Dynamic weighing correction method based on deep neural network in digital twin environment

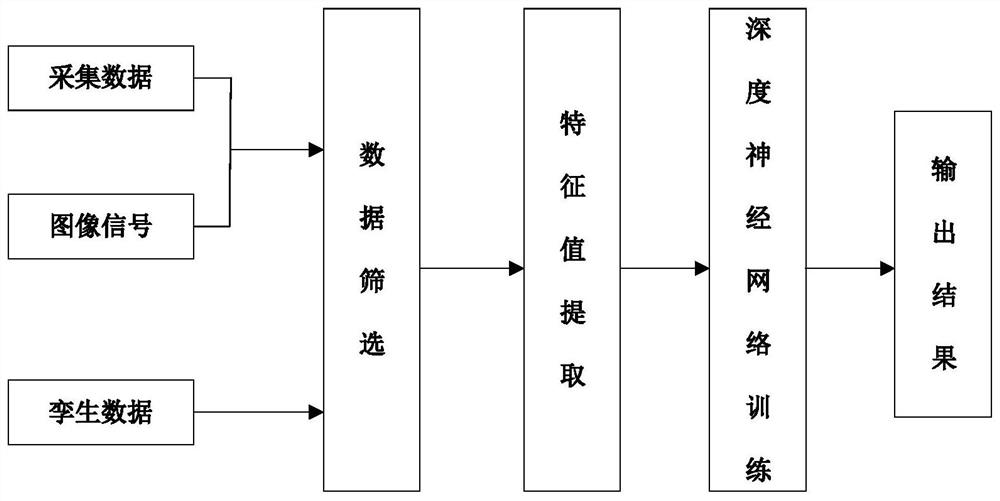

A deep neural network and dynamic weighing technology, which is applied in the identification scheme for drivers' weight loss and toll evasion, and in the field of dynamic weighing correction, can solve the problem of low measurement accuracy, achieve accurate simulation data, improve measurement accuracy, and enrich samples The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

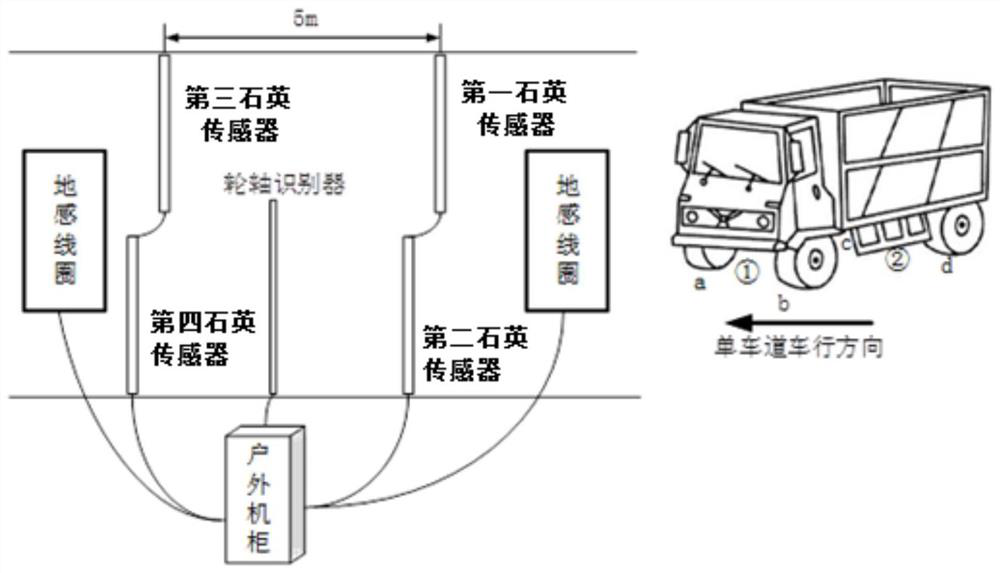

[0049] (1) Firstly, rationally arrange the quartz sensor and camera device, and build the detection device of the dynamic weighing correction system, so as to build a road-vehicle-scale digital twin system;

[0050] Due to the shortcomings of traditional quartz load cells such as uneven pressure sensitivity, sensitivity to environmental changes, rough processing, and low assembly accuracy, the high-speed dynamic weighing system optimizes the quartz sensor used. The installation position of the chip should be used to avoid uneven pressure sensitivity. Secondly, aluminum materials with low impact on environmental changes should be selected. Finally, the shortcomings of traditional quartz load cells should be improved by precision machining of pressure planes, quartz assembly planes and high-precision assembly. .

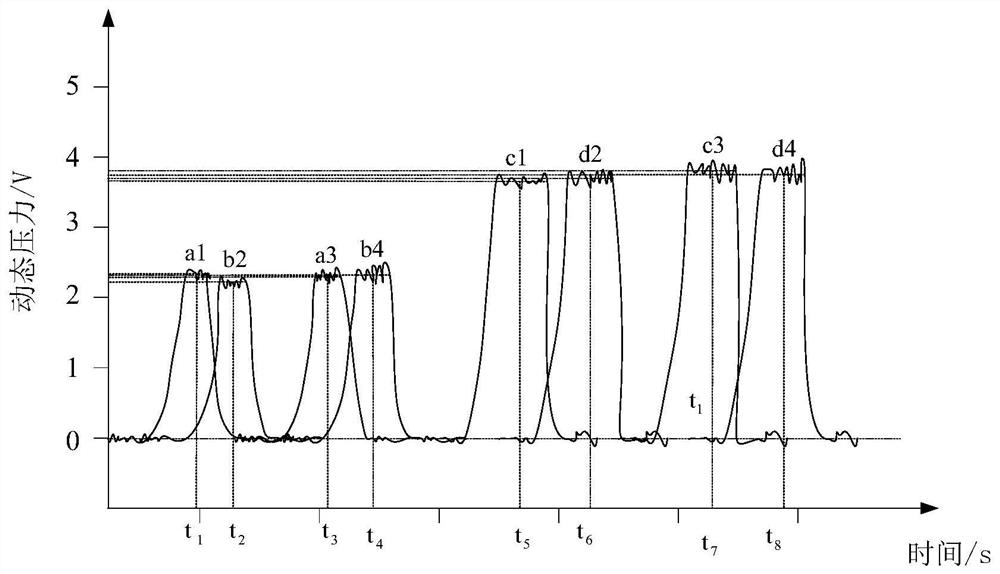

[0051] The sensor arrangement is as figure 1 As shown, it is assumed that the weighing area S is 5 meters, and the four quartz load cells used are dislocated in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com