Motor driving device for motor-bicycle

A technology driven by electric bicycles and motors, applied in the direction of electric power devices, bicycles, power devices, etc., can solve the problems of weight increase, large noise of meshing parts, increase of outer diameter, etc., and achieve diameter and weight reduction, high deceleration ratio, noise Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

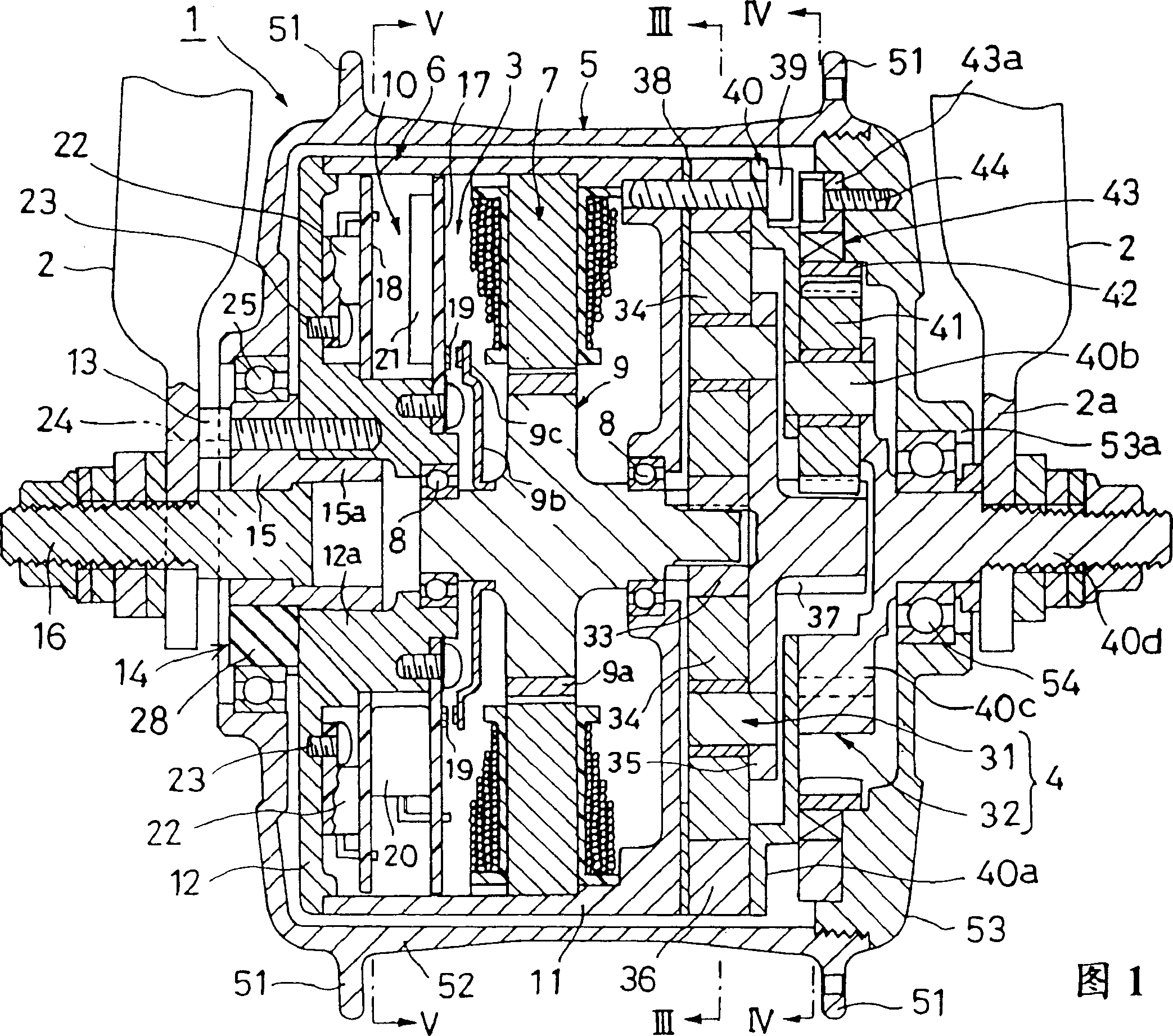

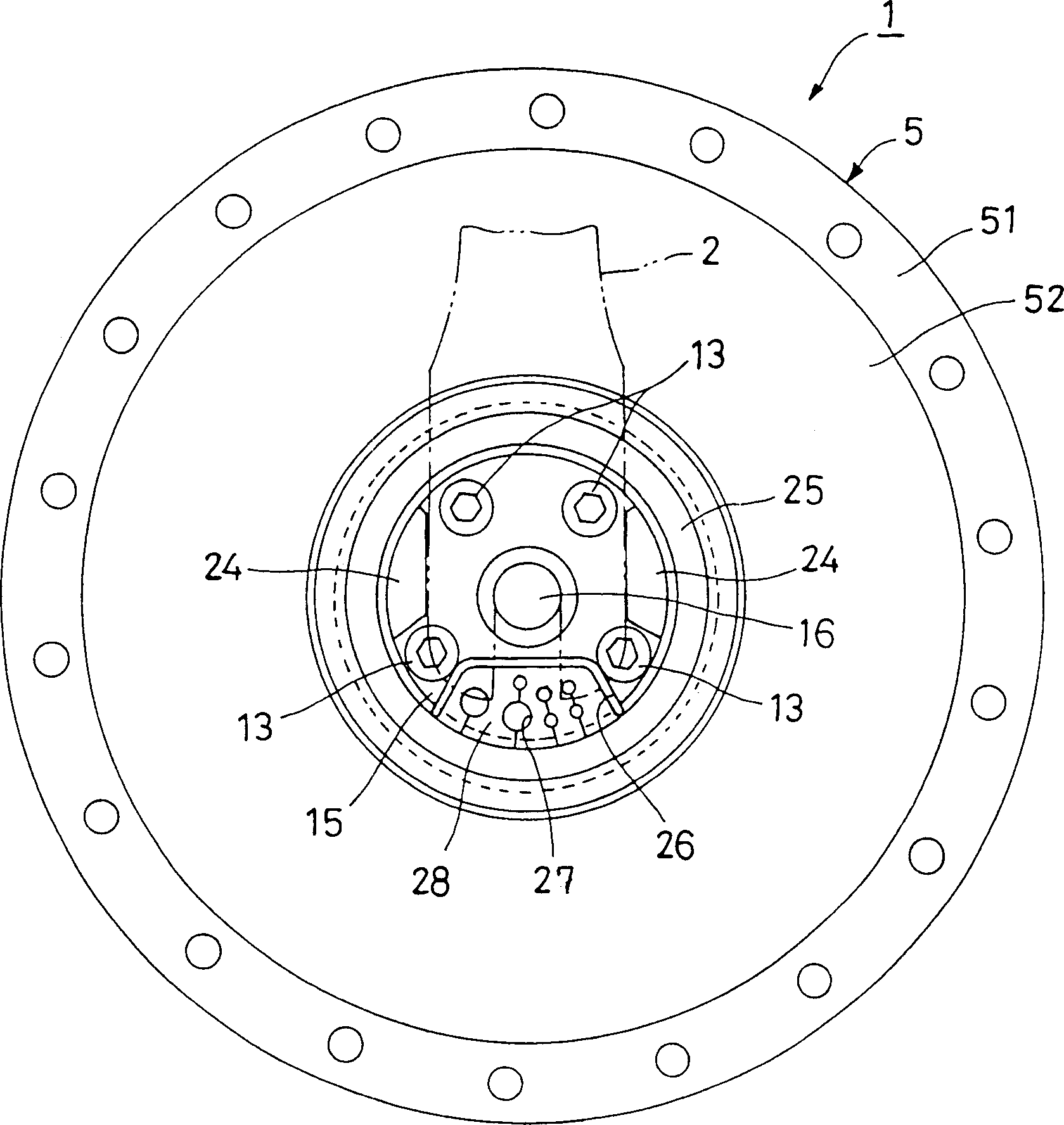

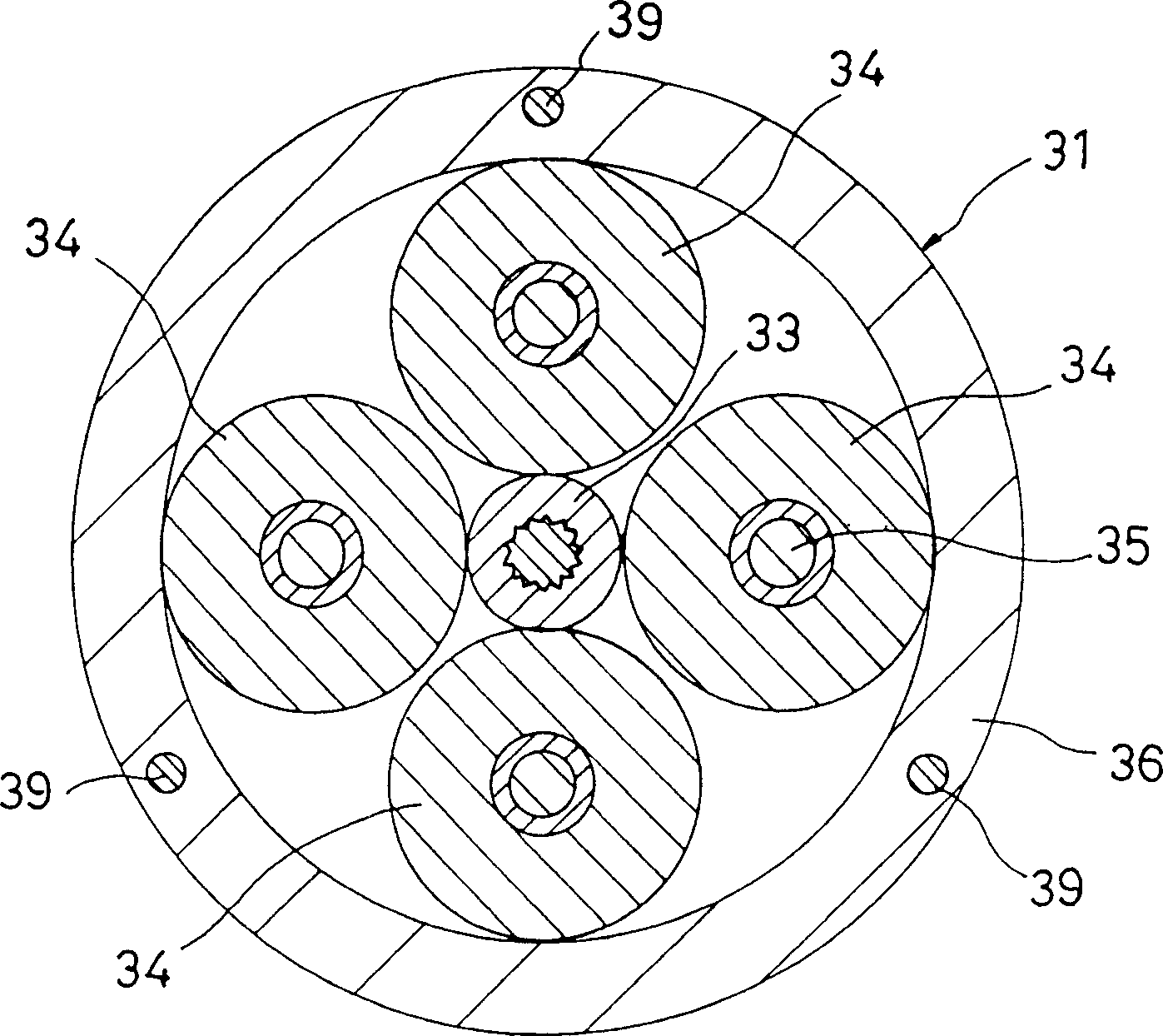

[0033] An embodiment of the electric bicycle motor drive device of the present invention will be described in detail below with reference to accompanying drawings 1 to 5.

[0034] Fig. 1 is a sectional view of the motor drive device of the electric bicycle of the present invention. figure 2 An end-on-side view of the motor of the motor drive is shown. image 3 It is a sectional view taken along line III-III of the planetary roller transmission shown in FIG. 1 . Figure 4 It is a sectional view taken along line IV-IV of the planetary gear transmission shown in FIG. 1 . Figure 5 is a view of a substrate on which capacitors are mounted, seen along the section line V-V in FIG. 1 .

[0035] In the drawings, the motor driving device of the electric bicycle of this embodiment is represented by reference numeral 1 . The motor drive 1 is located in the axial part of the front wheel and is connected to the front fork indicated by reference numeral 2 in FIG. 1 . In the structure of ...

no. 2 example

[0066] The motor driving device of the electric bicycle of the present invention may adopt a structure arranged in the axial portion of the rear wheel. Such an embodiment will be described in detail below with reference to FIG. 6 .

[0067] Figure 6 is a cross-sectional view of such an embodiment. In FIG. 6, the same or equivalent components as those described with reference to FIGS. 1 to 4 have the same or corresponding reference numerals, and thus will not be described again.

[0068] The structure of the motor driving device 61 shown in FIG. 6 is partially modified on the basis of the front wheel motor driving device in the first embodiment. Two modifications made will be described below.

[0069] The first point of modification concerns a part of the device where the device is attached to the vehicle body frame 62 . That is, because the distance between the two end frames 63 for supporting the rear wheel of the bicycle is greater than the distance between the end frames...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com