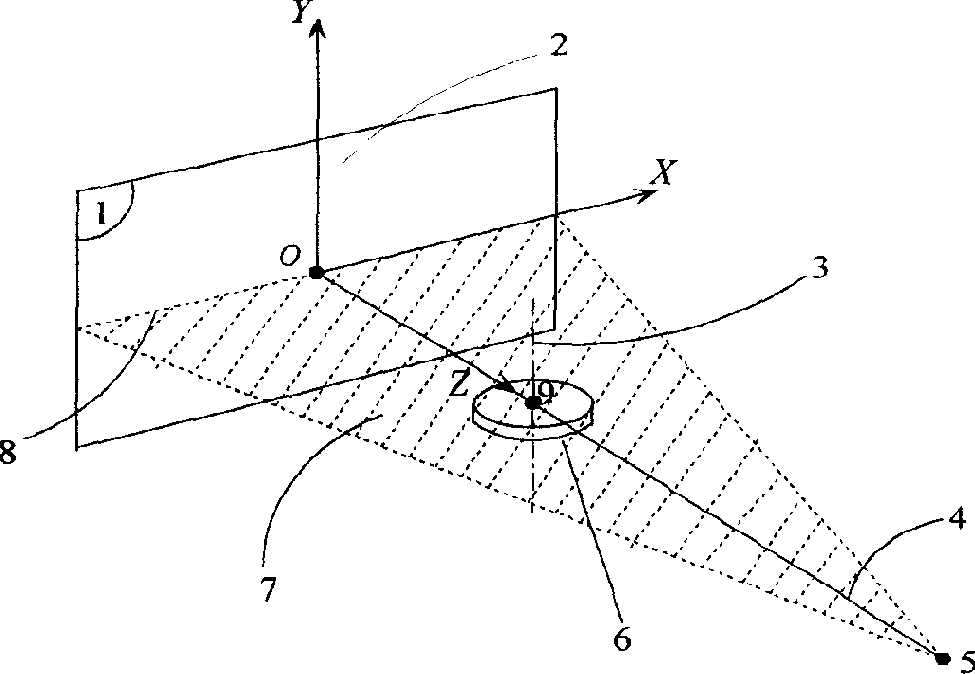

Scale template used for pyramidal tract x-rays CT system

An X-ray, calibration technology, applied in the field of medical imaging technology or non-destructive testing, can solve the problems of multivariate falling into local optimal solution, mechanical error and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

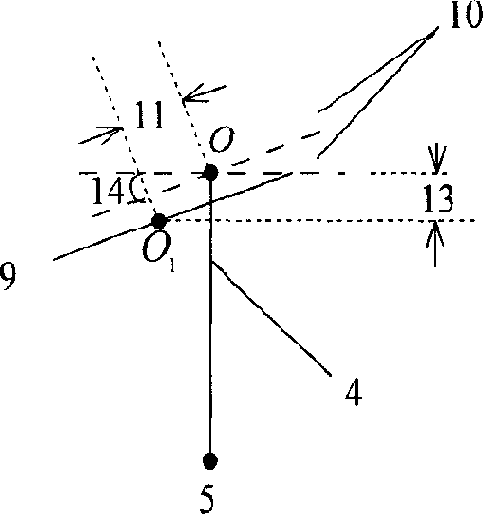

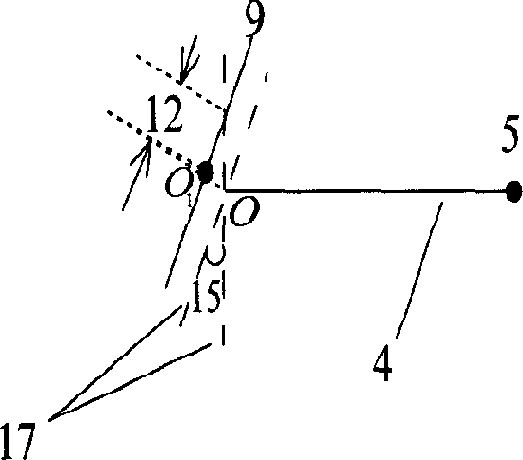

[0137] The first step is to adjust the rotary platform to the level with a level, and then collect the projection data of the calibration template at a certain rotation angle position. There are two ways to make the calibration template, one is to inlay four point-shaped metal balls on the plexiglass plate, and the four metal balls are respectively located on the four vertices of the square; the other is to drill four points on the metal plate. The four holes are located on the four vertices of the square. The inventor needs to accurately measure the side length of the square on the calibration template (that is, the hole distance). According to the magnification of the ideal imaging relationship, the side length of the projection square of the template on the ideal detector without any misadjustment can be easily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com