A Direct Pulling Residual Current Action Tripping Mechanism

A technology of residual current and tripping mechanism, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of troublesome assembly, complex structure of tripping mechanism, high manufacturing cost, etc., and achieve convenient assembly, simple structure and reliable tripping performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

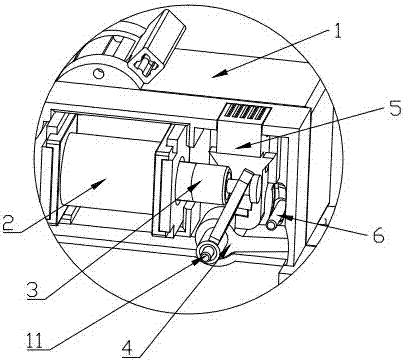

[0024] As shown in the figure, a direct pull type residual current action tripping mechanism includes a coil assembly 2, a moving iron core 3, a pull rod 4 and a reset button 5 arranged in the base 1 of the circuit breaker;

[0025] The coil assembly 2 is fixedly installed in the base 1;

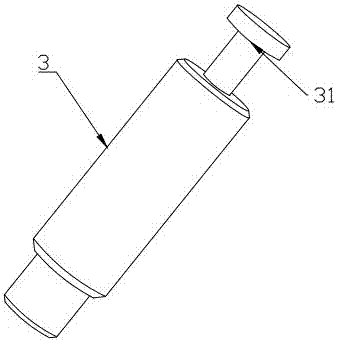

[0026] One end of the moving iron core 3 is slidably arranged in the center of the coil assembly 2, and the other end protrudes, and a "T"-shaped round platform 31 is provided;

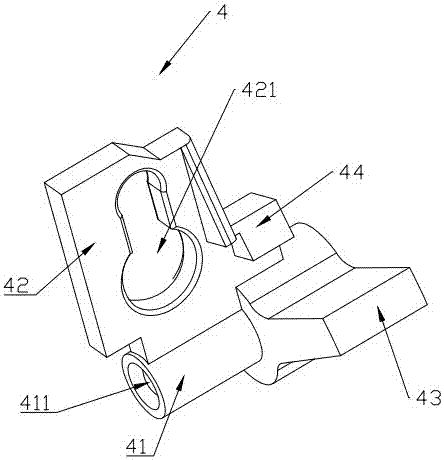

[0027] The pull rod 4 includes a hinge part 41, a first action arm 42, a second action arm 43, and a lock 44. The hinge part 41 is hinged to the base, and the surface of the first action arm 42 is provided with a gourd-shaped card slot. 421, cooperate with the round table 31 in linkage, and the second action arm 43 cooperates with the operating mechanism 6 of the circuit breaker;

[0028] The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com