DC motor control method and device thereof

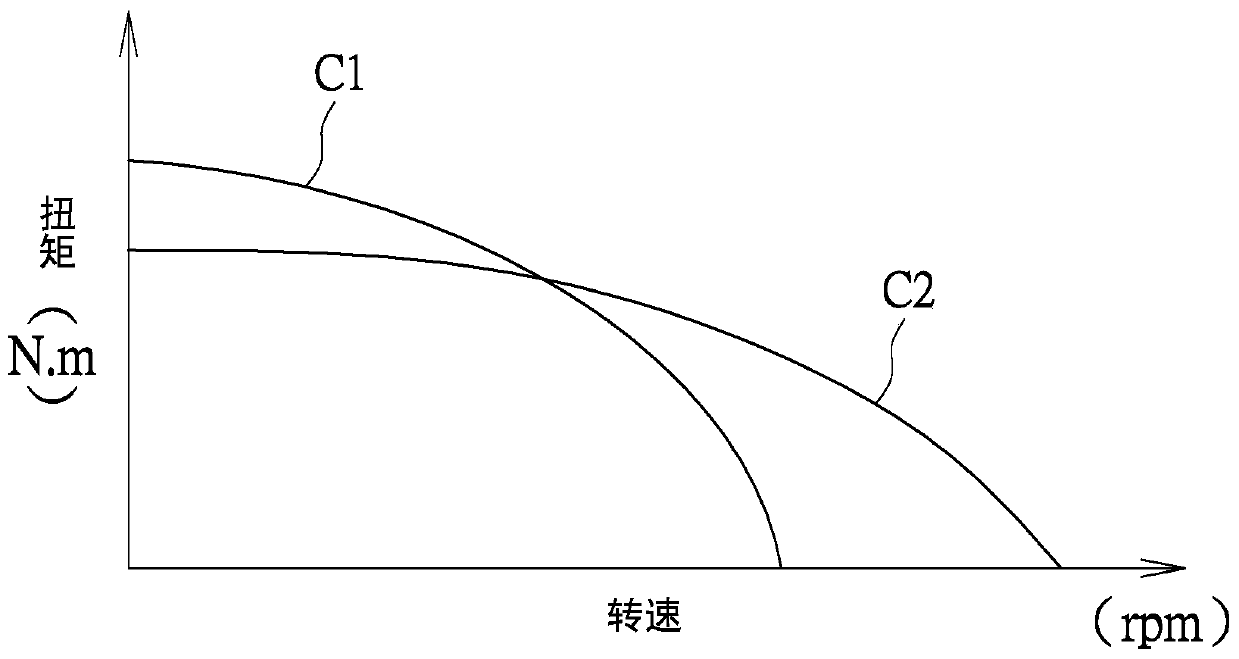

A DC motor and control device technology, applied in the field of motors, can solve problems such as insufficient torque of DC motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] [Example of DC motor control method]

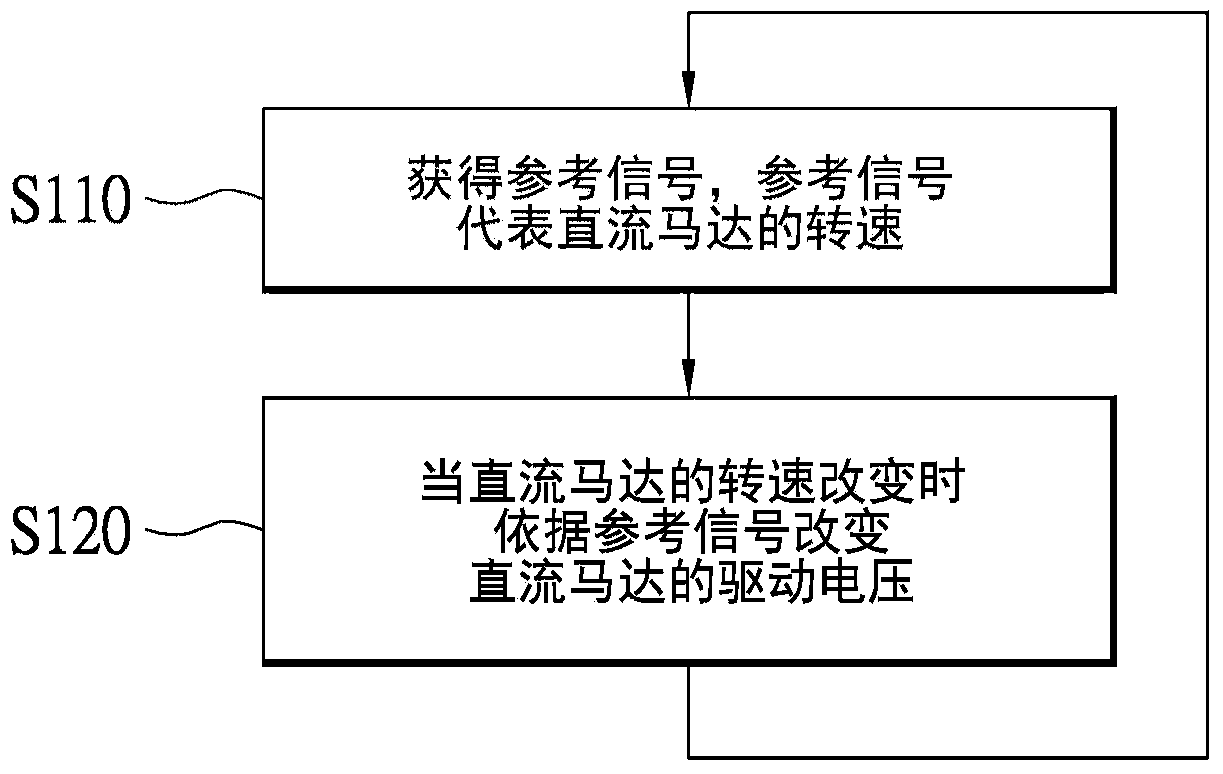

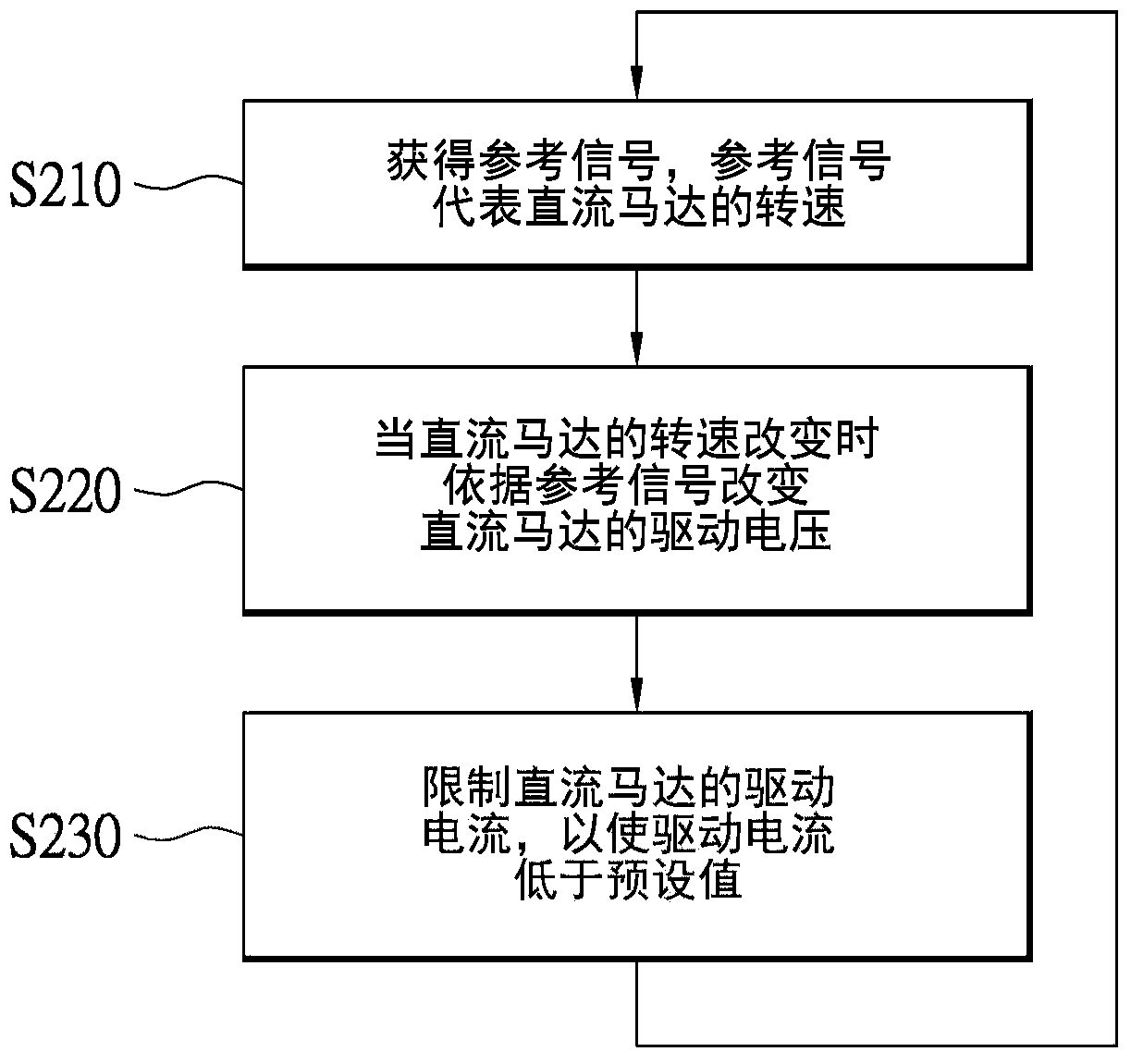

[0040] Please refer to Figure 2A , Figure 2A It is a flow chart of the DC motor control method provided by the embodiment of the present invention. The aforementioned DC motor may be, for example, a DC brushed motor, a DC brushless motor or a stepping motor. The DC motor can be applied to, for example, a drive motor of a printer, an electric fan for heat dissipation, a motor of a hard disk of a computer, etc., but the present invention is not limited thereto. The DC motor control method of this embodiment is used to control the DC motor, and the method includes the following steps.

[0041] In step S110, a reference signal is obtained, and the reference signal represents the rotational speed of the DC motor. Step S110 may be realized by using a rotational speed sensing unit to sense the rotational speed of the DC motor, for example, by sensing the magnetic pole position of the rotor of the DC motor to obtain the rotational sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com