Turntable error identification and compensation method for cylindrical coordinate measuring machine

A technology of cylindrical coordinates and compensation methods, applied in the field of precision measurement, can solve problems such as difficult compensation of geometric errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific drawings and embodiments.

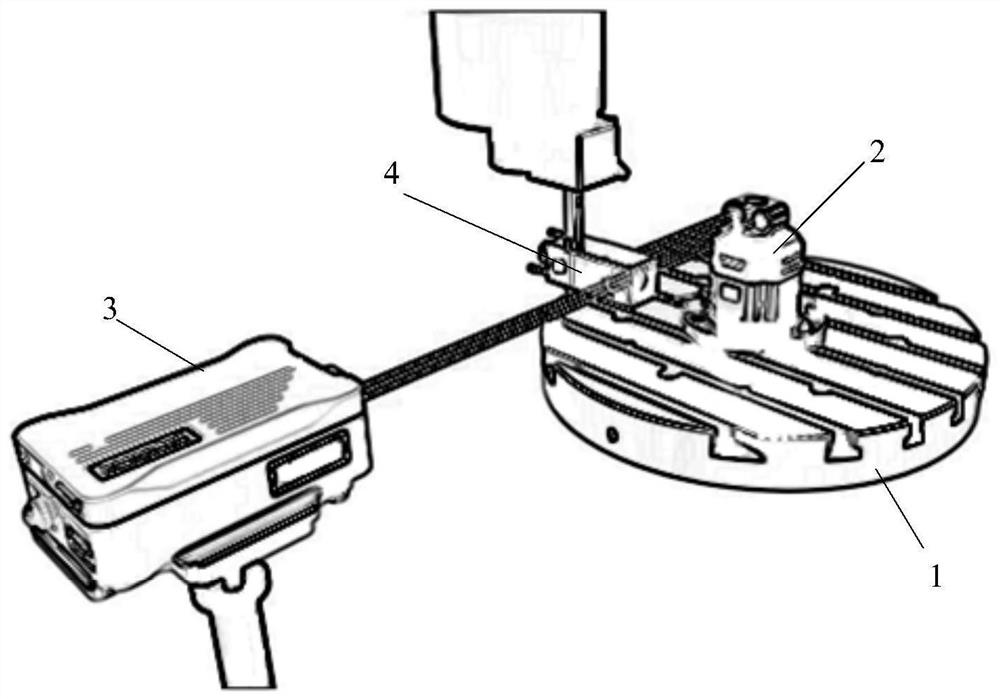

[0037] A method for identifying and compensating errors of a turntable of a cylindrical coordinate measuring machine proposed in an embodiment of the present invention includes:

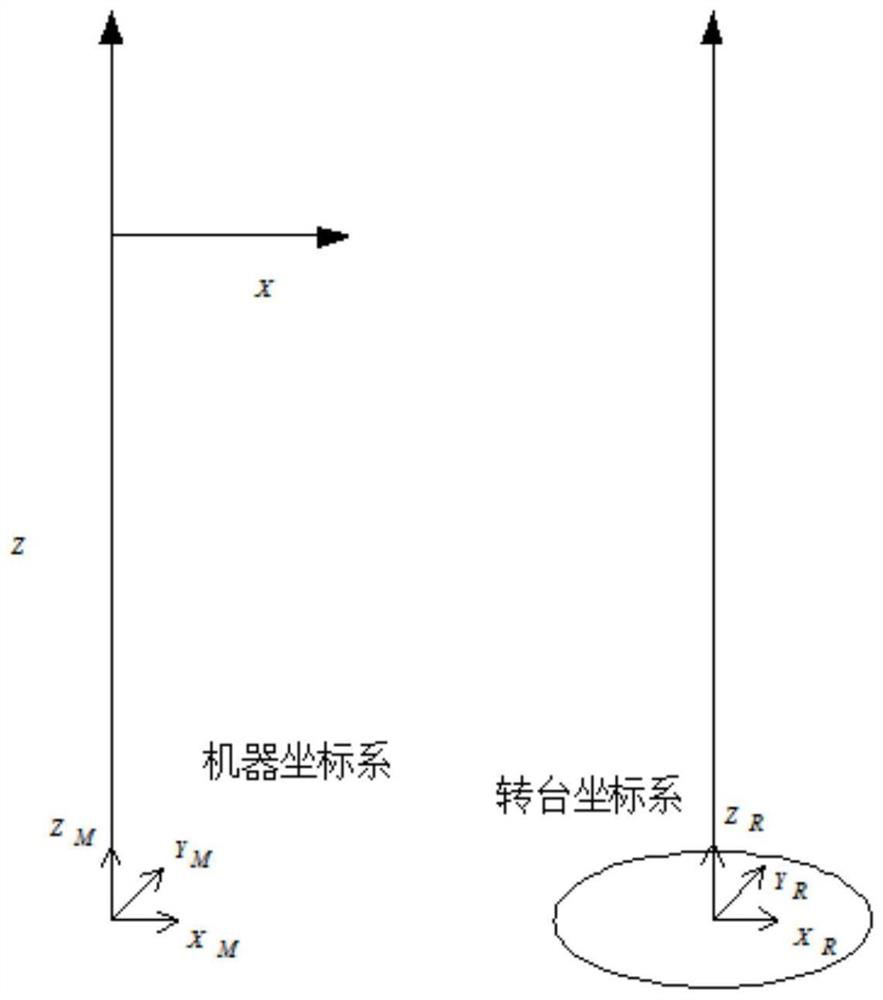

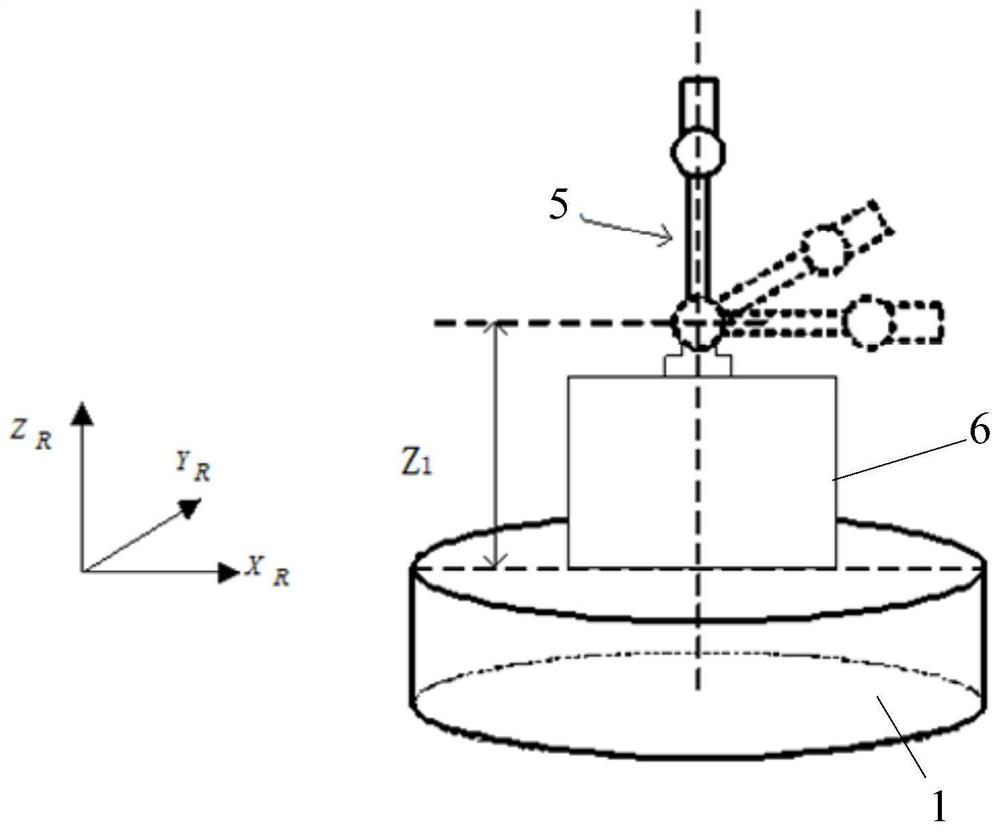

[0038] First establish the machine coordinate system O-X according to the cylindrical coordinate measuring machine M Y M Z M , define the two translational axes as X-axis and Z-axis respectively, and establish the turntable coordinate system O-X at the center of the turntable R Y R Z R , its structure is as attached figure 1 shown;

[0039] Based on the assumption of small error deformation and the principle of rigid body homogeneous coordinate transformation, the geometric error model of the turntable is established. When the rotation angle of the turntable is θ, the corresponding geometric error transformation matrix of the turntable is:

[0040]

[0041] where δ xc ,δ y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com