Water-oil isolation type soaking three-axis testing tank and testing method

A triaxial test, isolation technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of experimental result errors, long-term water immersion and confining pressure changes, etc. , to achieve the effect of simple and easy methods and steps, convenient collection of experimental data, and avoidance of mechanical errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

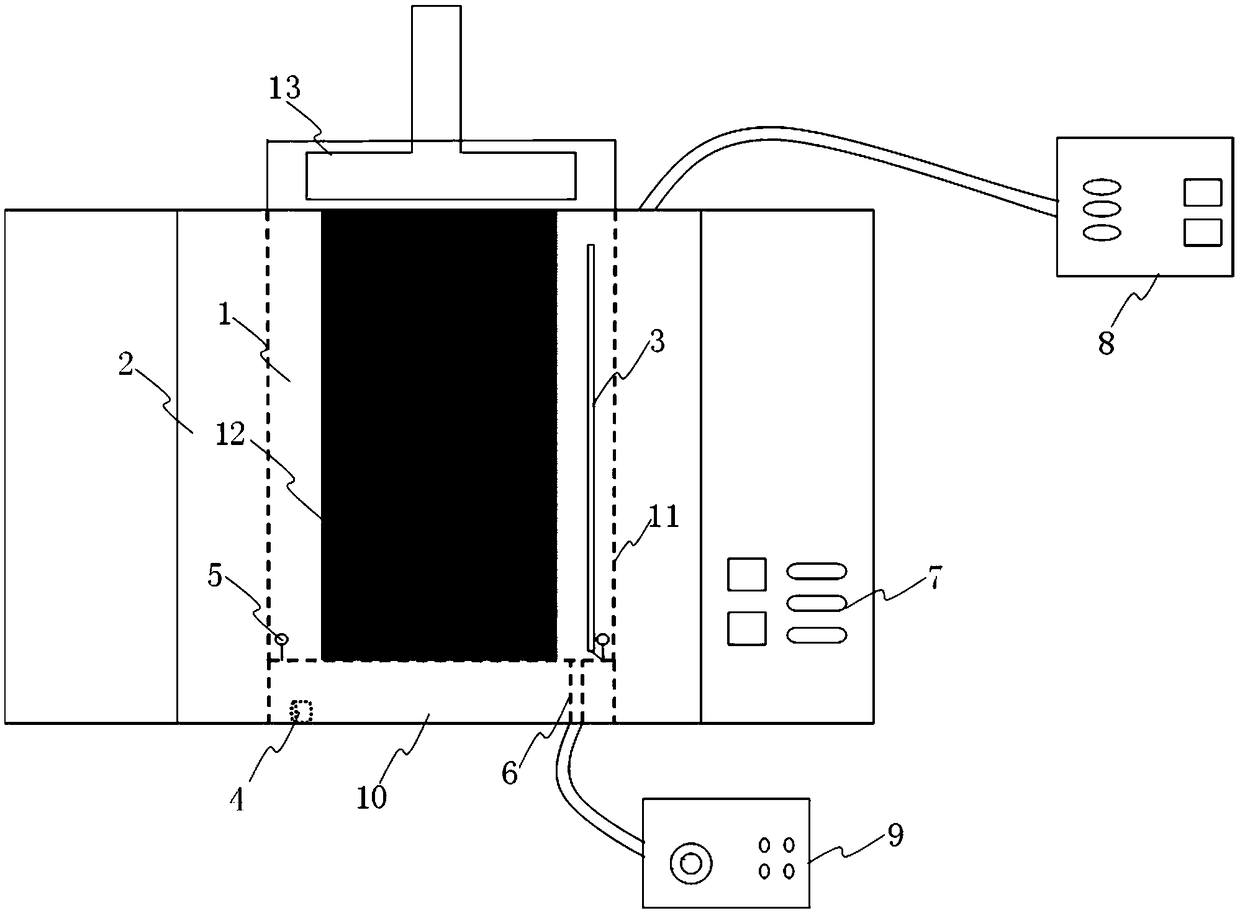

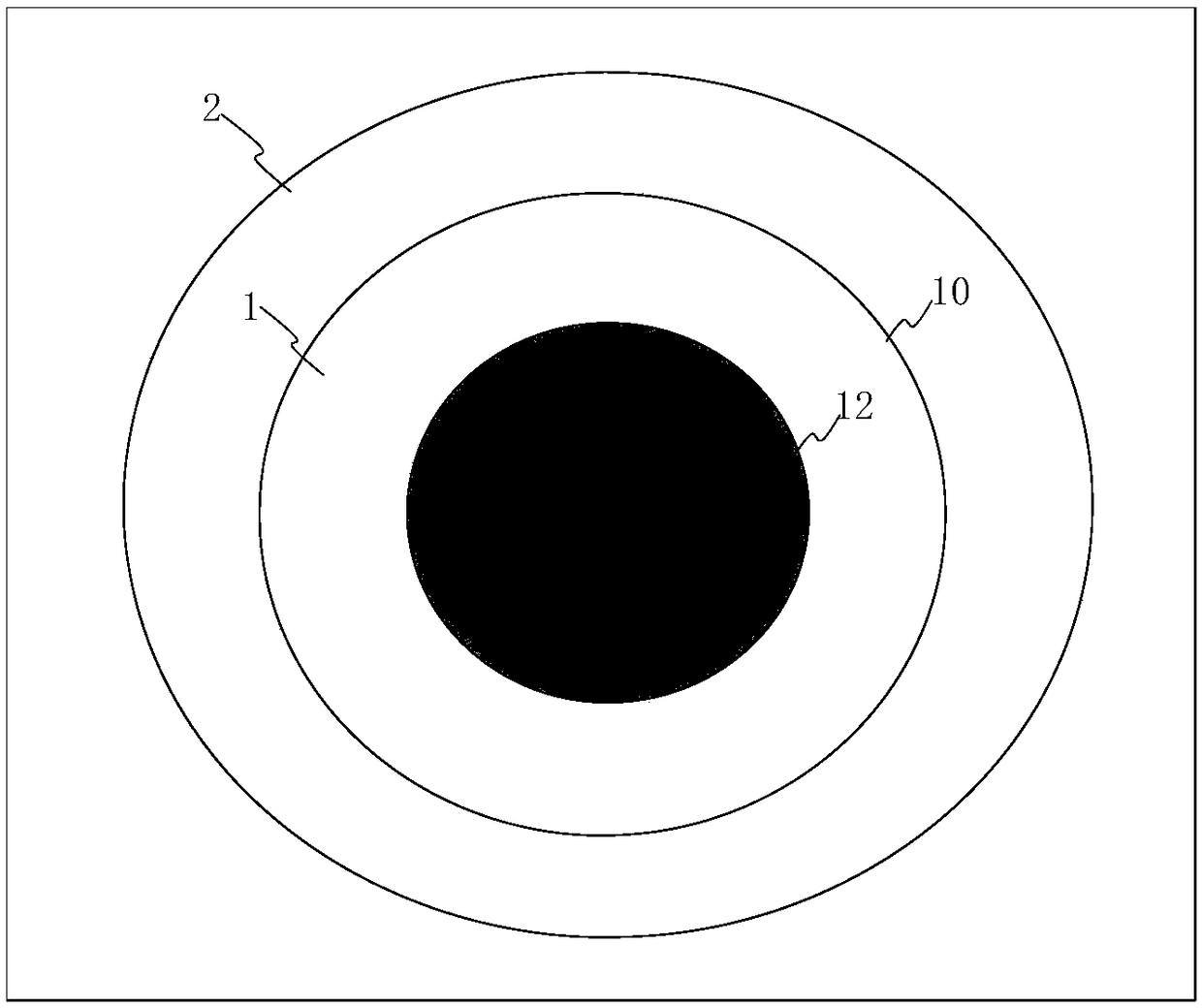

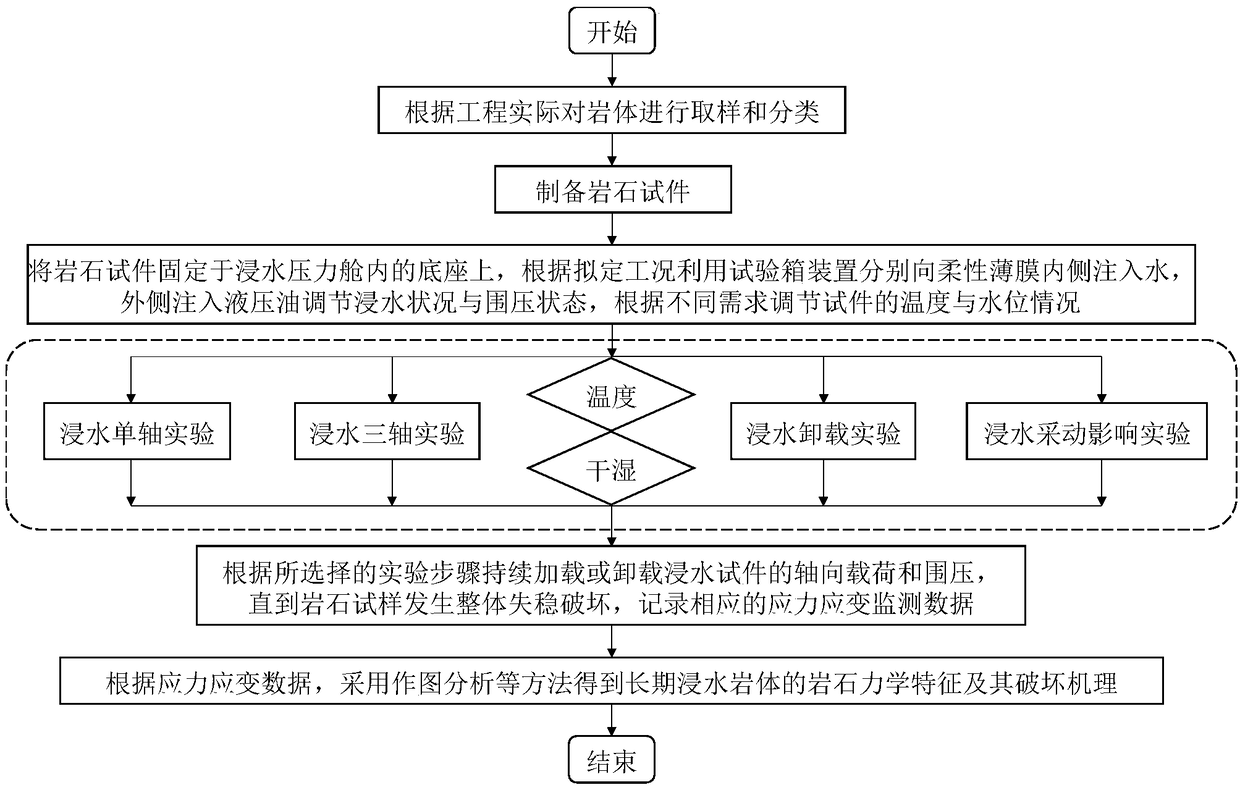

[0037] combine Figure 1 to Figure 3As shown, the specific implementation of a water-oil isolation type submerged triaxial test chamber and test method provided by the present invention is as follows.

[0038] A water-oil isolation type submerged triaxial test chamber specifically includes a water-immersion pressure chamber 1, a hydraulic oil chamber 2, a heater 3, a pressure sensor 4, a temperature sensor 5, a seepage channel 6, a refrigeration device 7, an oil pressure control device 8 and a seepage The adjustment device 9 and each part of the test box can be disassembled freely, which is convenient for disassembly and assembly, and each part of the device also has the advantages of flexible cleaning and replacement. The heater 3 is set in the water immersion pressure chamber 1, and the refrigeration device 7 is set outside the hydraulic oil tank 2, so as to realize the heating and cooling of the test piece, and simulate the influence of freezing and thawing on the test piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com