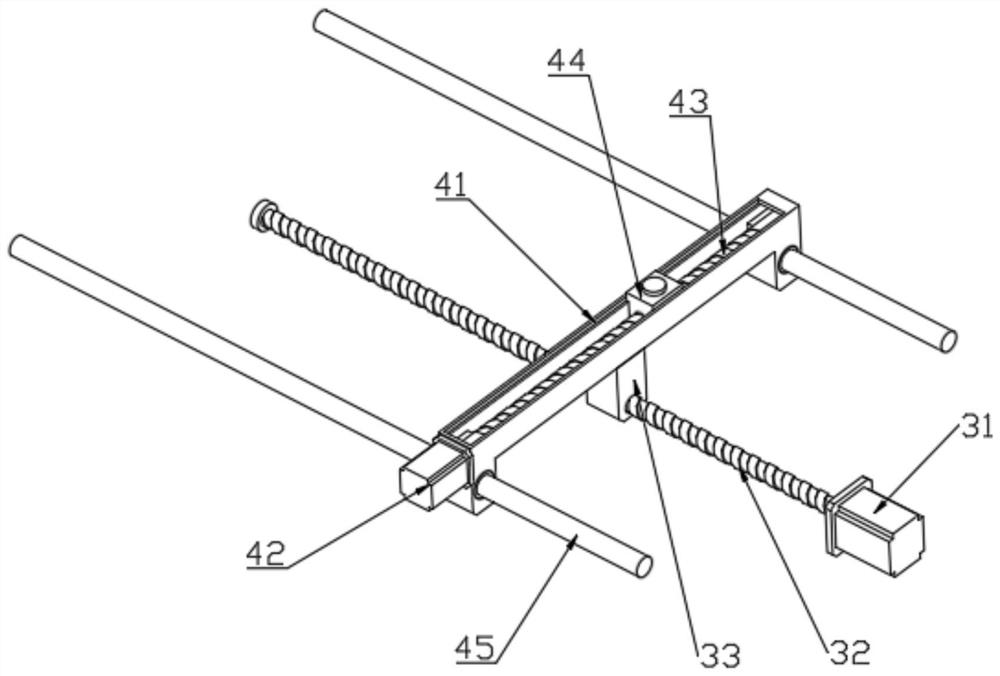

Special machine tool for machining chutes of zigzag labyrinth sealing part

ActiveCN112045199AAvoid mechanical errorsImprove processing efficiencyFeeding apparatusTurning machinesMachineCam

The invention relates to the technical field of machine tool automation equipment, and discloses a special machine tool for machining chutes of a zigzag labyrinth sealing part. The special machine tool comprises a machine body and a chuck, the chuck is installed on the machine body, a first feeding mechanism is installed on the machine body and used for machining axial grooves in a workpiece clamped on the chuck, and a second feeding mechanism is further installed on the machine body and used for machining radial grooves in the workpiece clamped on the chuck. By arranging a third feeding mechanism and adopting a tool arrangement layout manner in the third feeding mechanism, machining of straight grooves, the chutes and the axial grooves can be completed only by clamping the workpiece at atime; the slotting angle can be automatically adjusted according to actual production requirements, and a plurality of turning tools are synchronously fed for slotting, so that the machining efficiency is greatly improved; and by arranging a worm wheel in a second mounting frame and arranging a cam on a rotating shaft, scraps generated in the turning process can be dynamically removed, and it is guaranteed that synchronous cutting of the multiple turning tools is effectively conducted.

Owner:滁州佳庆数控有限责任公司

Composite structure array probe for lath testing and optical fiber white light interference device

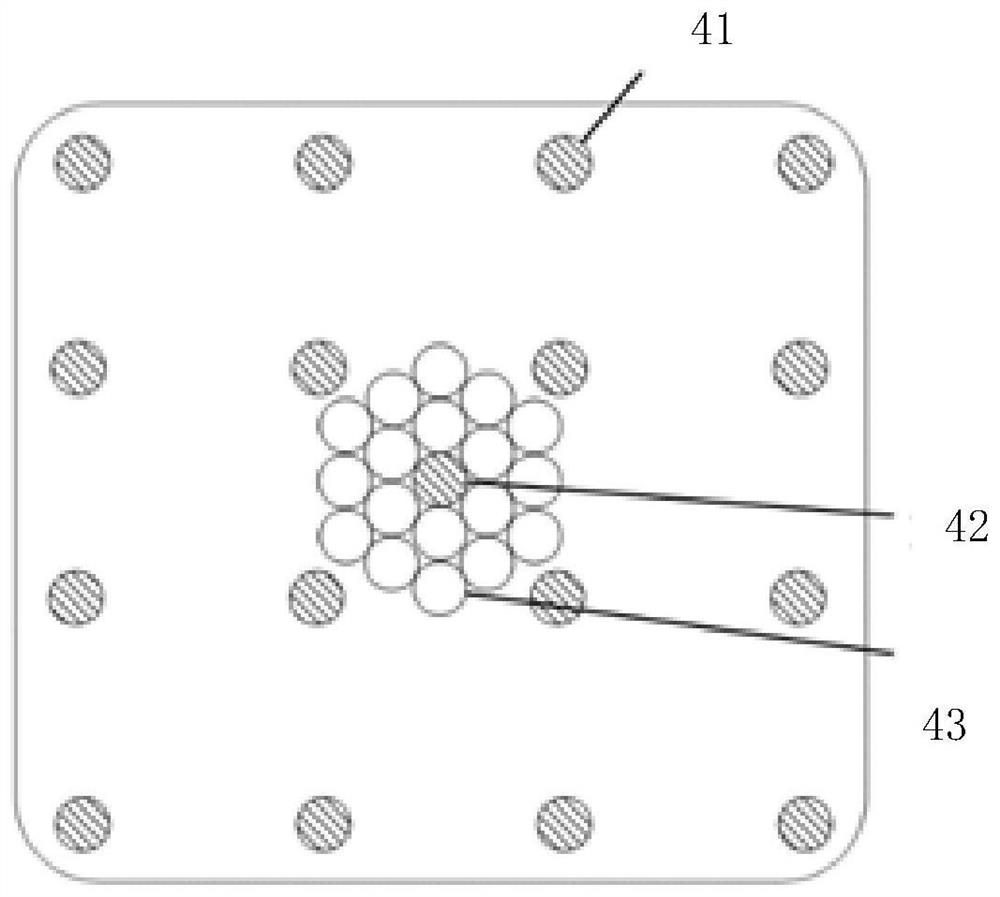

ActiveCN111693545AImprove cross-sectional scanning efficiencyRealize high-precision ultra-large dynamic range detectionPhase-affecting property measurementsOptically investigating flaws/contaminationLight spotDetector array

The invention provides a composite structure array probe for lath testing and an optical fiber white light interference device. The composite structure array probe is composed of measurement probes arranged in a 4*4 manner and a central part alignment probe array, the alignment probe array comprises a transmitting sub-probe and a receiving probe array for reflecting light spots, and the front endof the alignment probe array is provided with a self-focusing lens array for light path alignment. The invention further provides a novel batten detection device matched with the array probe arrangedin the composite structure. The novel batten detection device comprises a light source, a 1*2 coupler 1, an optical switch, a composite array probe, a to-be-detected batten, a displacement adjusting frame, a detector array used for alignment detection, a software driver, a second 2*2 coupler, a Faraday rotator mirror, a delay line structure, an interference signal detection module and an optical element, in the device, an optical element is connected through a single-mode optical fiber, and a software driving part is connected through a circuit to control and receive signals. High-precision ultra-large dynamic range detection of a lath weak reflection area can be realized.

Owner:HARBIN ENG UNIV

Method and device for measuring objects with multiple cameras

The invention relates to a method for measuring an object through multiple cameras and a device thereof. The method comprises the steps that images of different areas of a calibration board photographed by multiple cameras respectively are received; the mapping relation between the pixel coordinate system of each camera and a calibration coordinate system is acquired according to the images of different areas of the calibration board; the images of different areas of an object photographed by the multiple cameras respectively are received, and the pixel coordinates of the images of different areas of the object are acquired; the pixel coordinates of the images of different areas of the object are mapped to the calibration coordinate system according to the mapping relation; and the measurement result of the object is obtained according to the coordinates of the images of different areas of the object in the calibration coordinate system. Therefore, the object or the cameras does / do not need to be rotated or moved so that mechanical error caused by rotation or movement of the cameras can be avoided, and accuracy of the object measurement result can be enhanced.

Owner:HANS LASER TECH IND GRP CO LTD +1

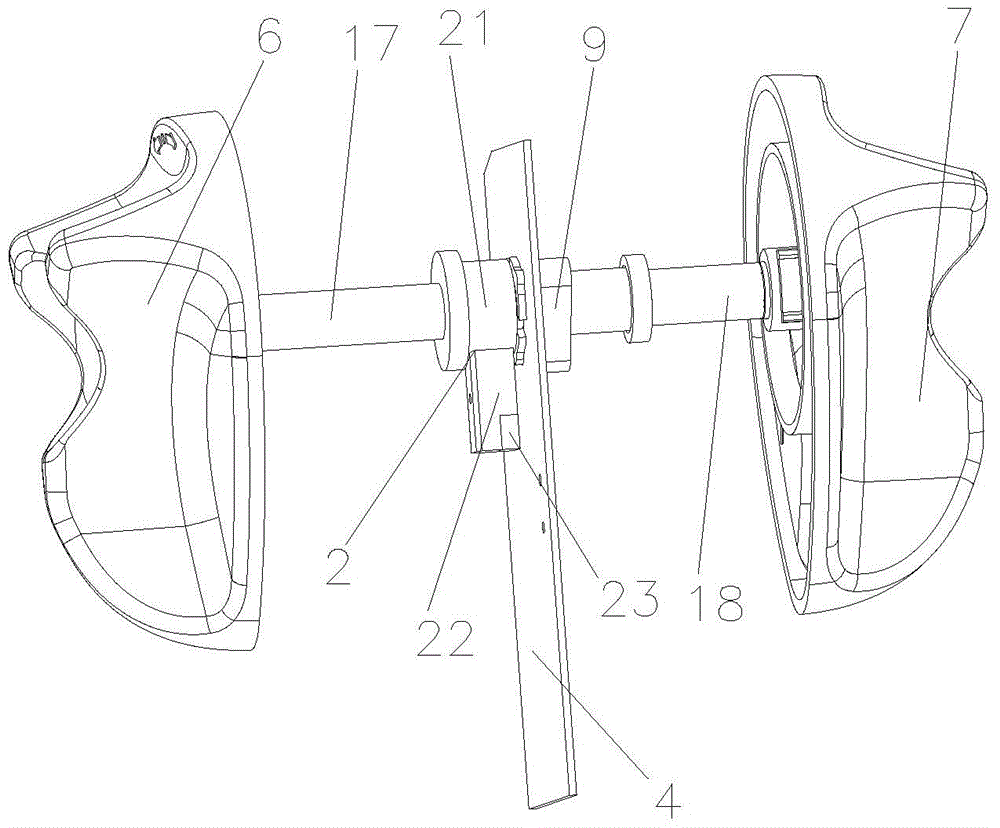

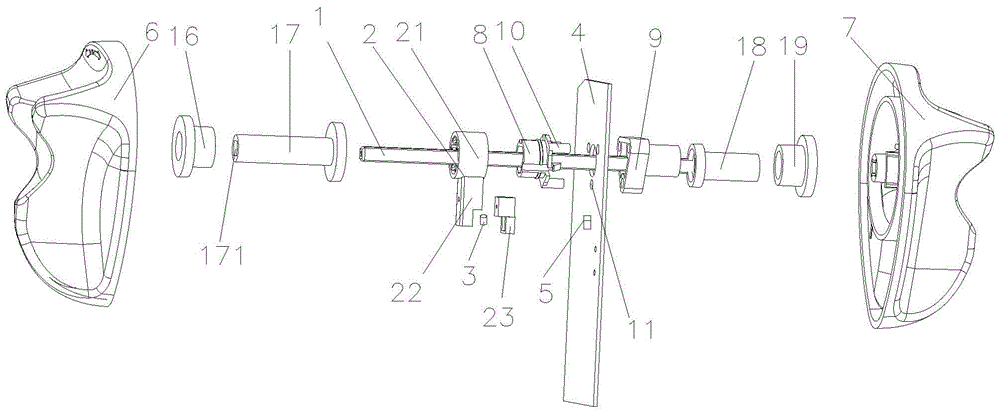

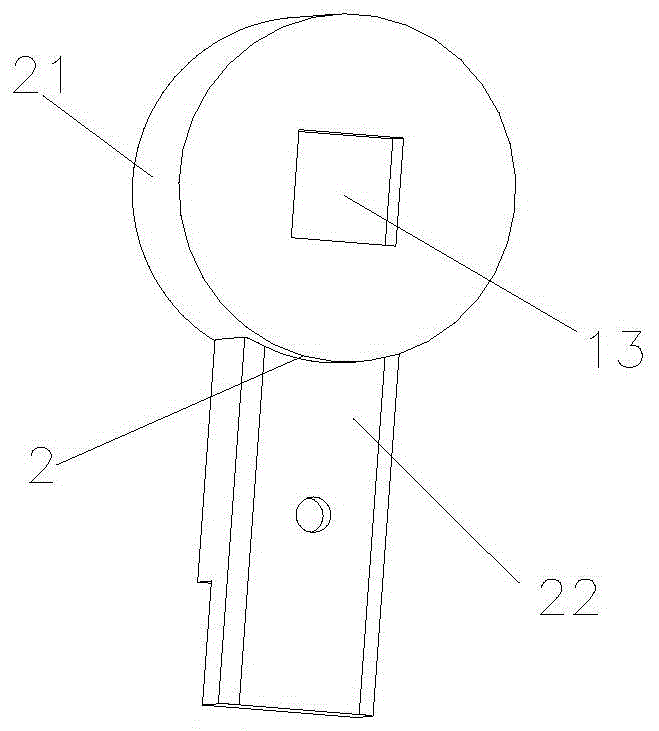

Warehousing forklift accelerator

ActiveCN104553879AAvoid failureAvoid mechanical errorsSpeed controllerElectric energy managementEngineeringControl circuit

The invention relates to a warehousing forklift accelerator, which comprises a rotating handle, a rotary knob rotating shaft, a rotating block, a steel magnet and a PCB (Printed Circuit Board) control circuit board, wherein the rotating handle is arranged at the ends of the rotary knob rotating shaft, the rotating block is fixedly connected with the rotary knob rotating shaft, the steel magnet is arranged at the end of the rotating block, the PCB control circuit board sleeves the rotary knob rotating shaft, a magnet position sensor and a controller are arranged on the PCB control circuit board, the magnet position sensor is connected with the input end of the controller, and the steel magnet is arranged corresponding to the magnet position sensor. The structure of the warehousing forklift accelerator disclosed by the invention is simple, the sensor and a detected object are of a non-contact structure, and thereby failure which is caused by the long-time friction between the sensor and the detected object is prevented; because the warehousing forklift accelerator is provided with a non-gear transmission mechanism, mechanical errors which are caused by mechanical looseness as the result of the abrasion of the transmission mechanism are prevented.

Owner:杭州联核科技有限公司

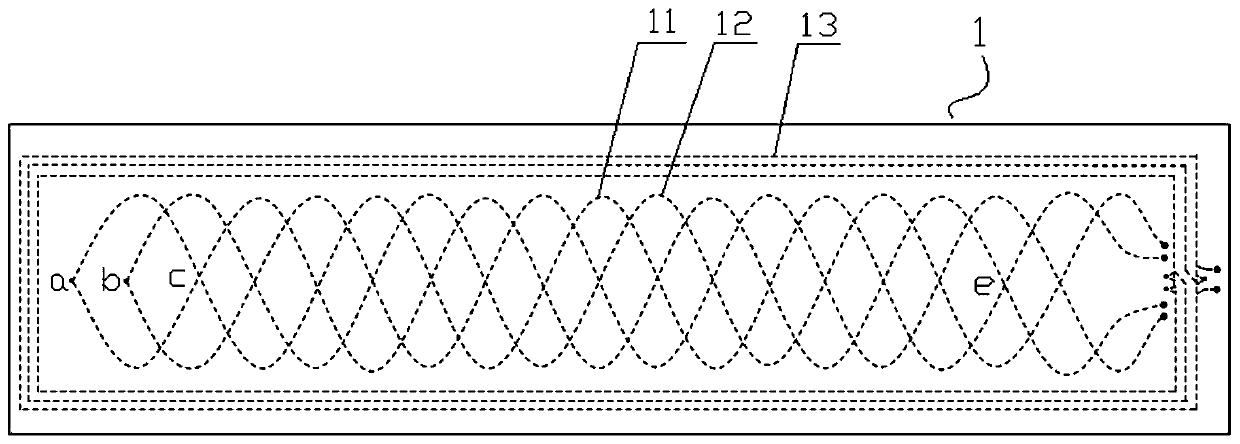

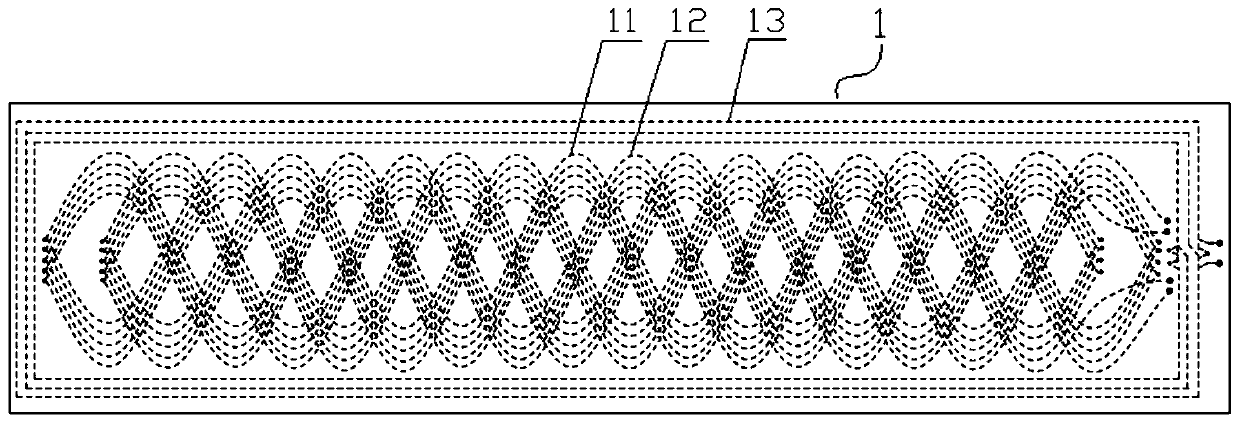

An electromagnetic induction linear displacement sensor

ActiveCN107796293BWork around app limitationsIncrease the induction signalUsing electrical meansConverting sensor output electrically/magneticallyCoil arrayEngineering

The invention discloses an electromagnetic induction type linear displacement sensor, which comprises a fixed length and a moving ruler. The moving ruler is a metal body with rectangular teeth. The printed circuit board of the coil line array, the second coil line array and the plane rectangular spiral coil group, the first coil line array and the second coil line array are composed of the first and second sinusoidal coils, and the plane rectangular spiral coil group consists of four The same planar rectangular spiral coils are connected in series. The first and second coil arrays are fed with two-phase orthogonal alternating excitation signals or the planar rectangular spiral coil is fed with one-phase alternating excitation signals, and an alternating magnetic field will be generated on the surface of the fixed scale. When the moving scale moves relative to the fixed scale , the planar rectangular spiral coil or the first and second coil arrays will generate an induction signal that has a specific functional relationship with the displacement of the moving scale, and the corresponding displacement can be obtained after calculation. The invention is suitable for being integrated with application objects, can avoid installation errors and improve measurement accuracy.

Owner:CHONGQING UNIV OF TECH

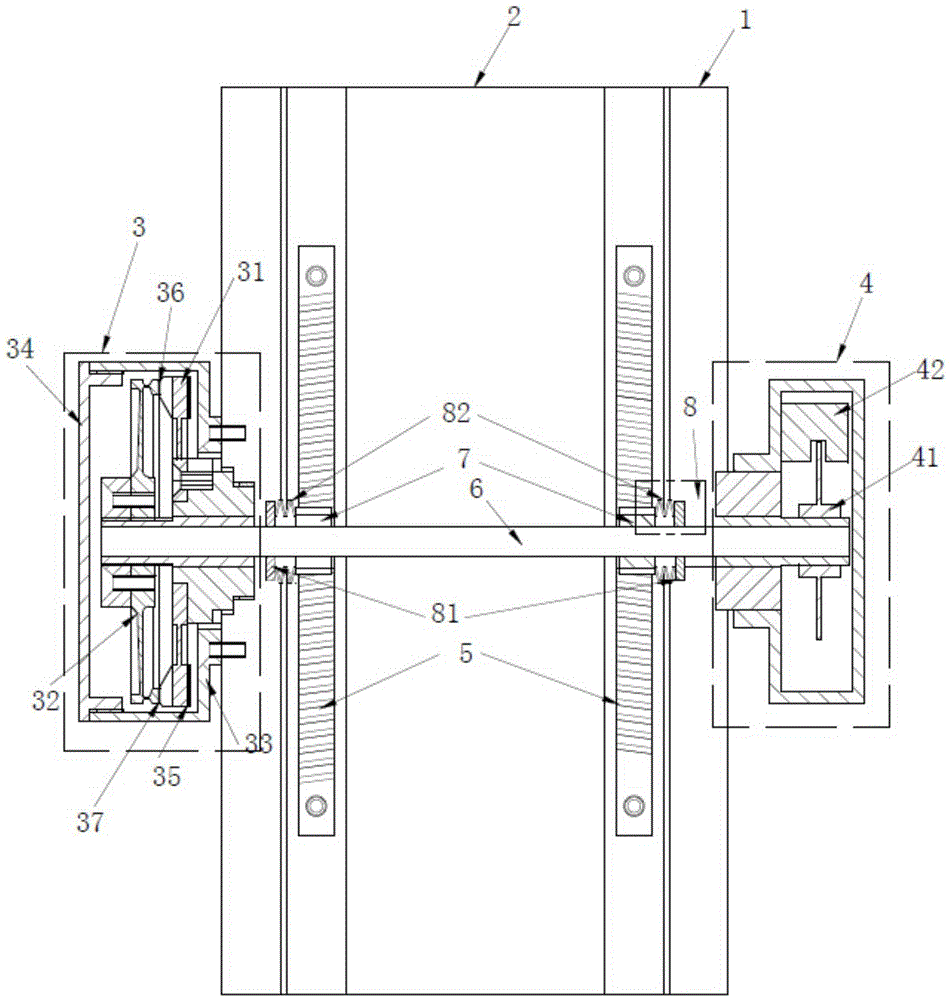

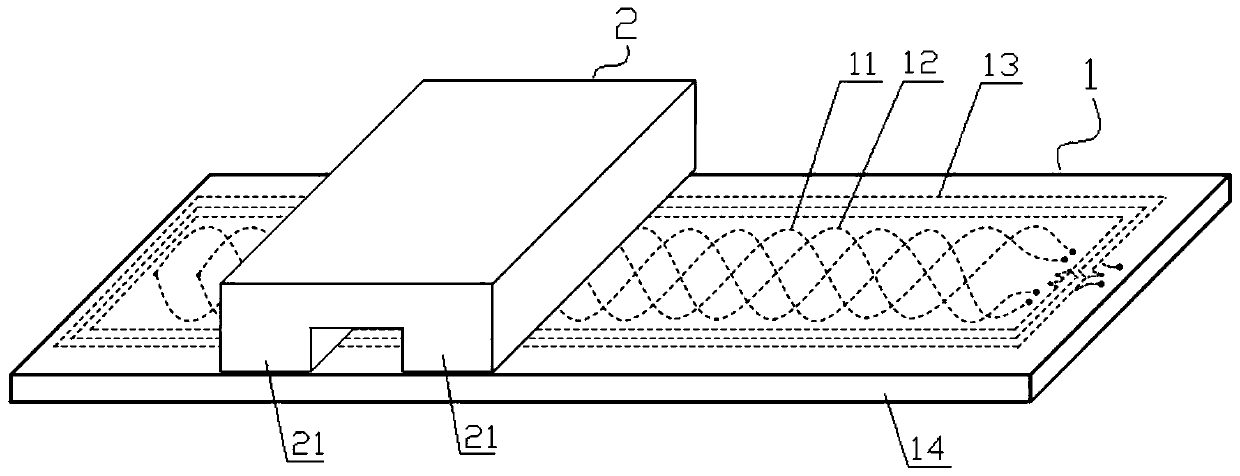

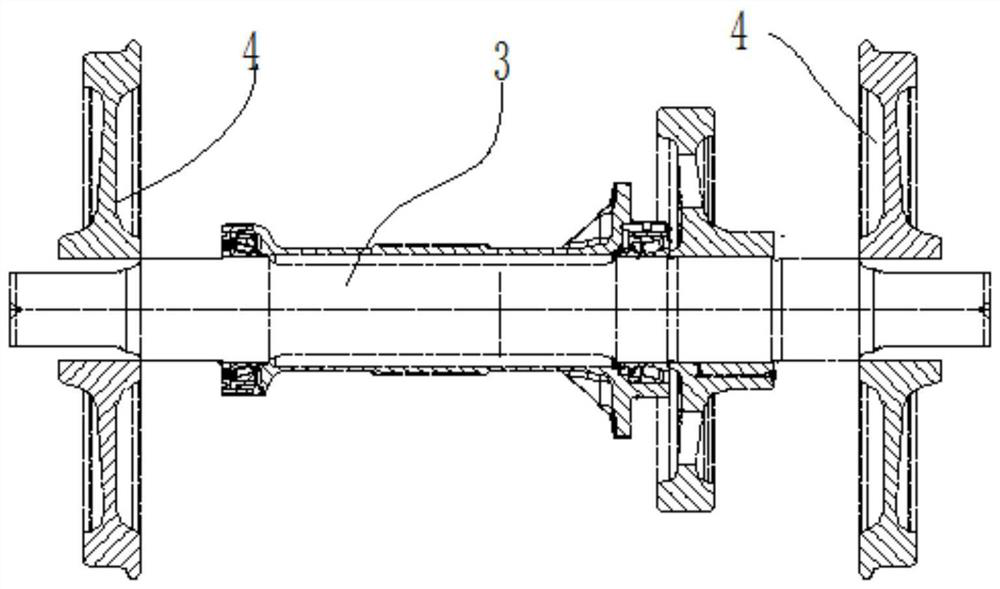

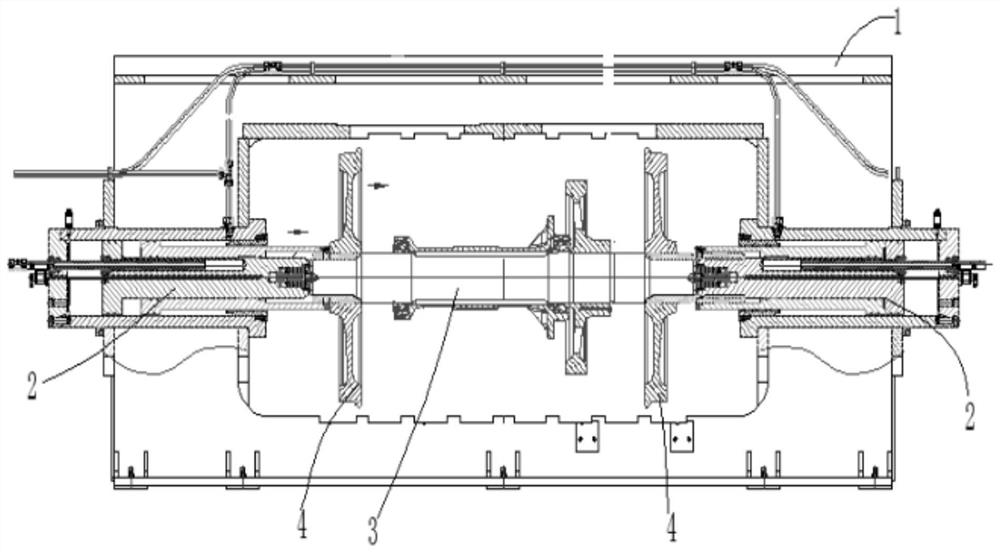

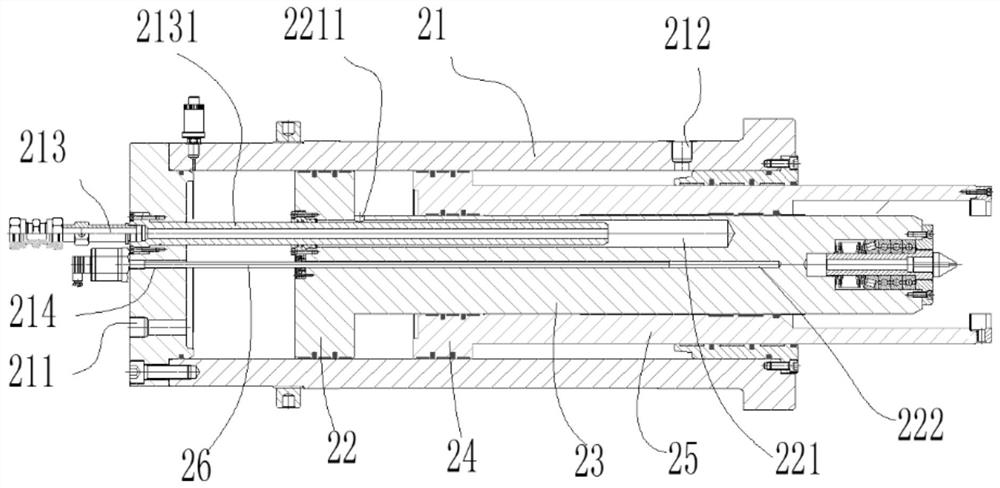

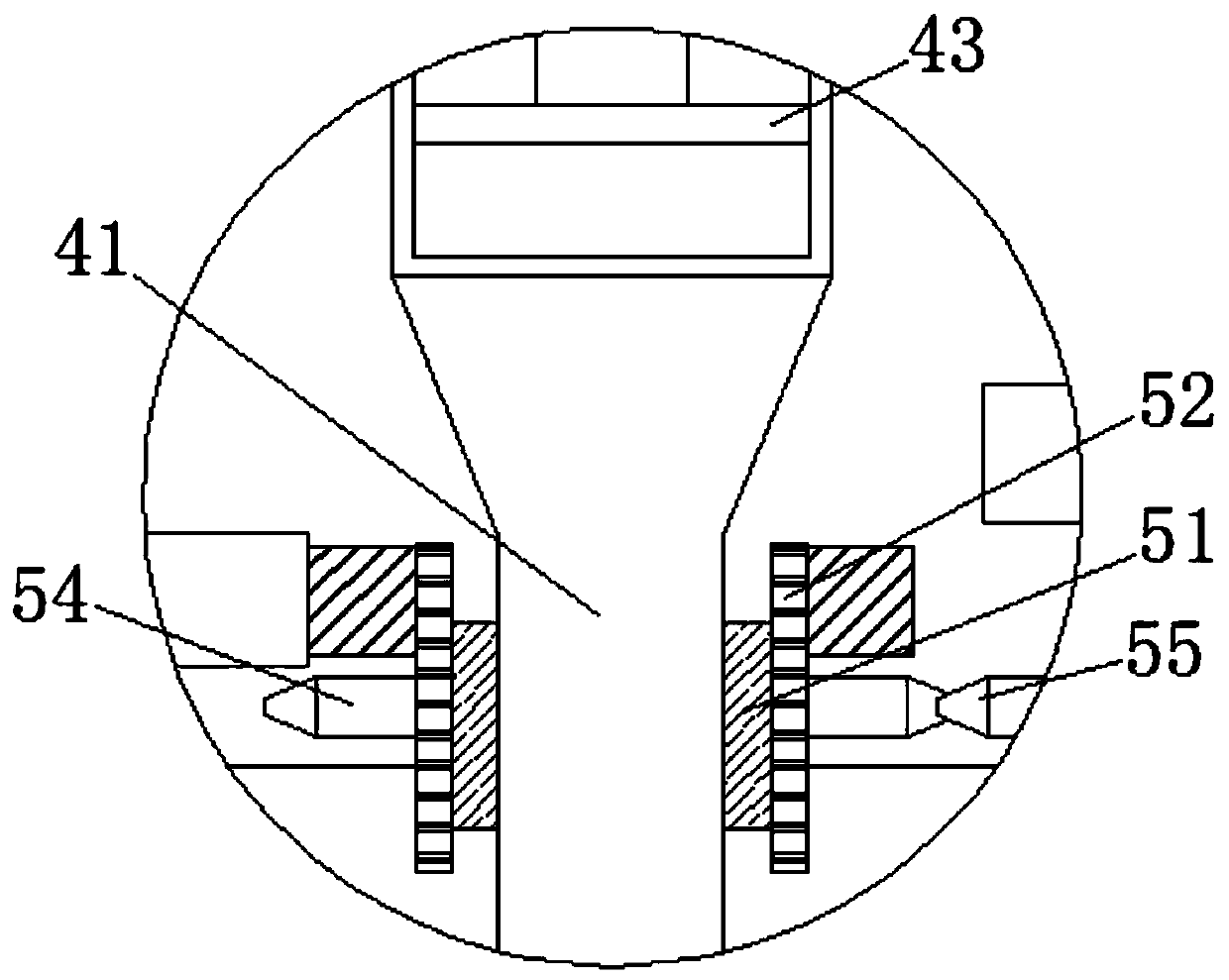

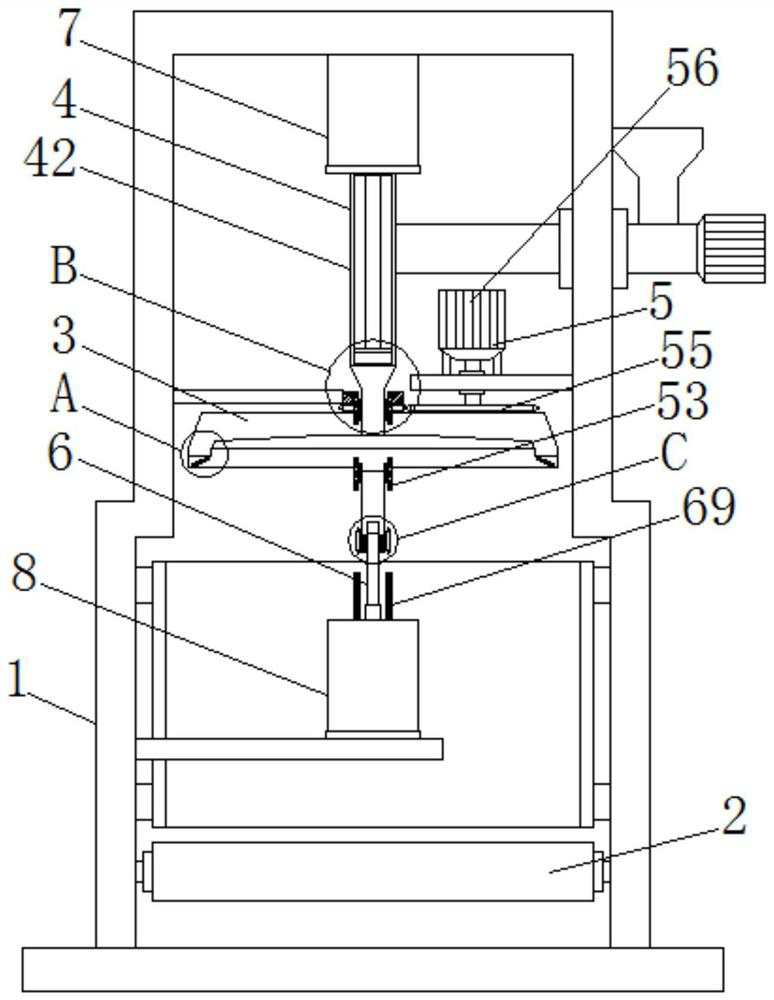

Wheel set press-fitting machine and wheel set press-fitting method

InactiveCN113020951AAvoid mechanical errorsHigh precisionMetal working apparatusWheel and axleControl engineering

The invention discloses a wheel set press-fitting machine and a wheel set press-fitting method. The wheel set press-fitting machine comprises a rack, two press-fitting mechanisms and a controller, wherein the press-fitting mechanisms are electrically connected with the controller, and the two press-fitting mechanisms are distributed in a spaced mode in the left-right direction and horizontally and fixedly installed at the left end and the right end of the rack correspondingly. The press-fitting mechanisms are used for clamping the two ends of an axle wherein a wheel set is to be installed in a press fitting mode, and conducting press-fitting on wheels pre-assembled at the two ends of the axle in place. Each press-fitting mechanism further comprises a displacement sensor, and the displacement sensors are used for detecting the extending lengths of the press-fitting mechanisms when the press-fitting mechanisms clamp the axle. The controller controls the extension lengths of the two press-fitting mechanisms according to the detection results of the two displacement sensors when the two press-fitting mechanisms clamp the axle, so that the axle can be centered in the rack, and the controller further controls the press-fitting mechanisms to carry out press-fitting on the wheels. The wheel set press-fitting machine achieves convenient installation, and a small installation error and is low in rework rate.

Owner:BEIJING SHEENLINE GRP CO LTD

Radiotherapy equipment, treatment target and manufacturing method thereof, radiotherapy method

ActiveCN104474639BExtended propagation distanceShorten the propagation distanceRadiation diagnosticsTherapeutic AreaRadiation treatment planning

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Storage forklift acceleration device

ActiveCN104553879BSimple mechanical structureEasy maintenanceSpeed controllerElectric energy managementEngineeringControl circuit

Owner:杭州联核科技有限公司

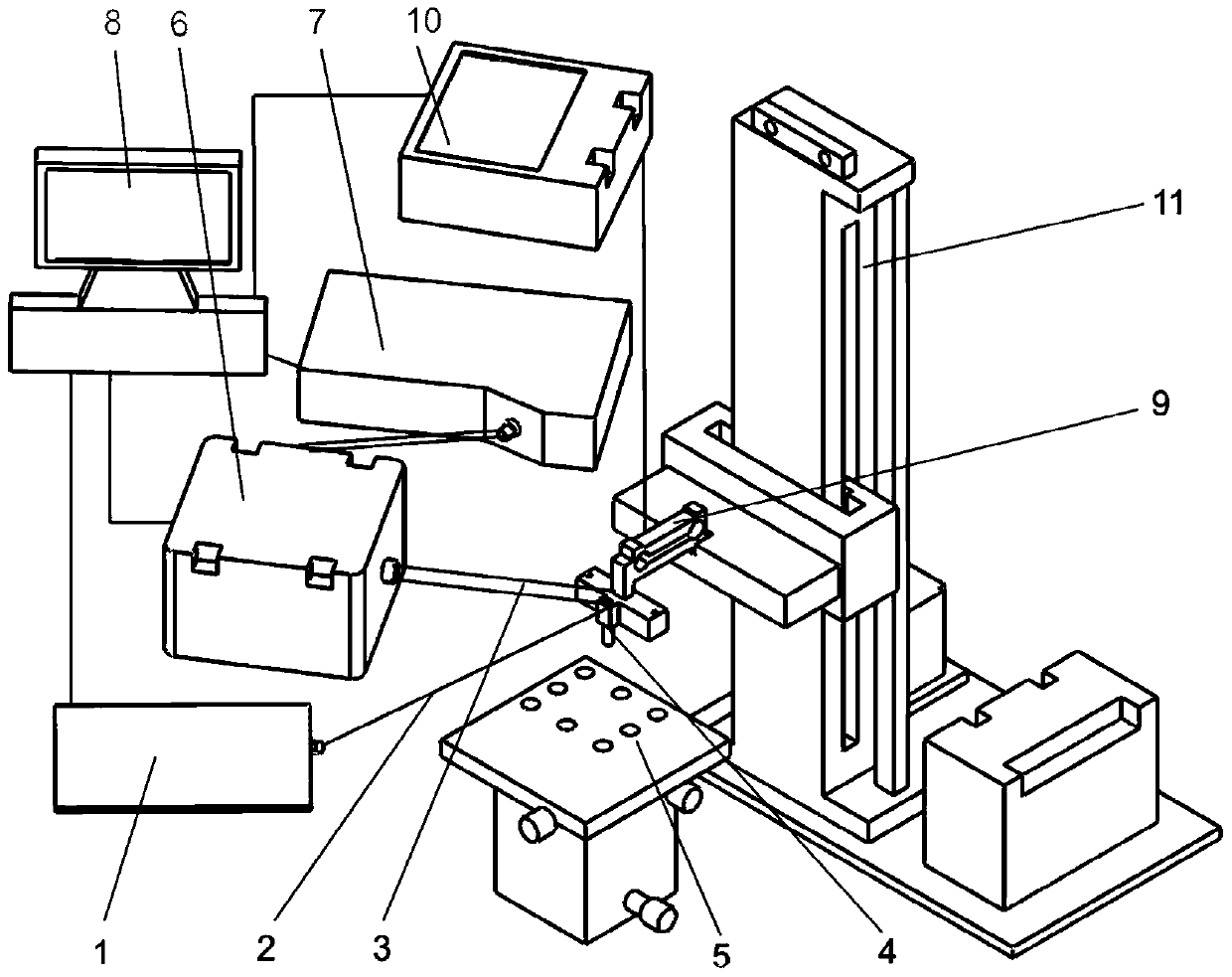

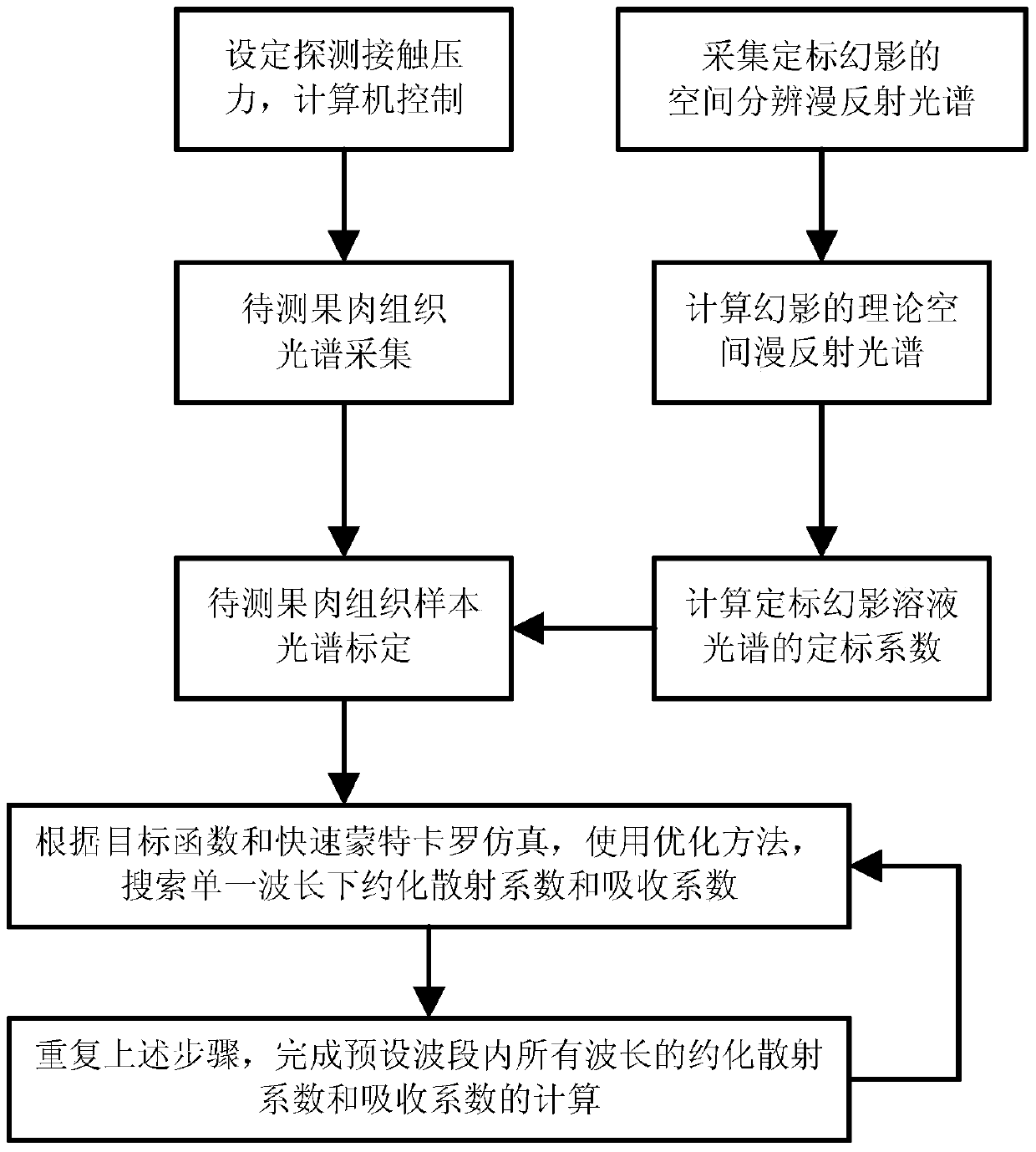

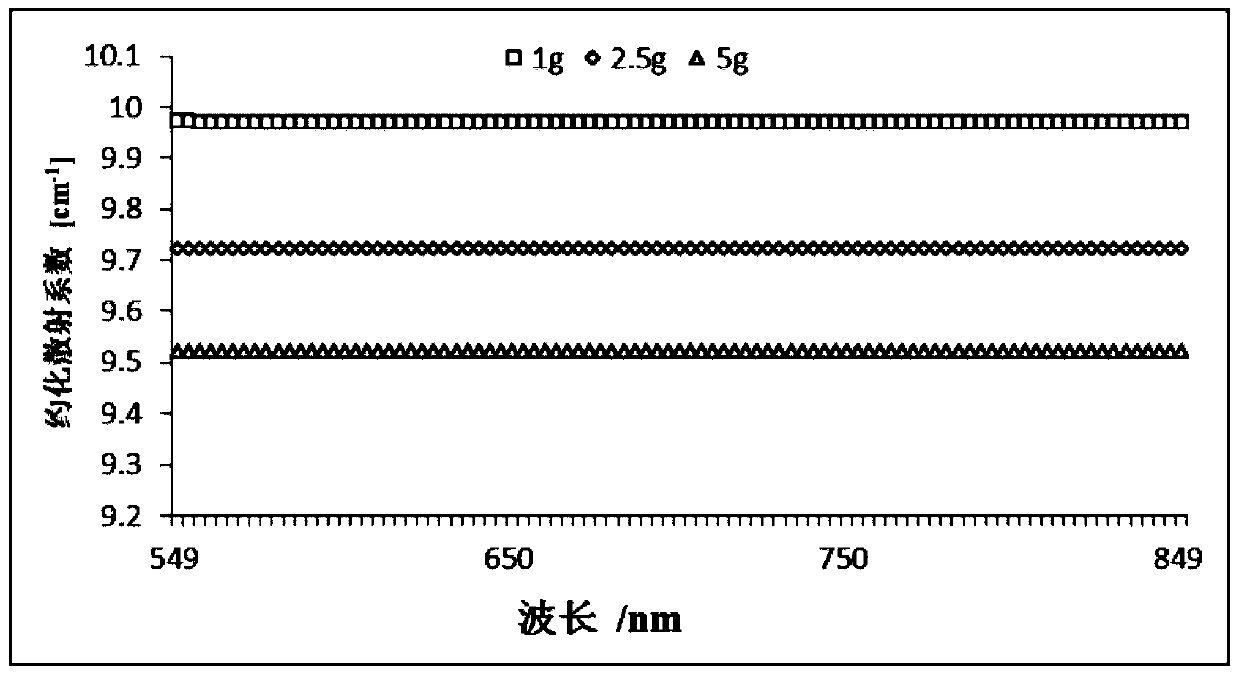

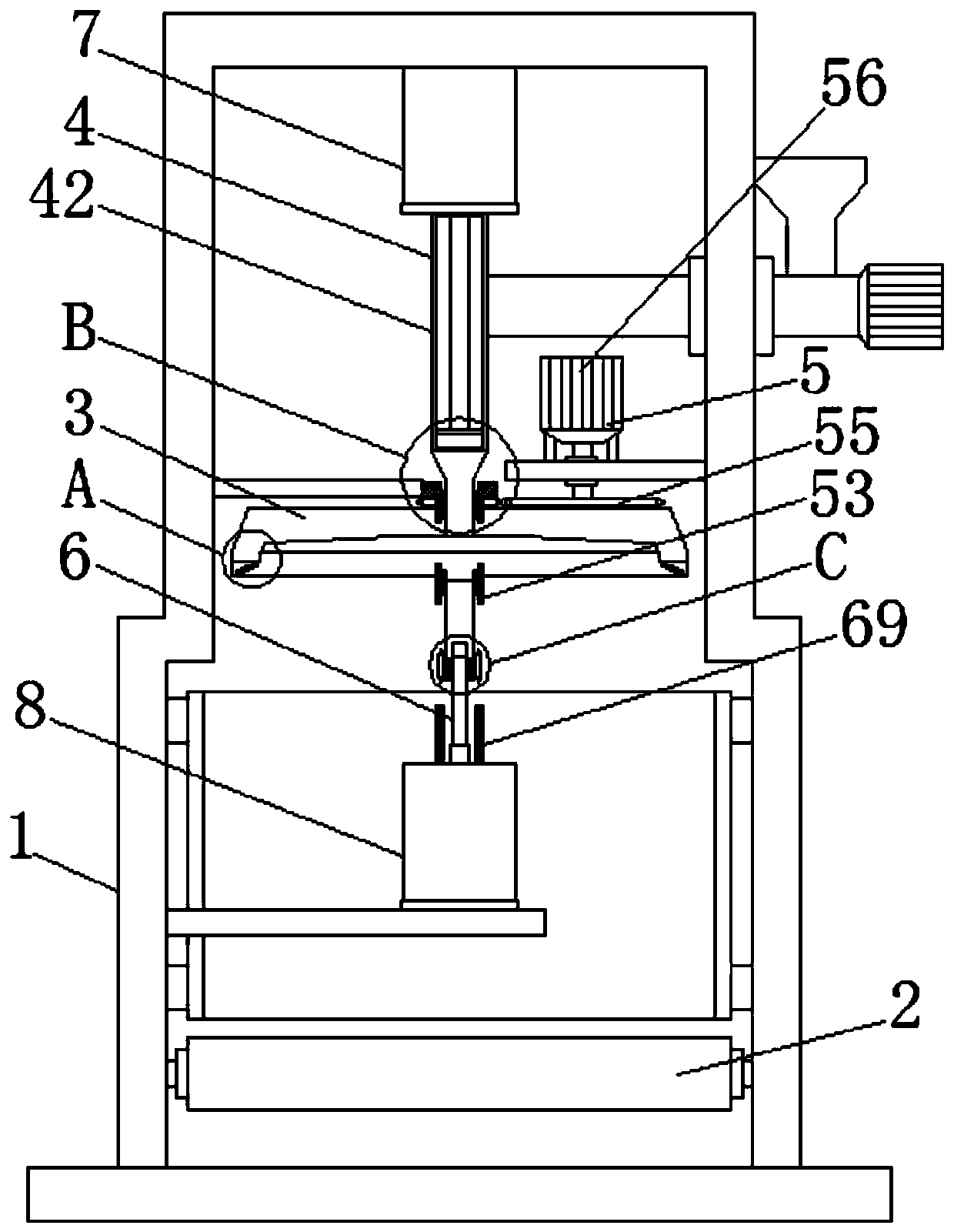

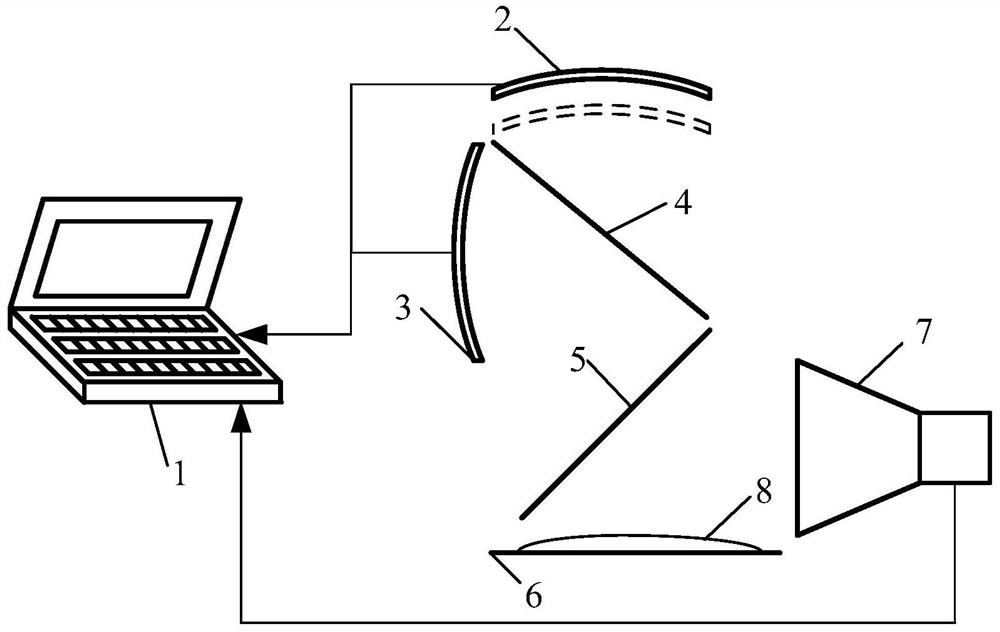

System and method for detecting optical characteristics of fruit pulp tissue with integrated optical fiber probe

ActiveCN105424653BEasy to controlAvoid mechanical errorsScattering properties measurementsFiberReflectance spectroscopy

The invention discloses a fruit pulp tissue optical property detection system and method adopting an integrated fiber-optics probe. The system comprises a tungsten halogen light source, illumination optical fiber, receiving optical fiber, the probe, an objective table, a switcher, a spectrograph, a computer, a pressure sensor, a pressure displayer and a vertical slide table. A calibration ghost solution is prepared, the actual space resolved diffuse reflection spectrum is obtained, the theoretical space resolved diffuse reflection spectrum is obtained through calculation, the final calibration coefficients, corresponding to different wavelength points, of all the receiving optical fiber are obtained through calculation, spectrum detection and spectrum calibration are conducted on a fruit pulp tissue sample to be detected, the predicted value of the space diffuse reflection spectrum is calculated, the measured value is extracted, and the predicted values of the reduced scattering coefficient and the absorption coefficient under different wavelengths are obtained through searching and calculation of an objective function value with the simplex optimization method. According to the system and method, environmental constraints existing in other methods are avoided, the adaptation range of a detection object is widened, the detection speed is increased, the calibration error is reduced, and online detection application prospects are broad.

Owner:ZHEJIANG UNIV

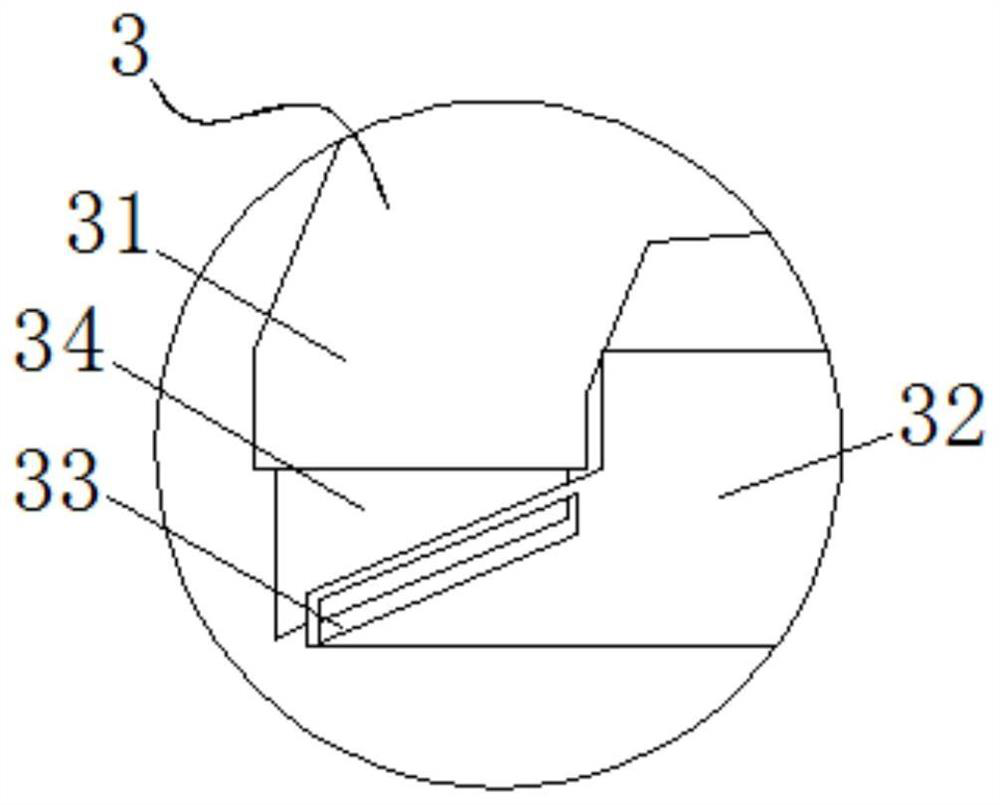

Molding device for dumpling wrappers

ActiveCN110074153AImprove yieldAvoid mechanical errorsDough processingDisc dough shapingEngineeringCentrifugal force

The invention relates to the technical field of processing equipment of dumpling wrappers and discloses a molding device for dumpling wrappers. The molding device comprises a frame and a belt conveyorarranged on the lower part of an inner chamber of the frame; the molding device for dumpling wrappers further comprises a spinning molding component, a feeding component, a driving source and a discharging component; the spinning molding component is arranged in the frame and is used for molding the dumpling wrappers; the feeding component is arranged on an upper end face of the spinning moldingcomponent; the driving source is arranged on the frame and is used for supplying power to the spinning molding component; the discharging component is arranged on a lower end face of the spinning molding component. In the process of molding the dumpling wrappers, the molding device is capable of automatically filling dough into the whole inner chamber of the molding groove under an effect of centrifugal force, so that the mechanical error of the traditional mechanical grinding is avoided and the yield of dumpling wrapper processing is higher.

Owner:新沂市棋盘工业集中区建设发展有限公司

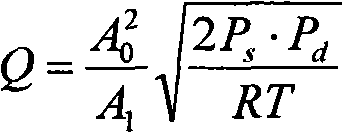

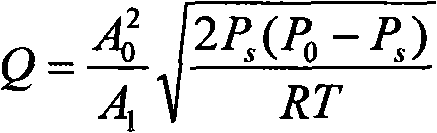

Method for measuring nozzle flow characteristic of inert gas fire-extinguishing system

InactiveCN101726338BSimplify the measurement procedureReduced measurement timeIndirect mass flowmetersEngineeringDynamic pressure

The invention relates to a method for measuring the flow characteristic of a nozzle of an inert gas fire-extinguishing system. The method comprises the following steps: (1) arranging a static pressure, dynamic pressure or total pressure sensor and a temperature sensor on the same section of the upstream pipe of the nozzle to measure the static pressure, dynamic pressure or total pressure and the temperature; (2) measuring and calculating the sectional area of the pipe and the area of the nozzle exit at the pressure-measuring point; (3) substituting the measured static pressure, dynamic pressure or total pressure, the temperature, the sectional area of the pipe and the area of the nozzle exit into the flow calculation formula of the extrusive gas of the nozzle to calculate the Q value; (4) substituting the flow Q value into the spraying rate calculation formula to calculate the phi value; and (5) adopting the spraying rates of the nozzle at different spraying static pressures to draw a flow characteristic curve through a data processing method. By using the method of the invention, the measuring device and measuring procedure of the flow characteristic of the nozzle in the inert gas fire-extinguishing system are simplified, the measuring time is shortened, the work efficiency of the measurement is increased, the mechanical error generated in the measuring process is avoided, and the measuring precision is increased.

Owner:TIANJIN FIRE RES INST

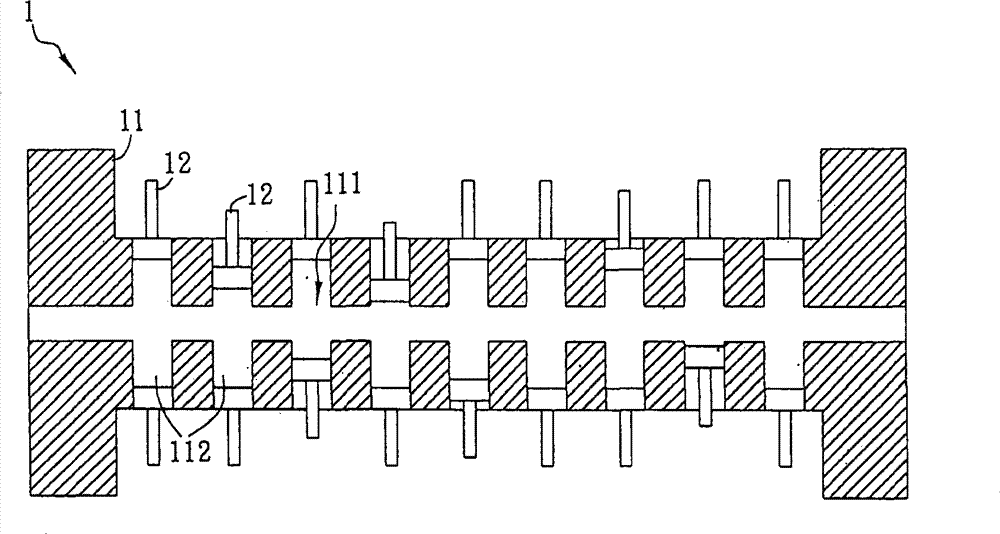

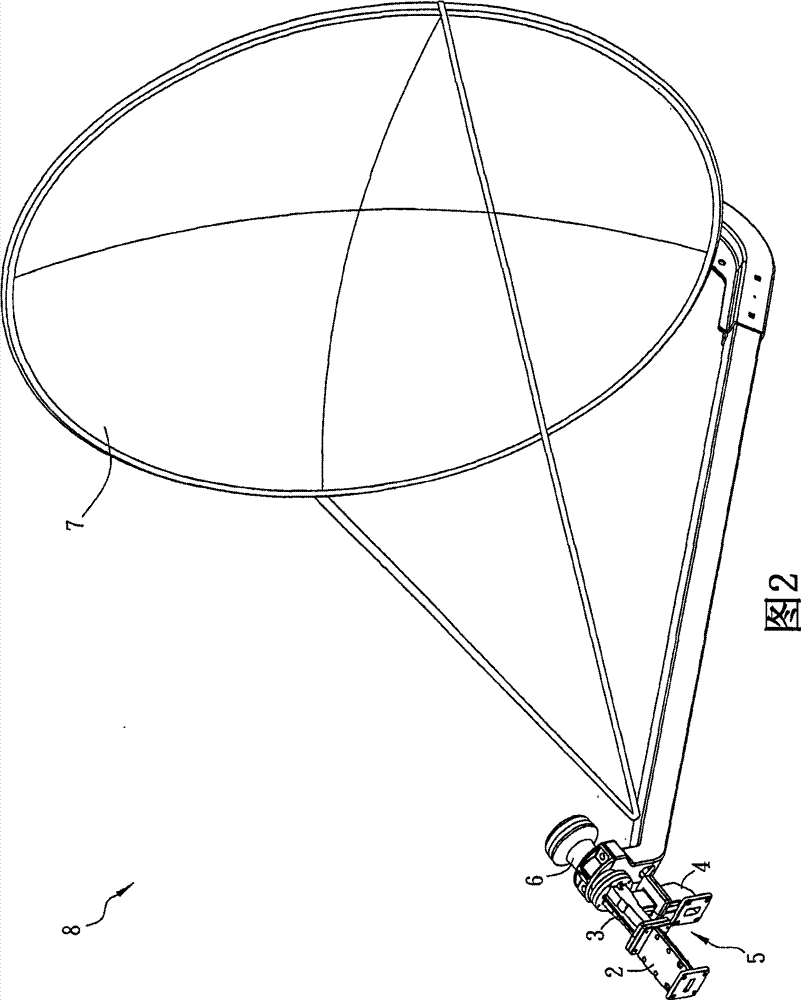

Satellite antenna equipment, transceiver module and filter unit

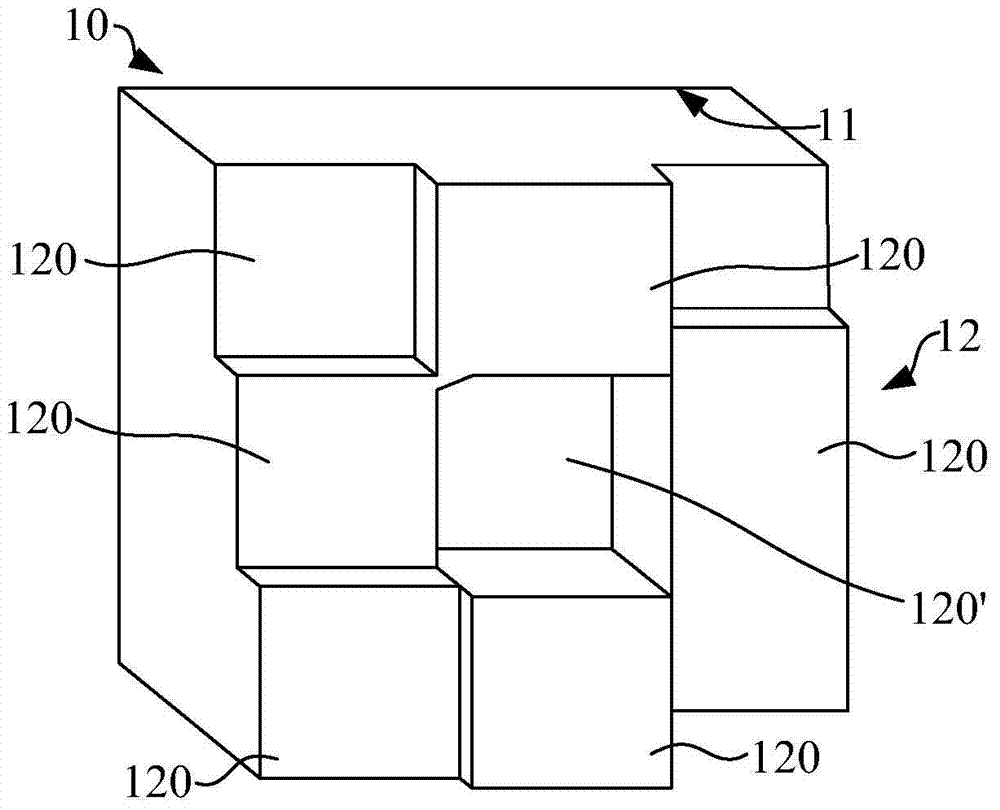

InactiveCN101673862BImprove filtering effectAvoid Adjustment ErrorsWaveguide type devicesAntennasTransceiverEngineering

The invention relates to a filter unit comprising a filter base and a cover body. The filter base is provided with a plurality of first filter slots arranged at intervals; the cover body and the filter base are jointed to form a filter space, and the filter base is provided with a plurality of second filter slots which are arranged at intervals and correspond to the first filter slots, wherein the materials of the filter base and the cover body contain zinc-aluminium alloy. The invention also discloses satellite antenna equipment using the filter unit and a transceiver module thereof.

Owner:AZURE SHINE INT

A kind of dumpling skin forming equipment

ActiveCN110074153BImprove yieldAvoid mechanical errorsDisc dough shapingDough processingEngineeringCentrifugal force

Owner:新沂市棋盘工业集中区建设发展有限公司

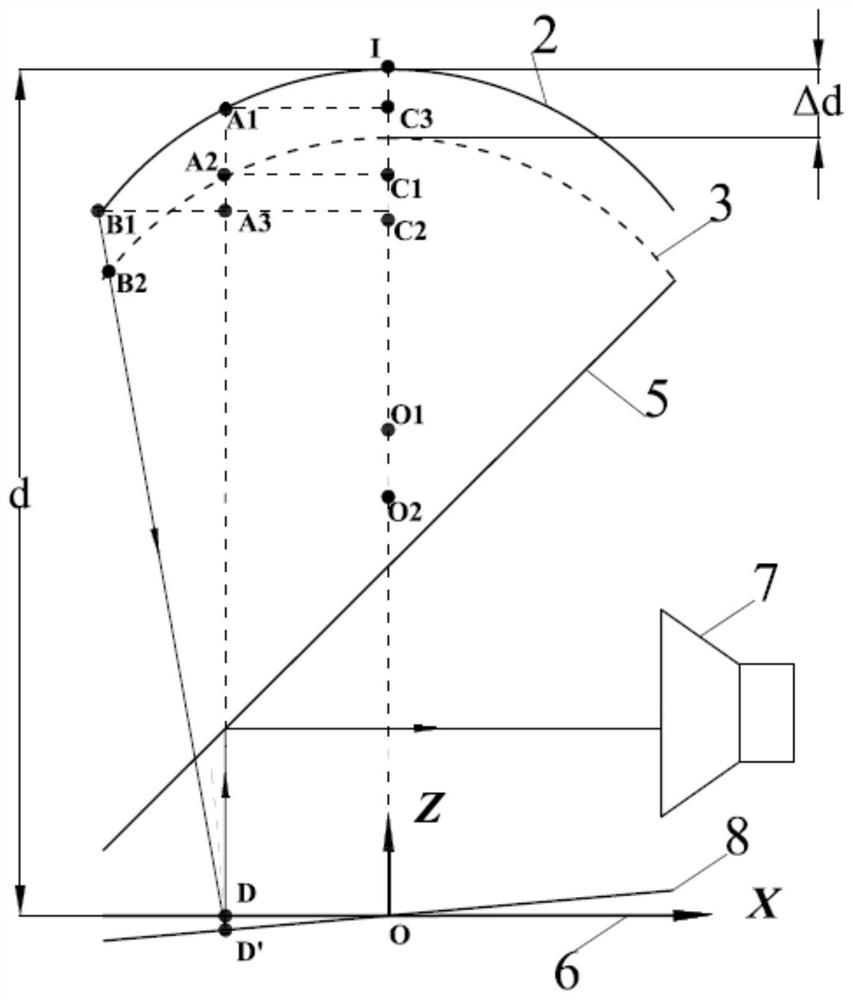

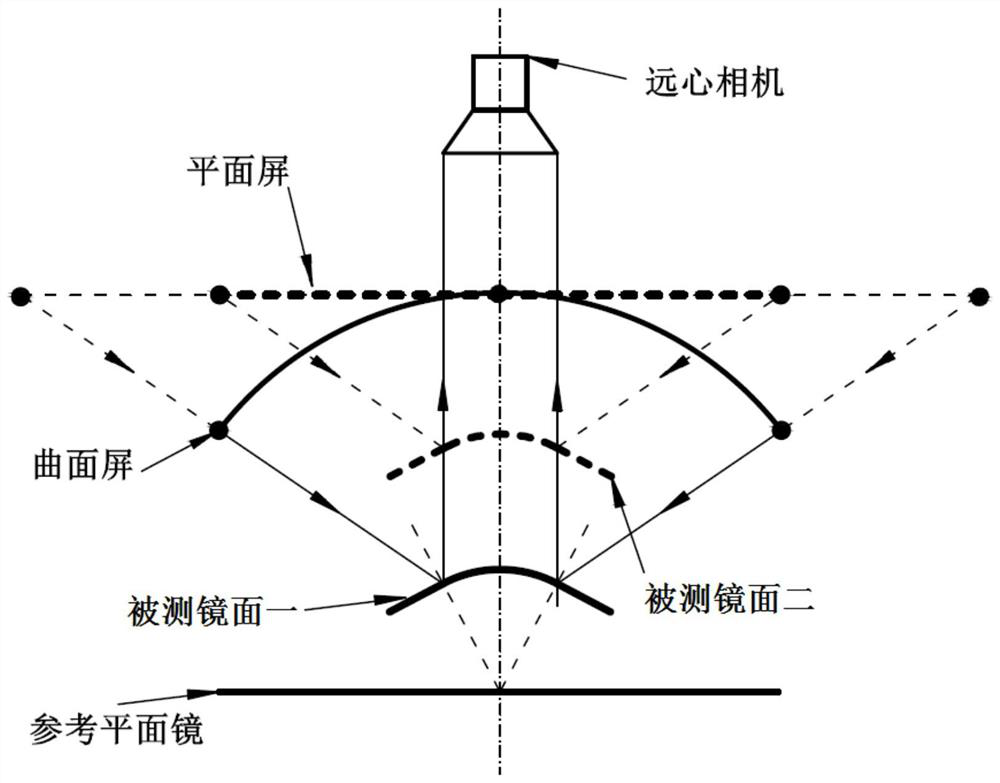

Three-dimensional shape measurement method of large curvature mirror based on phase deflection of curved screen

ActiveCN113280755BEasy to handleImplement depth measurementUsing optical meansPlane mirrorMirror plane

Owner:HEBEI UNIV OF TECH

A special machine tool for machining inclined grooves of zigzag labyrinth seal components

ActiveCN112045199BAvoid mechanical errorsImprove processing efficiencyFeeding apparatusTurning machinesMachineCam

The invention relates to the technical field of machine tool automation equipment, and discloses a special machine tool for machining chutes of a zigzag labyrinth sealing part. The special machine tool comprises a machine body and a chuck, the chuck is installed on the machine body, a first feeding mechanism is installed on the machine body and used for machining axial grooves in a workpiece clamped on the chuck, and a second feeding mechanism is further installed on the machine body and used for machining radial grooves in the workpiece clamped on the chuck. By arranging a third feeding mechanism and adopting a tool arrangement layout manner in the third feeding mechanism, machining of straight grooves, the chutes and the axial grooves can be completed only by clamping the workpiece at atime; the slotting angle can be automatically adjusted according to actual production requirements, and a plurality of turning tools are synchronously fed for slotting, so that the machining efficiency is greatly improved; and by arranging a worm wheel in a second mounting frame and arranging a cam on a rotating shaft, scraps generated in the turning process can be dynamically removed, and it is guaranteed that synchronous cutting of the multiple turning tools is effectively conducted.

Owner:滁州佳庆数控有限责任公司

Active-passive joint-arm type measuring robot

InactiveCN100519099CCompensation accuracyMake up for the deficiency of only passive data collectionMeasurement devicesManipulatorControl theoryPassive joint

The invention relates to an active and passive articulated arm type measuring robot, which comprises sequentially connected I-axis assemblies, II-axis assemblies, III-axis assemblies, IV-axis assemblies and V-axis assemblies; The transmission device and active-passive switching device, the encoders for measuring the output rotation angle of each shaft are directly connected to the output shafts of each shaft assembly, or indirectly connected to the output shafts of each shaft assembly through corresponding geometric relationships. The invention combines the advantages of the traditional three-coordinate measuring machine and the existing passive articulated arm measuring machine, and at the same time makes up for the accuracy problem of the traditional industrial robot and the deficiency that the passive articulated arm measuring arm can only passively collect data. The measurement accuracy is high, and at the same time, it can also actively carry out trajectory planning. The encoder can collect the final motion angle of each joint axis, thereby avoiding the step loss of the stepping motor and the mechanical error between the components of the harmonic reducer. The invention can be widely used in the measurement or inspection process of various products.

Owner:廊坊智通机器人系统有限公司

Single-point weight metering system, weighing device and weighing method

PendingCN110440881AReduce the effect of temperatureImprove thermal stabilityWeighing apparatus using elastically-deformable membersElastomerDevice form

The invention relates to the technical field of weight metering, and discloses a single-point weight metering system. The system comprises an elastomer and an object deformation telemetering system, wherein the elastomer is made of a low-thermal expansion coefficient material; the elastomer has a fixed mounting position, a weighing position and a displacement deformation position; the elastomer isrigidly connected with the outer part through the mounting position; a tested object applies force on the weighing position of the elastomer; the object deformation telemetering system comprises a monitoring assembly and a monitored device; the monitored device is connected with the displacement deformation position of the elastomer; the monitoring end of the monitoring assembly faces the monitored device; and after the elastomer suffers the force applied by the tested object, the position of the displacement deformation position is changed to ensure that the displacement distance of the monitored device is detected through the monitoring assembly so as to calculate the weight of the tested object. The invention further discloses a weighing device formed by adoption of the single-point weight metering system on the basis of multiple deformations of the single-point weight metering system and a corresponding weighing method.

Owner:徐明远

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com