Storage forklift acceleration device

A technology for acceleration devices and forklifts, applied in the layout of power plant control mechanisms, electric vehicles, vehicle components, etc., can solve the problems of mechanical errors of the transmission mechanism, decreased precision, and vehicle out-of-control, to avoid mechanical errors, stable operation, and effective reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

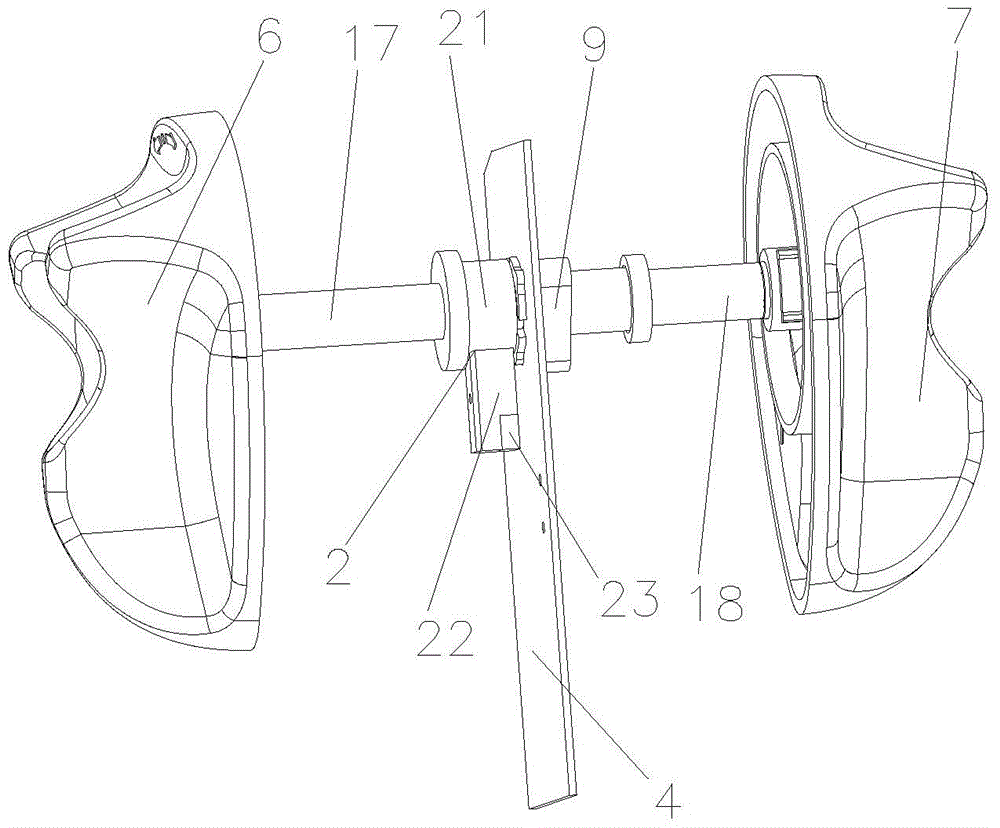

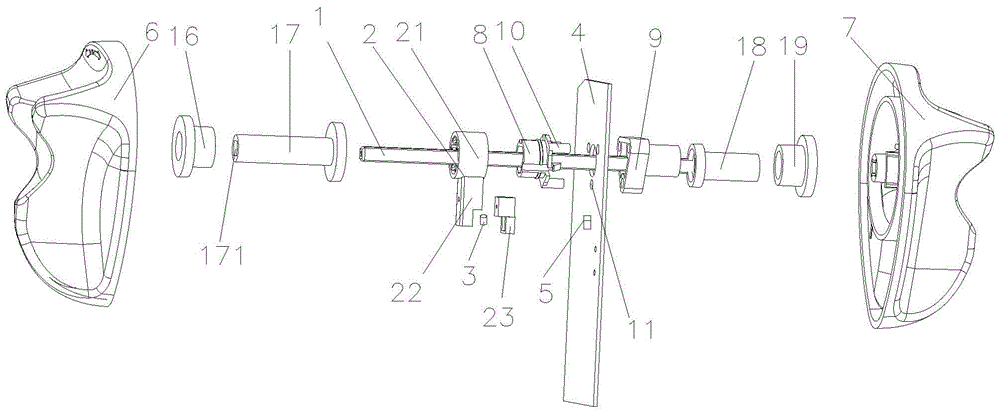

Image

Examples

Embodiment 1

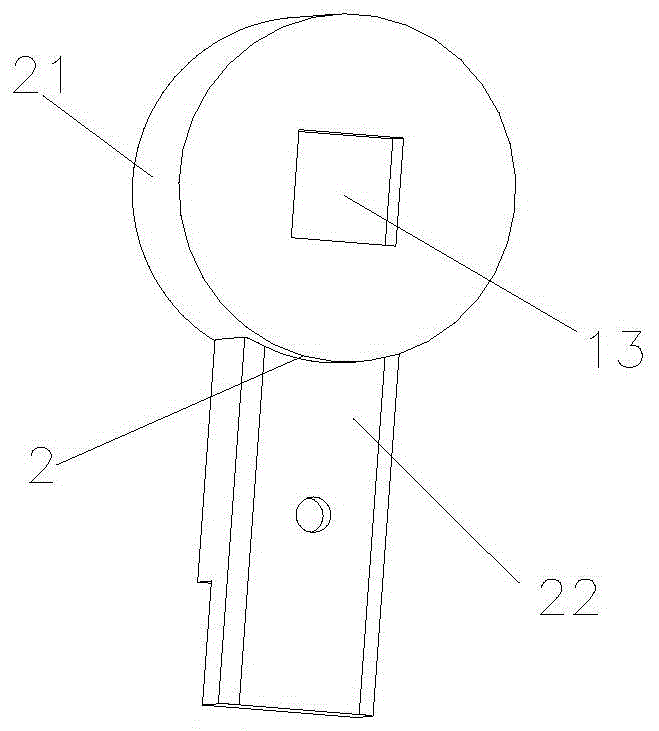

[0038] Embodiment 1: as image 3 , the section of the knob shaft 1 is rectangular, and the side of the connecting portion 21 away from the fixed block one 8 is provided with a first rectangular through hole 13 matching the outer surface of the knob shaft 1 .

Embodiment 2

[0039] Embodiment 2: as Figure 4 The side of the connection part 21 far away from the fixed block 8 is a hollow semi-closed structure, and the center of the side of the connection part 21 away from the fixed block 8 is provided with a second rectangular through hole 14 matching the outer surface of the knob shaft 1. Between the four vertices of the two rectangular through holes 14 and the inner wall of the connecting part 21, there is an S-shaped connecting bracket 15 lying along one direction. The bracket helps to offset part of the tension generated by the rotation, effectively preventing the junction of the connecting bracket and the connecting part, the junction of the connecting bracket and the outer frame of the second rectangular through hole, and the possibility of fracture and damage of the connecting bracket, which greatly improves stable effect, at the same time, the protection scope of the present invention is not limited to the two cases of embodiment 1 and embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com