Active-passive joint-arm type measuring robot

A measurement robot, active and passive technology, applied in the field of robots, can solve the problems affecting the measurement accuracy, unable to obtain the position of the origin coordinate system, unable to meet the measurement accuracy requirements, etc., to achieve high measurement accuracy, easy handling, and avoid measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

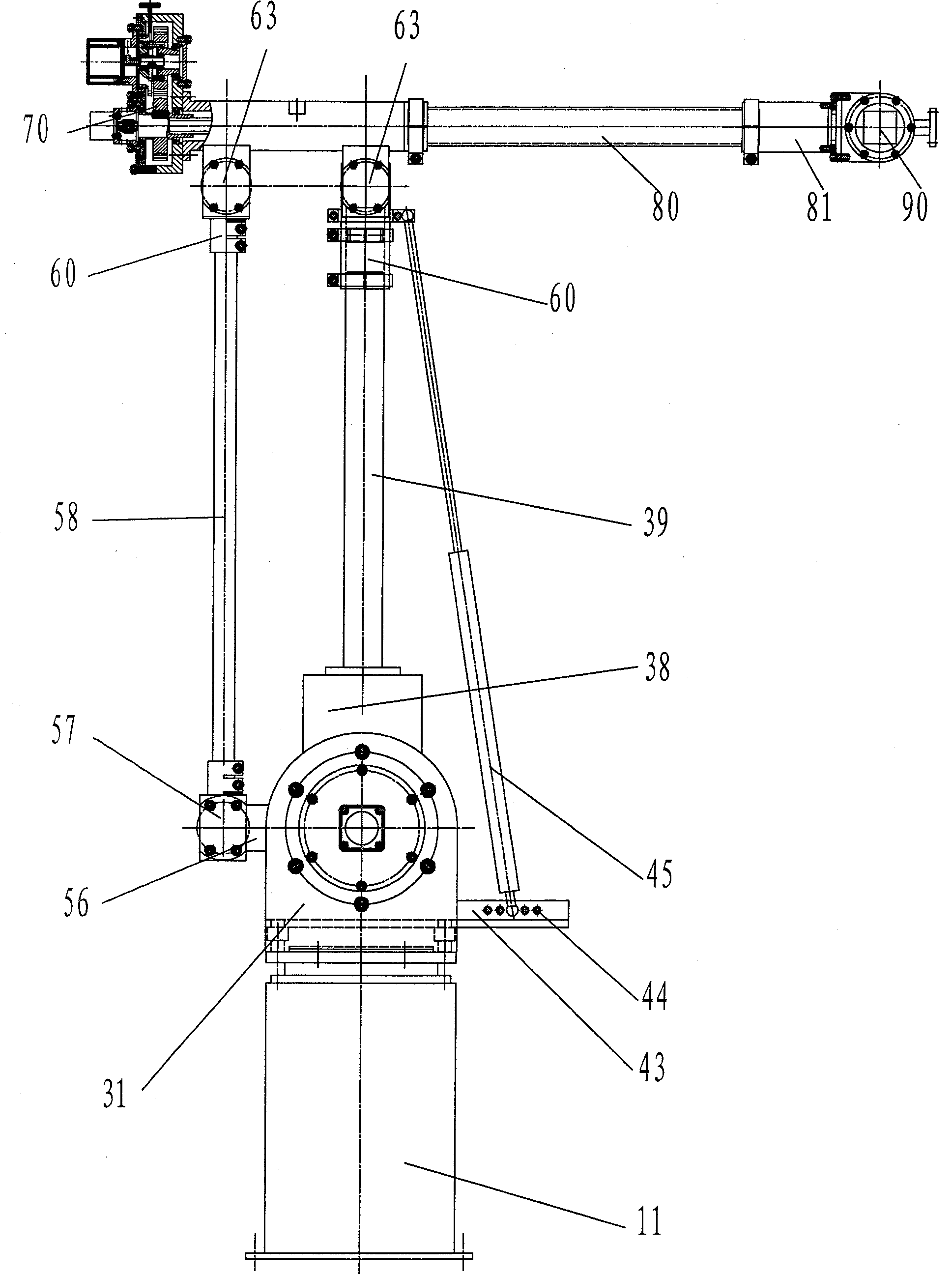

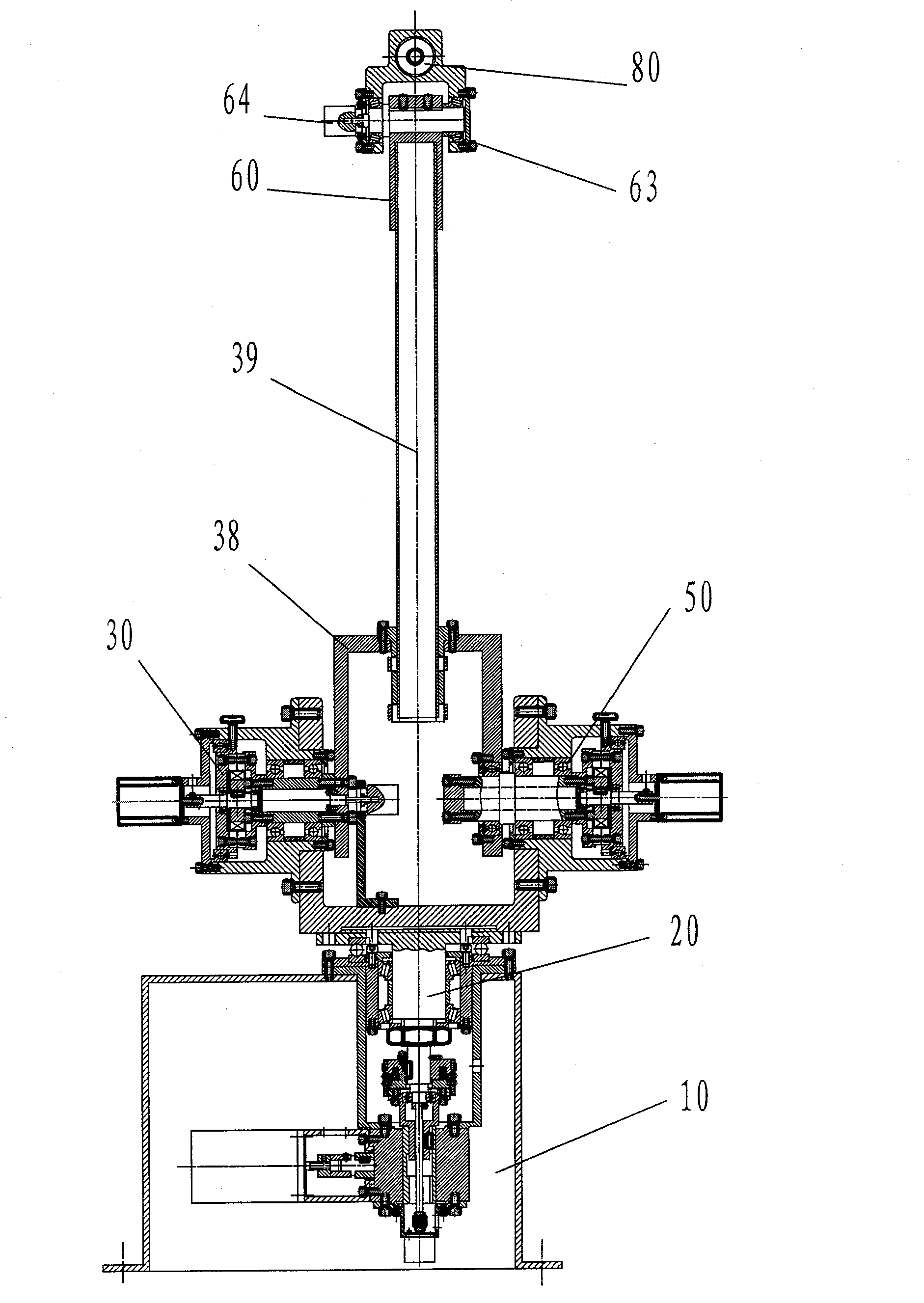

[0025] Such as figure 1 , figure 2 As shown, the present invention mainly includes I shaft assembly 10 , II shaft assembly 30 , III shaft assembly 50 , IV shaft assembly 70 and V shaft assembly 90 .

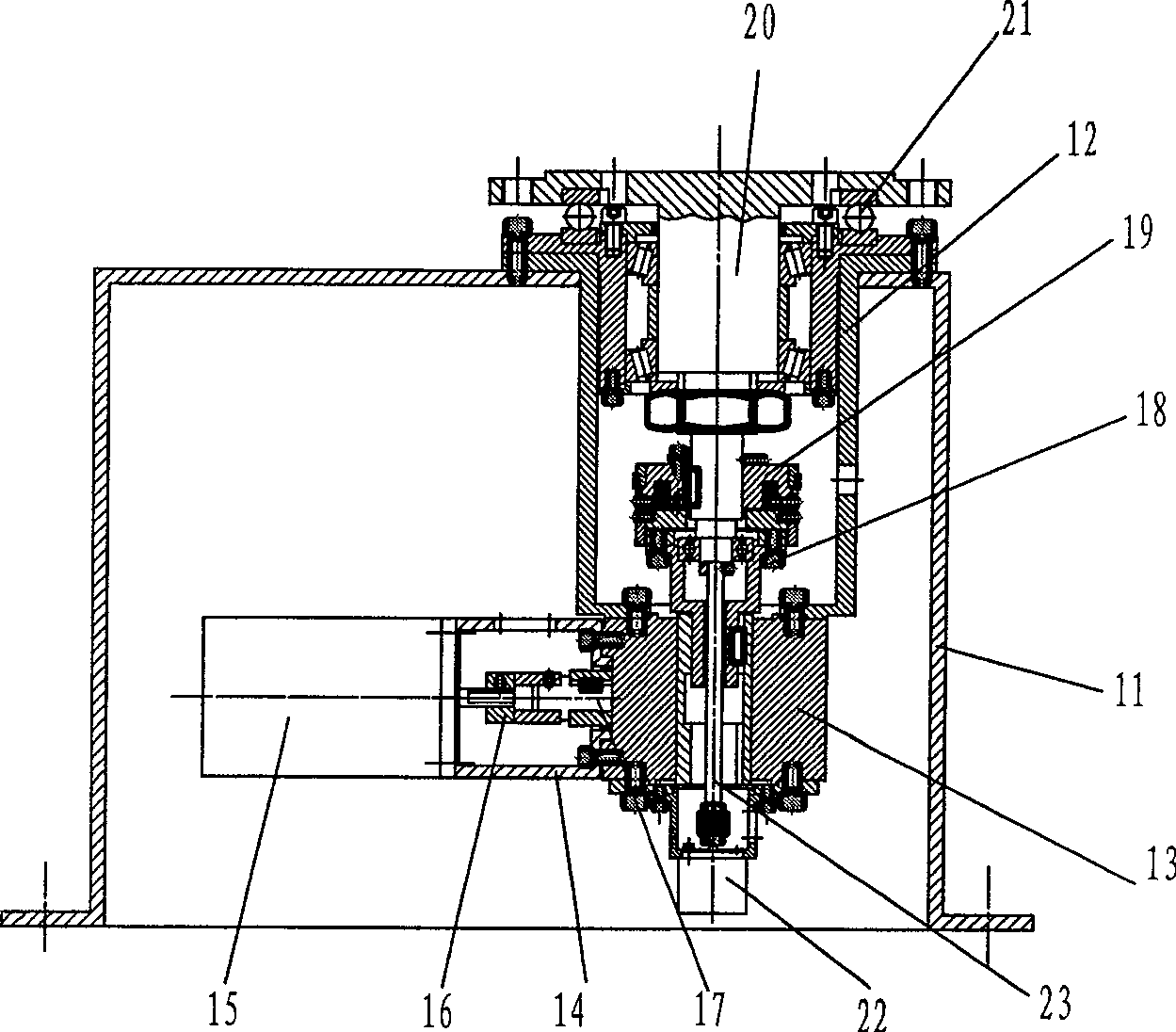

[0026] Such as figure 2 , image 3 As shown, the I-shaft assembly 1 of the present invention comprises a support 11, extends downwards at the top of the support 11 and fixes a shaft cylinder 12, and the bottom of the shaft cylinder 12 is provided with a worm gear reducer 13 of the prior art. One side of the casing of the device 13 is connected to an I-axis motor 15 through a flange 14, and the I-axis motor 15 is connected to the worm 17 of the speed reducer 13 through a coupling 16, and the worm gear output shaft 18 meshed with the worm 17 passes through an electromagnetic clutch 19 It is connected with an I-shaft (main output shaft) 20 coaxial wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com