Methods of processing waste activated sludge

A technology for activating sludge and waste, applied in chemical instruments and methods, protein components of waste, sludge treatment, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

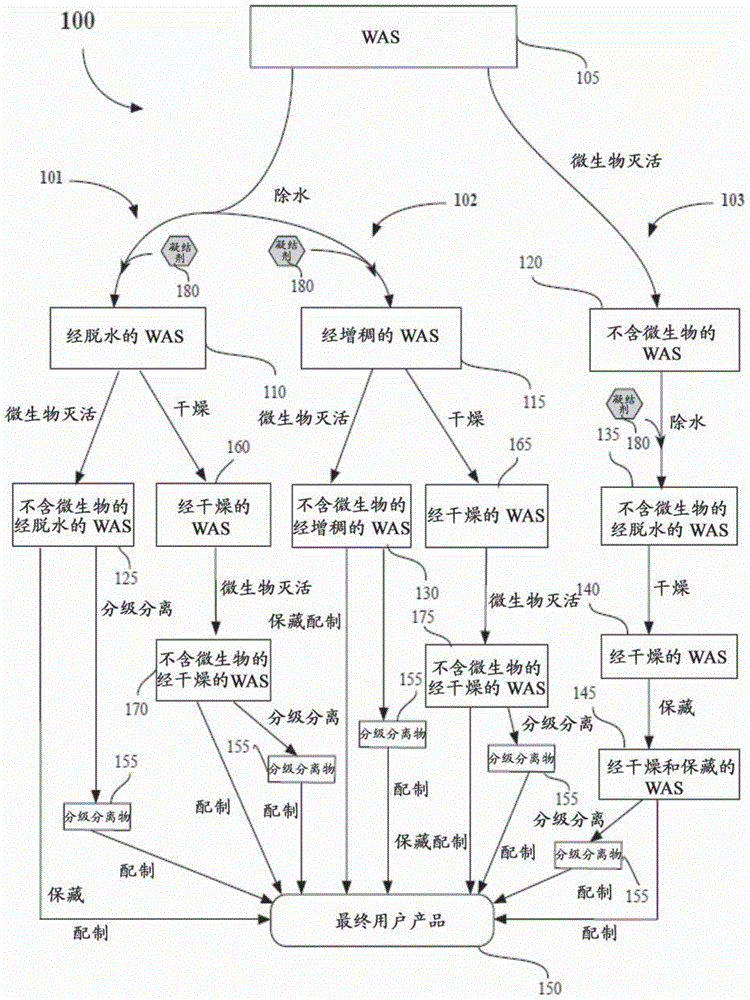

Method used

Image

Examples

Embodiment 1

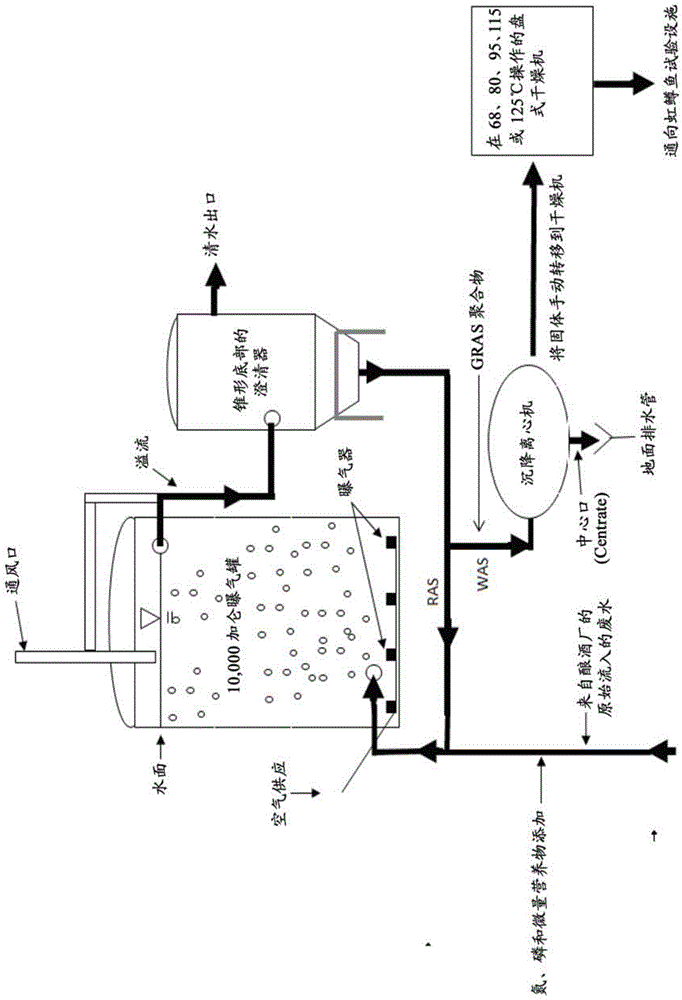

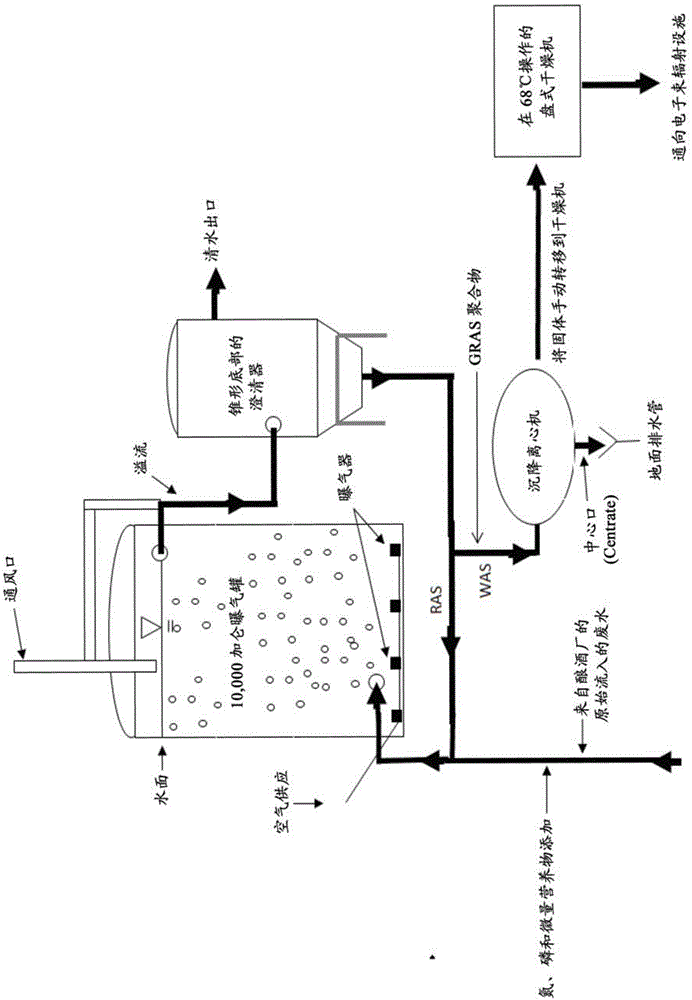

[0135] Example 1. Thermal Treatment of Waste Activated Sludge

[0136] A wastewater stream containing BOD, nutrients and dissolved oxygen is aerated in tanks or ponds to produce cellular biomass. This biomass is then separated from the bulk water in a clarifier, dissolved air flotation system, membrane filter, or other device, part of it is returned to the aerobic pond, and part of it is removed from the system as waste activated sludge. The waste activated sludge is then heated in a closed pressure vessel to a temperature of from about 121°C to about 155°C to produce commercially sterile waste activated sludge.

Embodiment 2

[0137] Example 2. Thermal Treatment of Waste Activated Sludge

[0138] Wastewater streams from beverage production plants, potato processing plants, corn processing plants, sugar processing plants, citrate production plants, yeast manufacturing plants, meat rendering plants or milk processing plants were treated as described in Example 1.

Embodiment 3

[0139] Example 3. Thermal Treatment of Waste Activated Sludge

[0140] Wastewater streams from beverage processing plants (such as beer breweries, wineries, palm oil mills or fruit juice factories) were treated as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com