Operating fluid container having a predetermined breaking point

A technology of working fluid and container, which is applied in the field of storage such as working fluid containers, which can solve the problems that the fracture effect cannot be achieved, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following description, the same reference numerals denote the same components or the same features, so descriptions about one component in one drawing are also applicable to other drawings, thereby avoiding repeated descriptions.

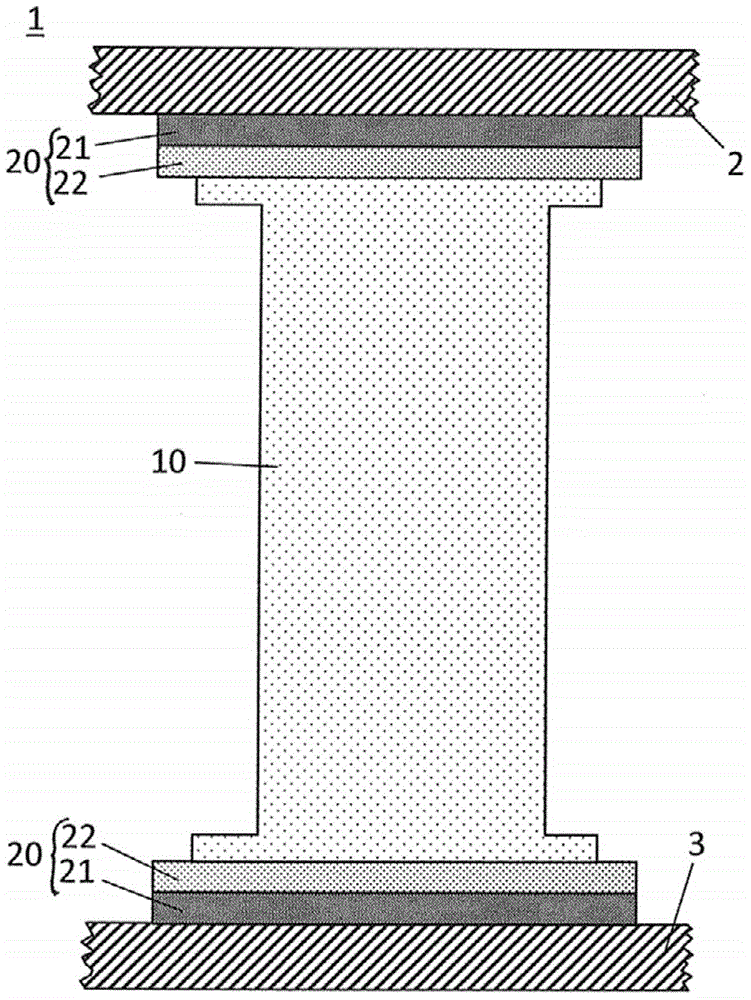

[0041] figure 1 A cross section of the operating fluid container 1 reinforced by the reinforcing element 10 is shown. The reinforcing element 10 is arranged between the two container walls 2 , 3 of the operating fluid container. In this case, the container wall 2 is designed as the upper housing 2 and the container wall 3 is designed as the lower housing 3 of the operating fluid container 1 .

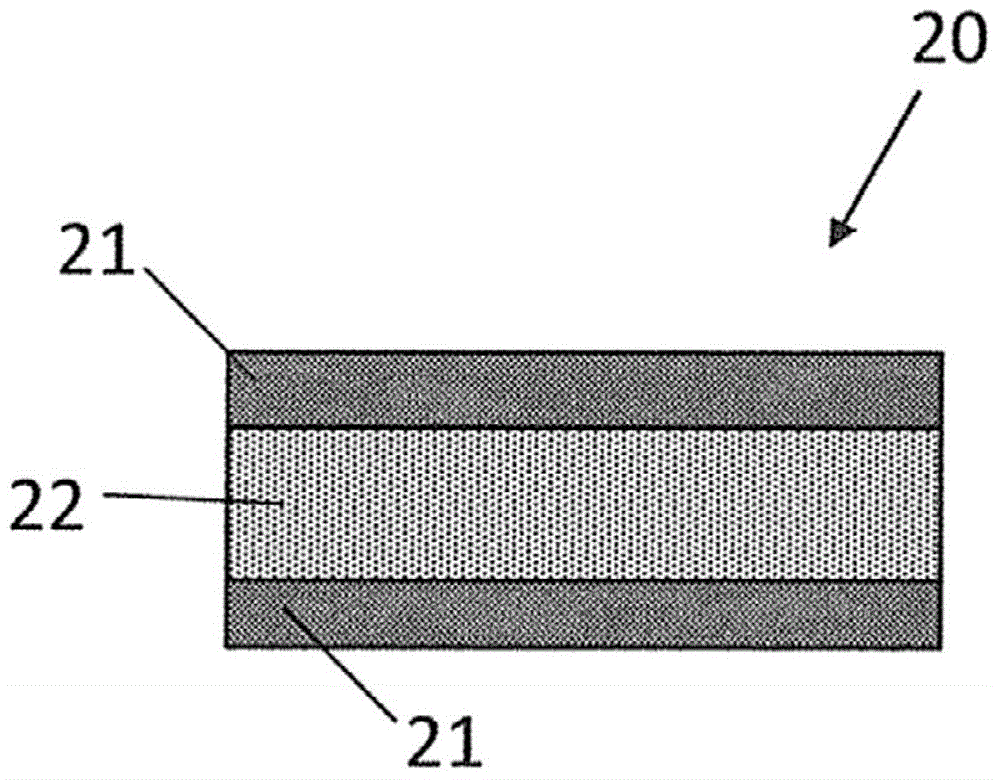

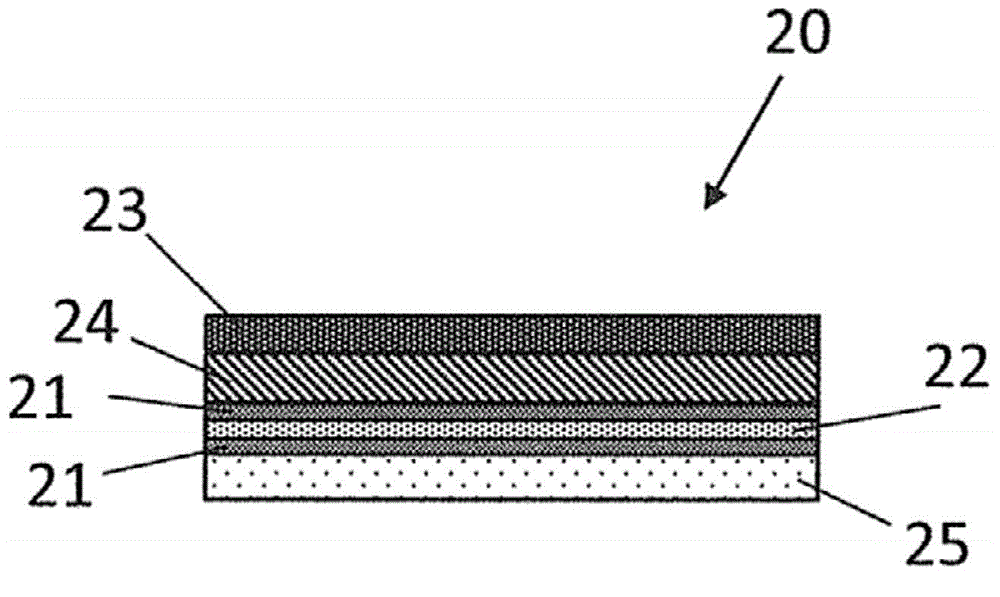

[0042] The respective connecting element 20 is arranged between the respective end region of the reinforcing element 10 and the upper housing 2 and the lower housing 3 . In the exemplary embodiment shown, each connecting element 20 comprises at least two material layers 21 , 22 connected to each other. The first material layer 21 may be a lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com