Cable provided with heat shield with heat dissipation holes and wear-resisting layers

A technology of heat shield and wear-resistant layer, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as hidden safety hazards, heat accumulation, cable bending, etc., and achieve the effect of avoiding impact and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

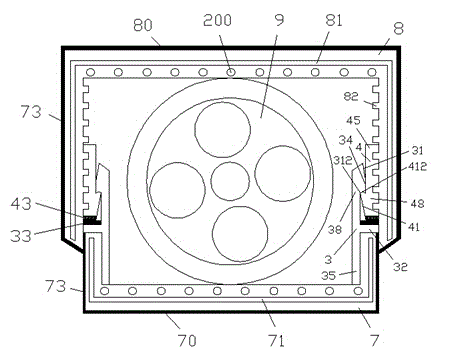

[0009] Combine below Figure 1-2 The present invention will be described in detail.

[0010] According to an embodiment, a cable with a heat shield with heat exhaust holes and a wear-resistant layer includes a cylindrical cable body 9 placed inside the heat shield and an upper heat shield 8 and a lower insulation The heat shield of the heat shield 7, the cover walls of the upper heat shield 8 and the lower heat shield 7 all include respective bottom walls 80, 70 and side walls positioned at both sides of the bottom walls 80, 70. walls, the bottom walls 80, 70 are in contact with the two diametrically opposite domes of the cable body 9 respectively, and cooling fluid passages 81 extending along the housing walls are respectively provided in the housing walls , 71, the bottom walls 80, 70 are provided with heat exhaust holes 200 parallel to the cooling fluid passages 81, 71, and the heat exhaust holes 200 are provided with twenty one or more than twenty one, In the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com