Annular PN junction

A PN junction and ring-shaped technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of small tolerance of constant current value and low withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

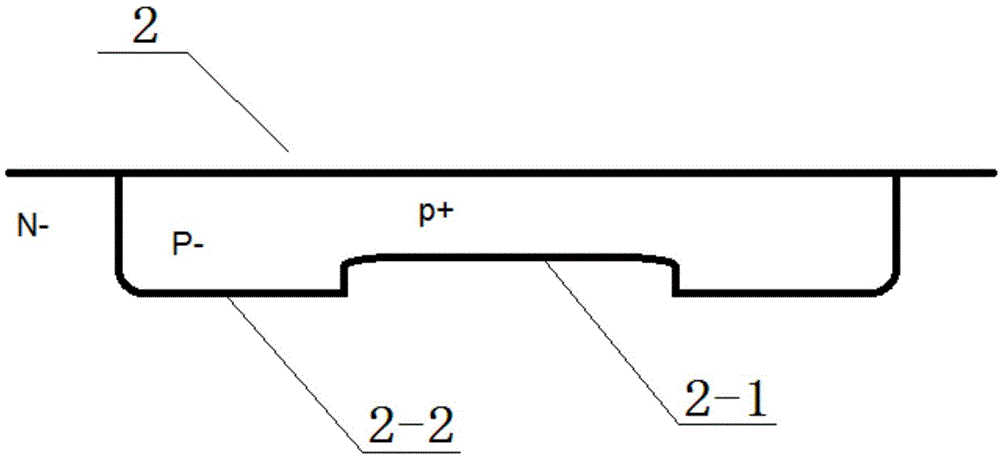

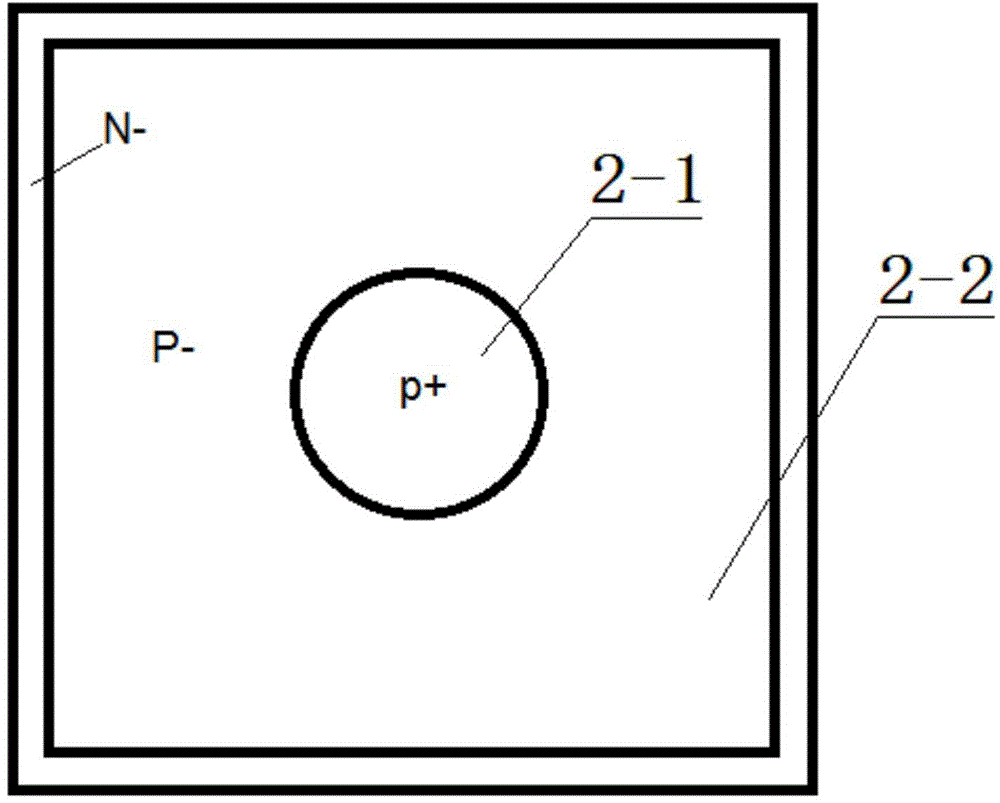

[0019] Embodiment 1, combining Figure 1-Figure 2 , a ring-shaped PN junction structure, the ring-shaped PN junction adopts a stepped PN junction 2, and a circular stepped surface depression 2-1 is constructed at the center of the PN junction surface, forming a stepped structure with the periphery 2-2.

Embodiment 2

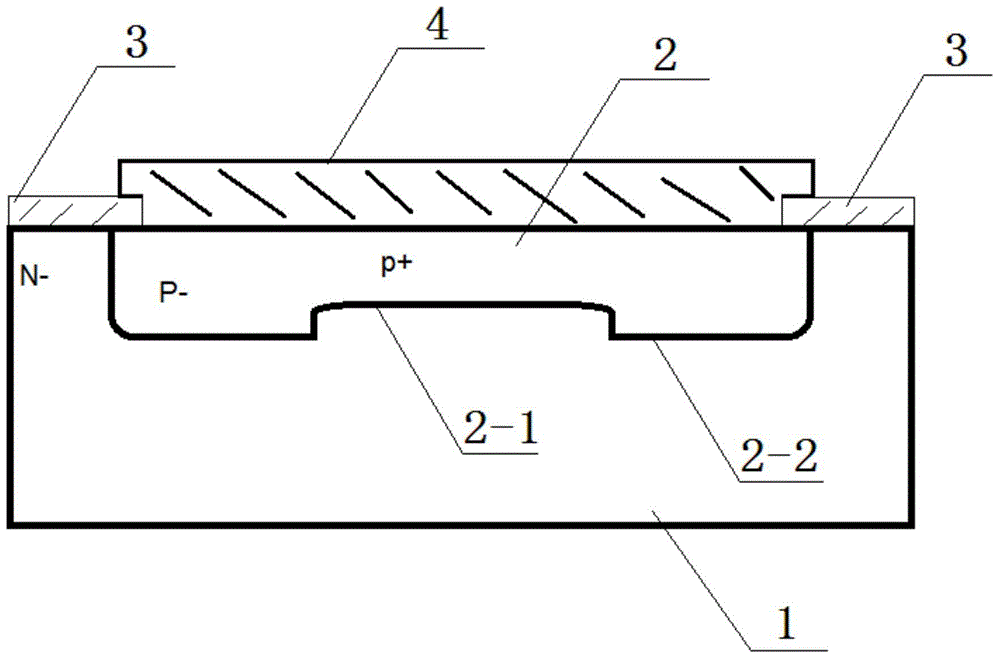

[0020] Example 2, combined with image 3 , a ring-shaped PN junction structure as described in Embodiment 1, which includes the step PN junction 2 described in Embodiment 1, the step PN junction 2 is embedded on the upper surface of the substrate 1, and the bottom of the step PN junction 2 is connected to the The upper surface of the substrate 1 is in the same plane; an oxide layer 3 is grown on the edge of the upper surface of the substrate 1, and the oxide layer 3 covers the stepped PN junction 2; an aluminum layer 4 is arranged above the bottom of the stepped PN junction 2, so Aluminum layer 4 and cover the edge of oxide layer 3 .

Embodiment 3

[0021] Embodiment 3, a ring-shaped PN junction structure as described in Embodiment 2, the substrate 1 is an N-type substrate with a thickness of 200 μm and a resistivity of 50; the thickness of the oxide layer 3 is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com