Single-point weight metering system, weighing device and weighing method

A weighing device and weighing technology, applied in measurement devices, weighing equipment using elastically deformable parts, weighing, etc., can solve the problems affecting the accuracy and stability of the measurement results of electronic weighing instruments and measurement stability, the limitation of the application range of load cells, etc., to avoid thermal stability problems, avoid mechanical errors and temperature effects, and achieve the effect of novel principles and technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] In this embodiment, the elastic body 3 is made of carbon fiber composite material.

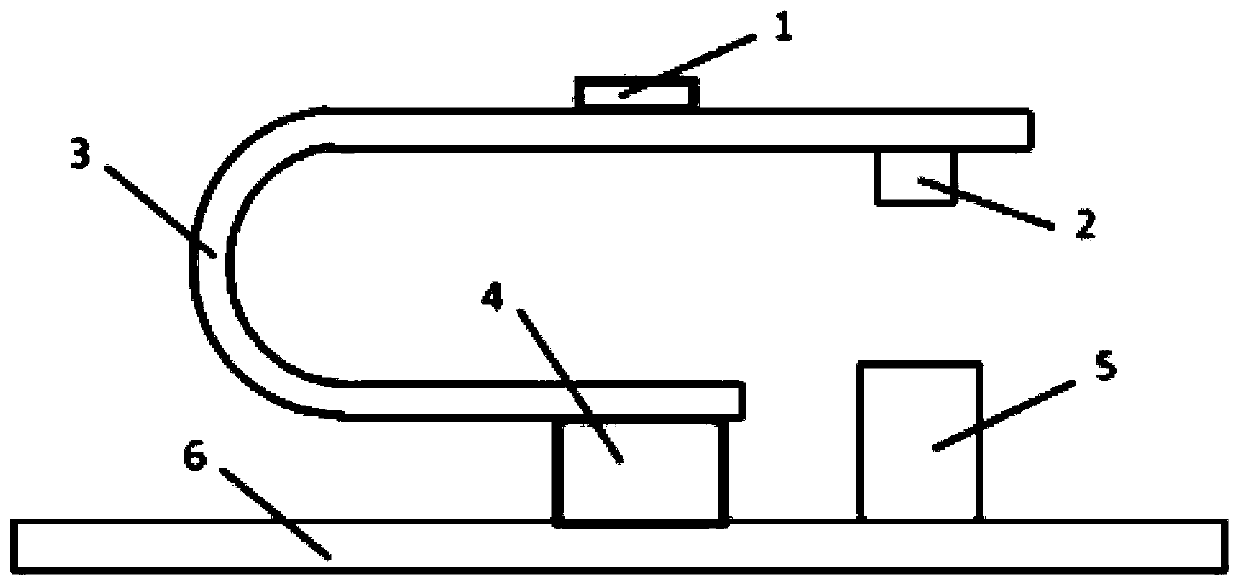

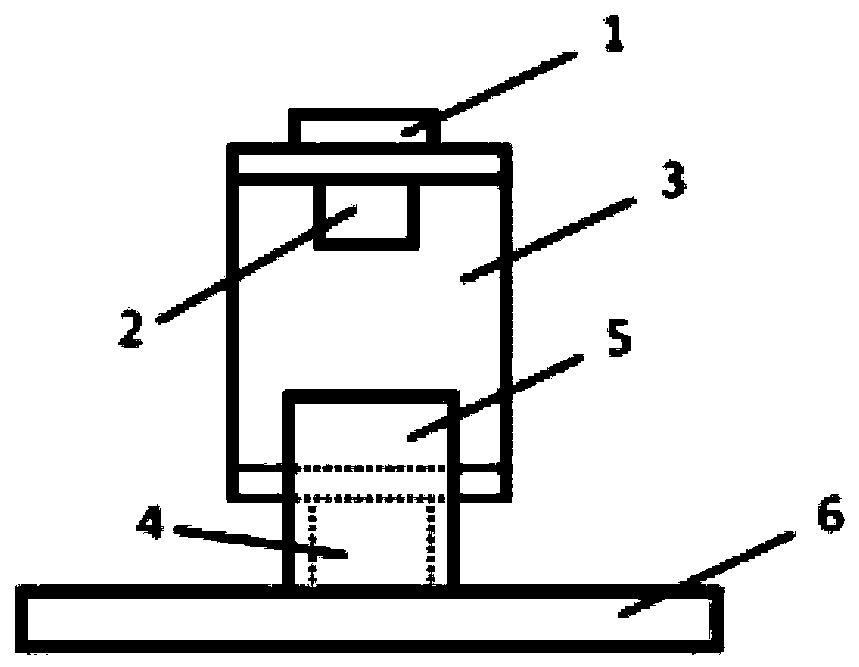

[0076] The single-point weighing system includes a sub-bearing body 1 and a supporting seat 5. The elastic body 3 is a horizontal "U"-shaped structure. The supporting seat 5 is installed on the bottom surface of the lower extension of the elastic body 3. The sub-bearing body 1 is installed On the top surface of the upper extension part of the elastic body 3 , the monitored device is installed on the bottom surface of the upper extension part of the elastic body 3 .

[0077] Specifically, such as Figure 1-Figure 4 As shown, this implementation example proposes a weighing device with no angle difference and good thermal stability designed and implemented by applying the technical solution of the present invention.

[0078] The weighing device with no angle difference and good thermal stability is composed of 4 sets of independent single-point weighing systems, a load-bearing rigid body ...

Embodiment 2

[0106] In this embodiment, the elastic body 3 is made of carbon fiber composite material.

[0107] The single-point weighing system includes a sub-bearing body 1, and the elastic body 3 includes an "L"-shaped structure composed of a vertical extension body and a horizontal extension body. The lower end of the vertical extension body is fixed, and the first end of the horizontal extension body is connected to the vertical On the upper end of the straight extension body, the monitored device is arranged in the middle of the bottom surface of the horizontal extension body, and the sub-bearing body 1 is arranged at the bottom of the second end of the horizontal extension body.

[0108] Specifically, such as Figure 5-Figure 9 As shown, this implementation example proposes a weighing device with no angular difference and good thermal stability designed and implemented by applying the technical solution of the present invention.

[0109] A weighing device with no angle difference a...

Embodiment 3

[0116] In this embodiment, the elastic body 3 is made of carbon fiber composite material.

[0117] The single-point weighing system also includes a sub-bearing body 1 and a support seat 5, the elastic body 3 is in the shape of a strip, and the support seat 5 is arranged on the first end of the bottom surface of the elastic body 3, and the sub-force-bearing body 1 is arranged on the top surface of the second end, and the monitored device is arranged on the bottom surface of the second end.

[0118] Such as Figure 10 , Figure 11 as shown,

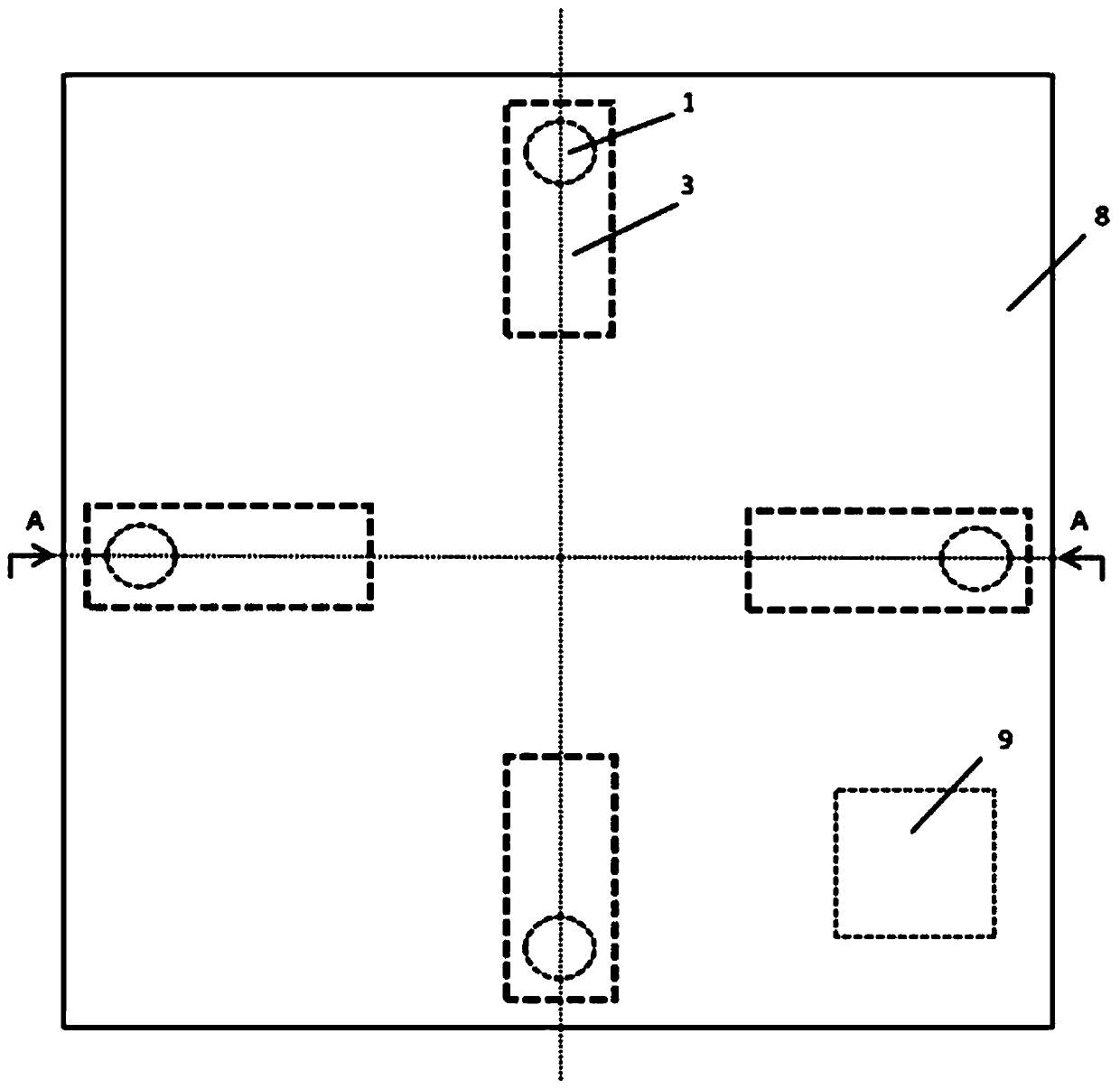

[0119] A single-point weighing system with no angle difference and good thermal stability is composed of 4 sets of independent single-point weighing systems, a force-bearing rigid body 8, a data processing circuit 9, and a force-transmitting cone 7.

[0120] A weighing device with no angular difference and good thermal stability constitutes a complete 4-point weighing system.

[0121] 4 sets of independent single-point weighing systems,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com