Camera module

A camera module and lens technology, applied to cameras, camera bodies, TVs, etc., can solve problems such as low yield, easy deformation, and difficult operations, and achieve the effects of simple process, elimination of interference, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

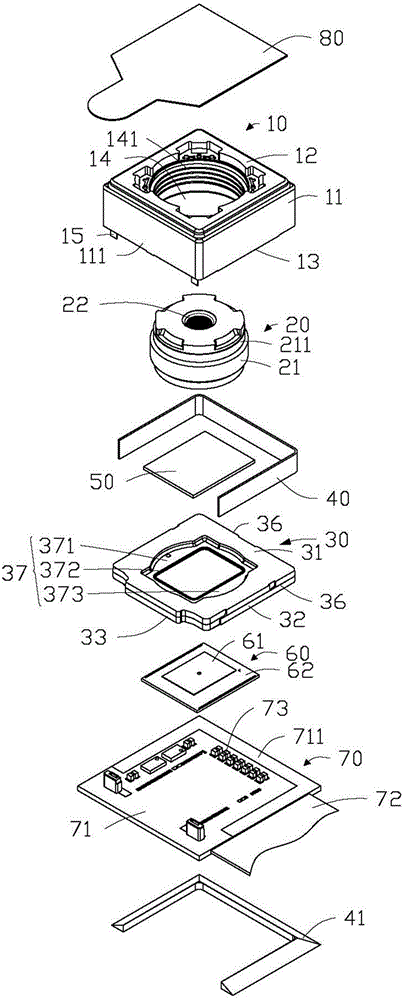

[0018] The structure of a camera module provided by the present invention will be further described below with reference to the drawings and embodiments.

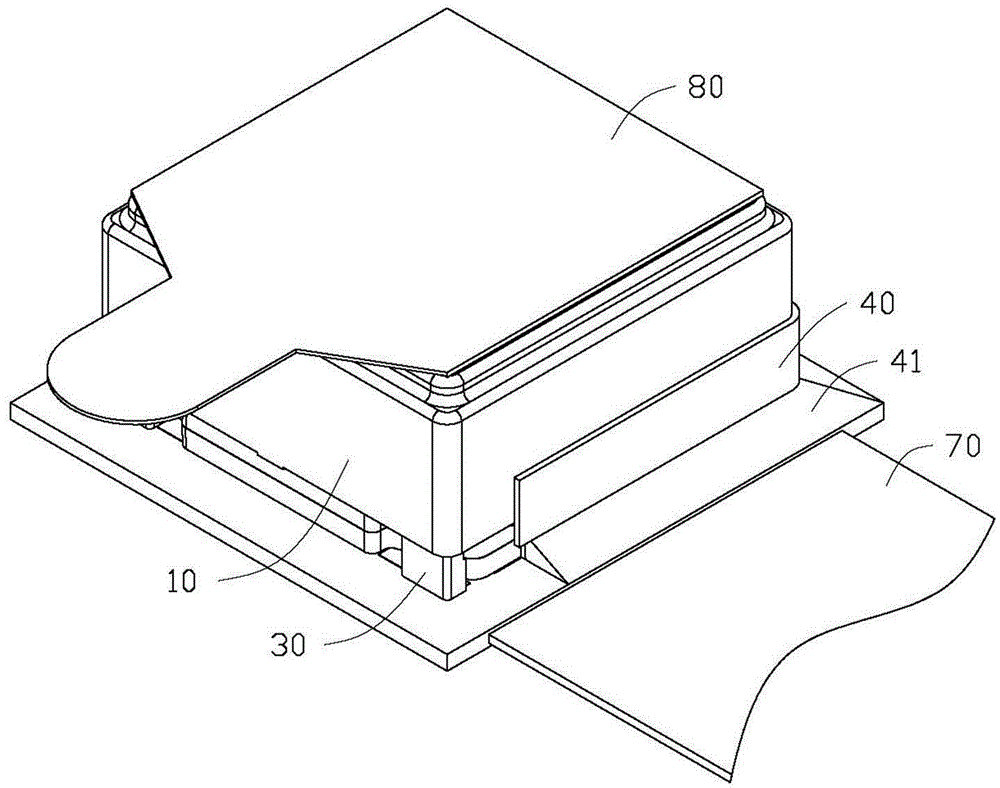

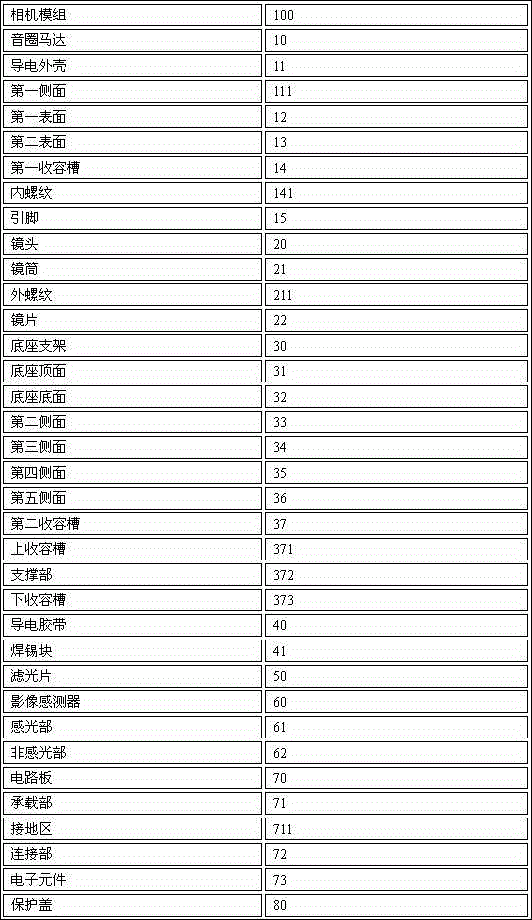

[0019] see Figure 1 to Figure 2 , a camera module 100 comprising a voice coil motor 10, a lens 20, a base bracket 30, a conductive tape 40, a filter 50, an image sensor 60, a circuit board 70 and a protective cover 80 .

[0020] The voice coil motor 10 is generally in the shape of a cuboid, and includes a conductive shell 11 , a first surface 12 and a second surface 13 opposite to the first surface.

[0021] The conductive shell 11 includes a first side 111 perpendicular to the first surface 12 and the second surface 13 . The conductive shell 11 can be made of magnetic shielding materials such as nickel-iron alloy, conductive plastic, surface conductive material, and conductive glass.

[0022] A middle portion of the first surface 12 defines a first receiving groove 14 for receiving the lens 20 . The first receiving gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com