Wheel set press-fitting machine and wheel set press-fitting method

A press-fitting machine and press-fitting technology, which is applied in the field of rail transit equipment, can solve the problems of frame deformation, large error, non-parallel repeatability of oil cylinder piston and guide rod, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

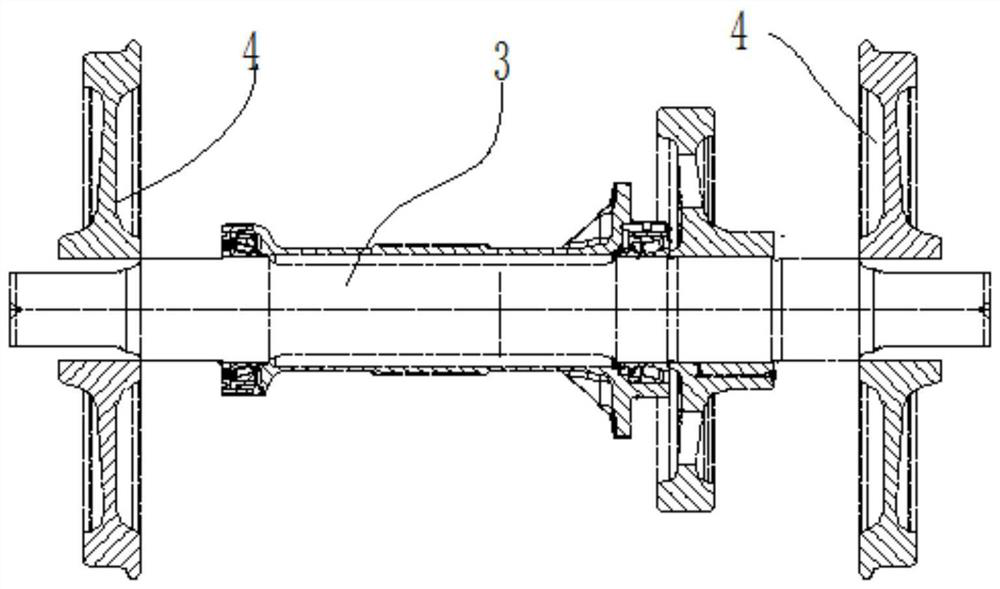

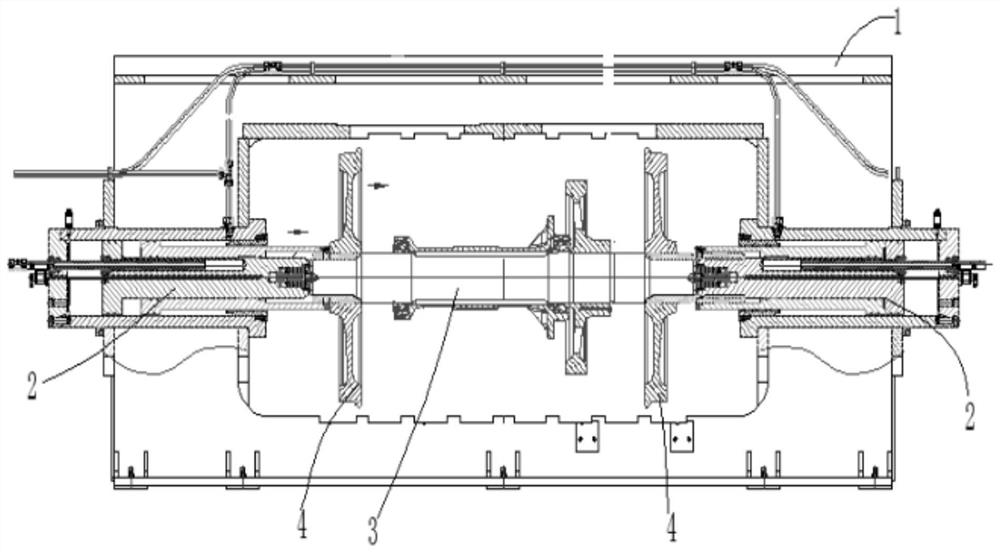

[0051] Such as figure 1 , 2 As shown, this embodiment provides a wheel pair press-fitting machine, which is used to press-fit the wheel 4 of the wheel set to be pressed into place on its axle 3, and the wheel set to be pressed includes the wheel axle 3 and the wheel set pre-installed on the wheel axle 3. The wheels 4 at the two ends of the wheel shaft 3, the wheel pair press-fitting machine includes a frame 1, two press-fitting mechanisms 2, and a controller, the press-fitting mechanisms 2 are electrically connected to the controller, and the two press-fitting mechanisms 2 are distributed at intervals along the left and right directions and fixed horizontally on the left and right ends of the frame 1 respectively. The press-fitting of the wheels 4 at both ends of the wheel shaft 3 is in place, and the press-fit mechanism 2 also includes a displacement sensor 26, and the displacement sensor 26 is used to detect the protruding length when the press-fit mechanism 2 clamps the wh...

Embodiment 2

[0057] Such as Figure 4 As shown, the same as embodiment 1, the difference is that the wheel set press machine provided in this embodiment also includes two displacement measurement mechanisms 5, the displacement measurement mechanisms 5 are electrically connected to the controller, and the two displacement measurement mechanisms 5 is installed on the frame 1, and the two displacement measuring mechanisms 5 are in one-to-one correspondence with the two wheels 4, and the displacement measuring mechanism 5 is used to measure the inner surface of the corresponding wheel 4 and the axle 3 The spacing between the middle positions corresponding to the length direction.

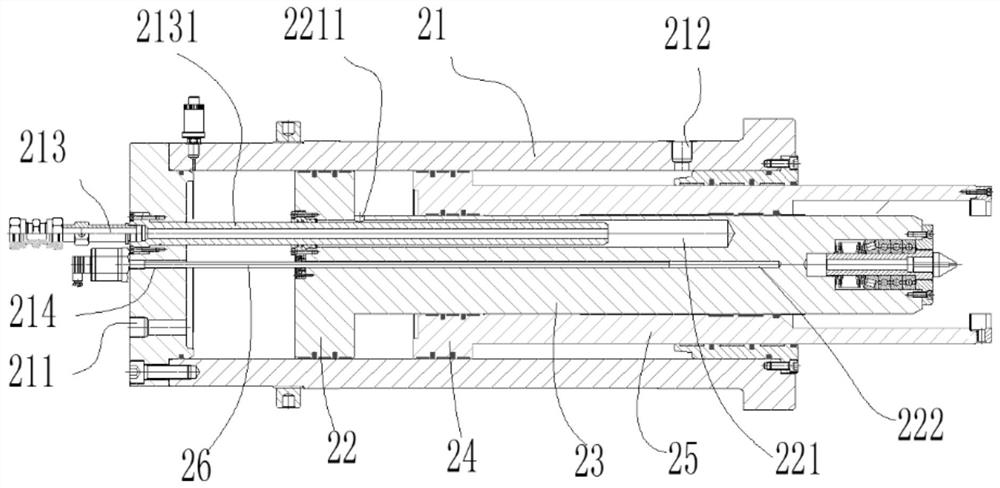

[0058] And the bottom of the piston cylinder 21 is provided with a mounting hole 214, the end of the first piston 22 away from the cylinder mouth of the piston cylinder 21 is recessed with a slotted hole 222 extending into the piston rod 23, and The installation hole 214 and the slot hole 222 are aligned with each ...

Embodiment 3

[0069] Such as Figure 6 As shown, with embodiment 2, the difference is that the displacement measuring mechanism 5 in this embodiment is an infrared range finder, which is suspended in the frame 1 by a bracket, and is located between the two wheels 4. The middle part, and its measuring part faces the wheel 4, so that the distance between the corresponding inner surface of the wheel and the centering surface can be measured by two infrared range finders.

[0070] The principle of this embodiment is to directly use the infrared rangefinder instead of the measuring ruler as the only measuring mechanism, which is convenient for measurement, does not need to be in contact with the wheel, and occupies a small space.

[0071] Wherein, in embodiment 2 and embodiment 3, the controller controls the expansion and contraction of the chuck and the push ring of the press-fitting mechanism by controlling the oil supply or oil return of the oil supply system of the press-fitting mechanism, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com