Rotary drives for construction machinery

A technology of slewing drive and construction machinery, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of increased friction loss, energy loss, and large friction loss effect, so as to increase the size and reduce the energy loss. , the effect of increasing the deceleration ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

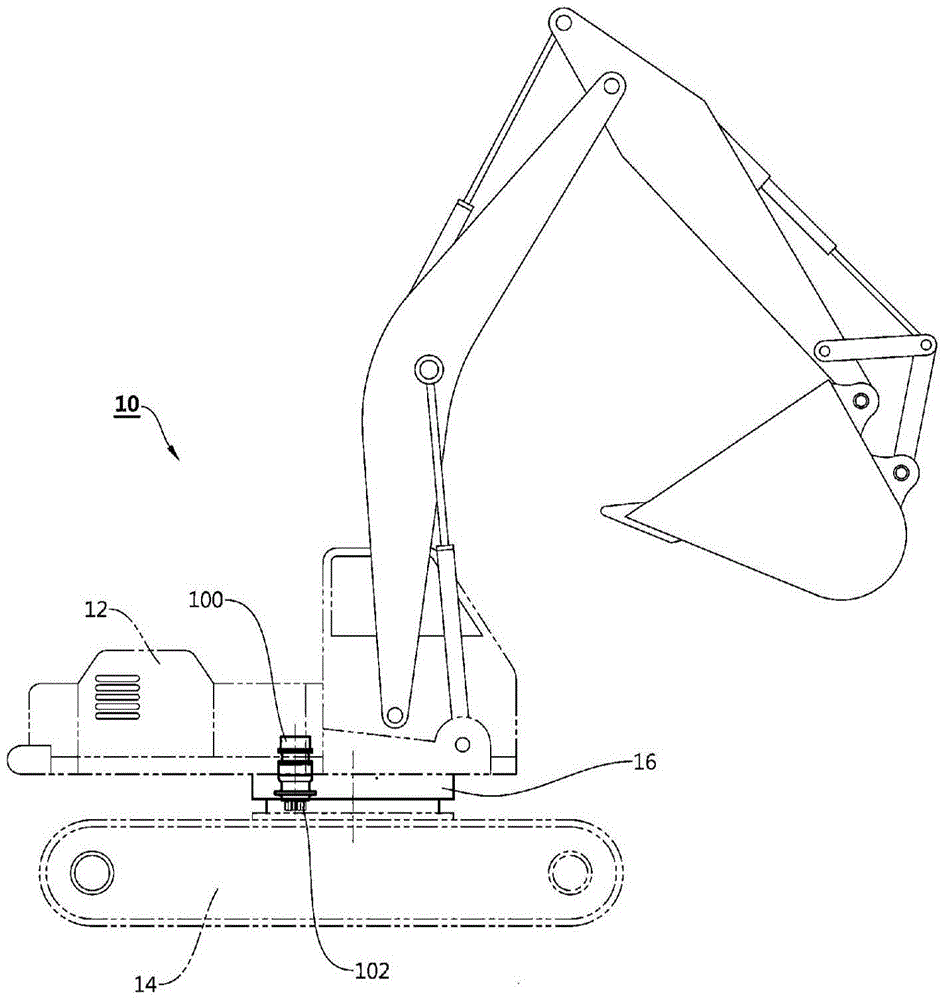

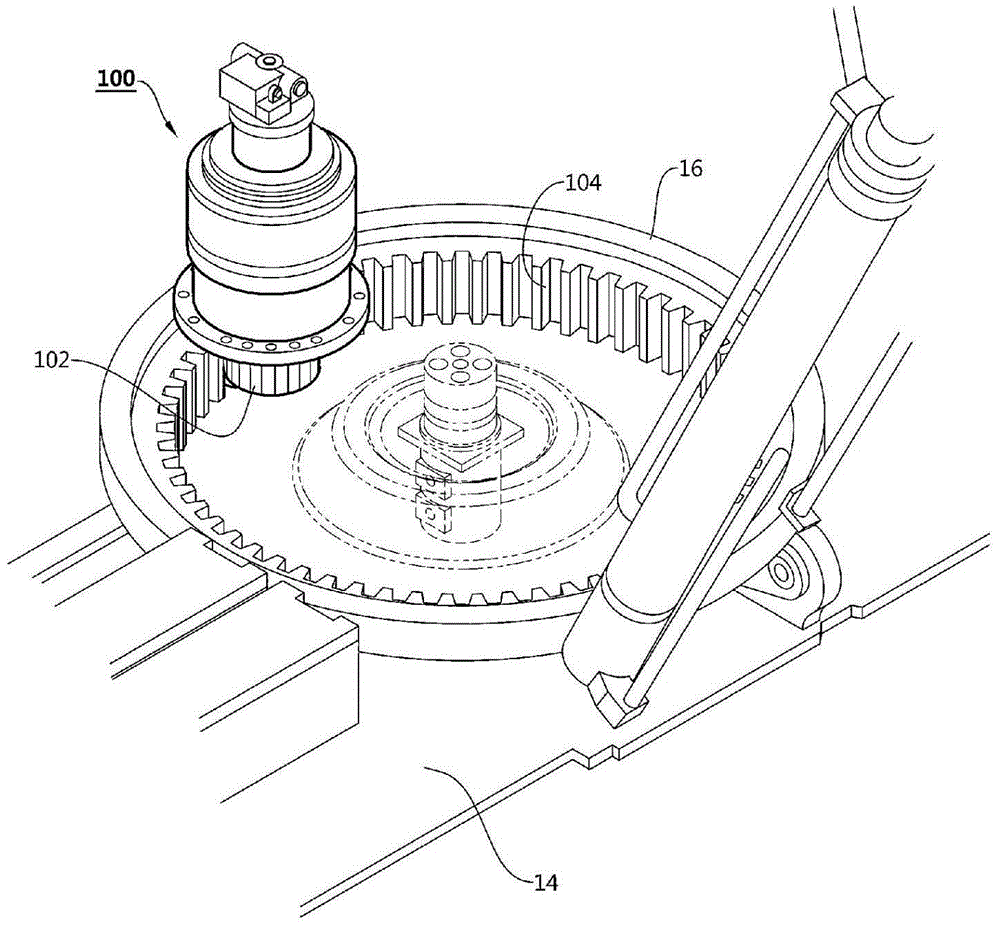

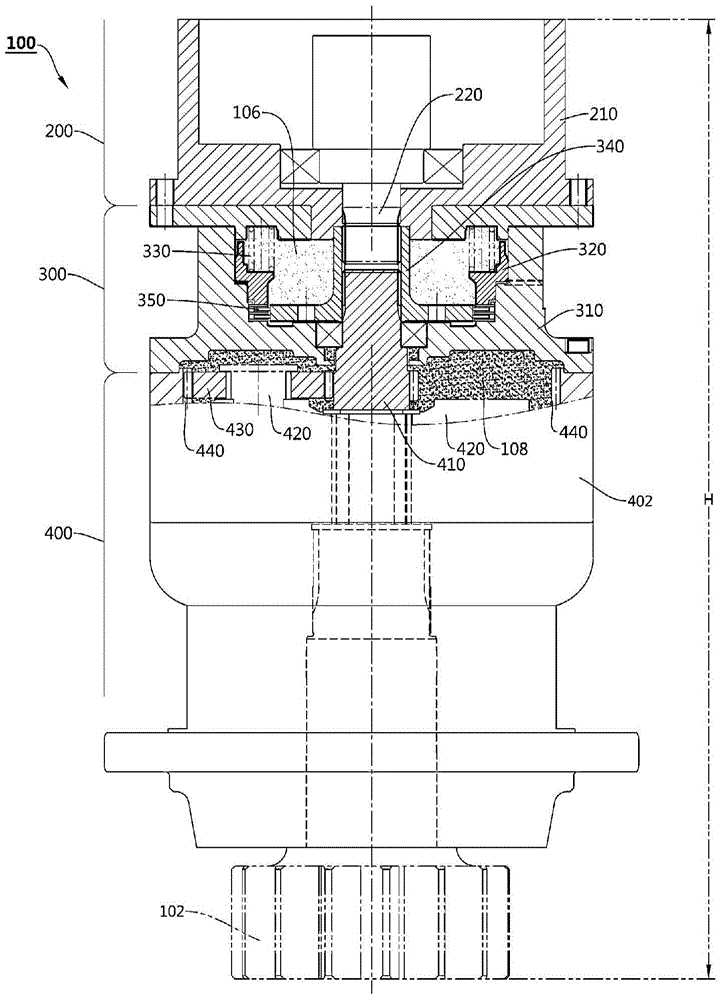

[0070] If referring to the following and attached Figure 1 With the detailed description of the embodiment, the advantages, features and methods for achieving the present invention will be clarified.

[0071] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The embodiments described below are exemplarily shown to help the understanding of the present invention, and it should be understood that the present invention can be variously modified and implemented differently from the embodiments described here. However, when describing the present invention, when it is judged that the specific description of related known functions or components may unnecessarily obscure the gist of the present invention, the detailed description and specific illustrations will be omitted. In addition, in order to facilitate the understanding of the invention, the drawings are not shown on an actual scale, and the sizes of some comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com