A multi-strip noodle rubbing machine with adjustable noodle thickness

A kind of rubbing machine and thickness technology, which is applied in the direction of dough forming machinery or equipment, mechanical equipment, belts/chains/gears, etc. The effect of improving the rubbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

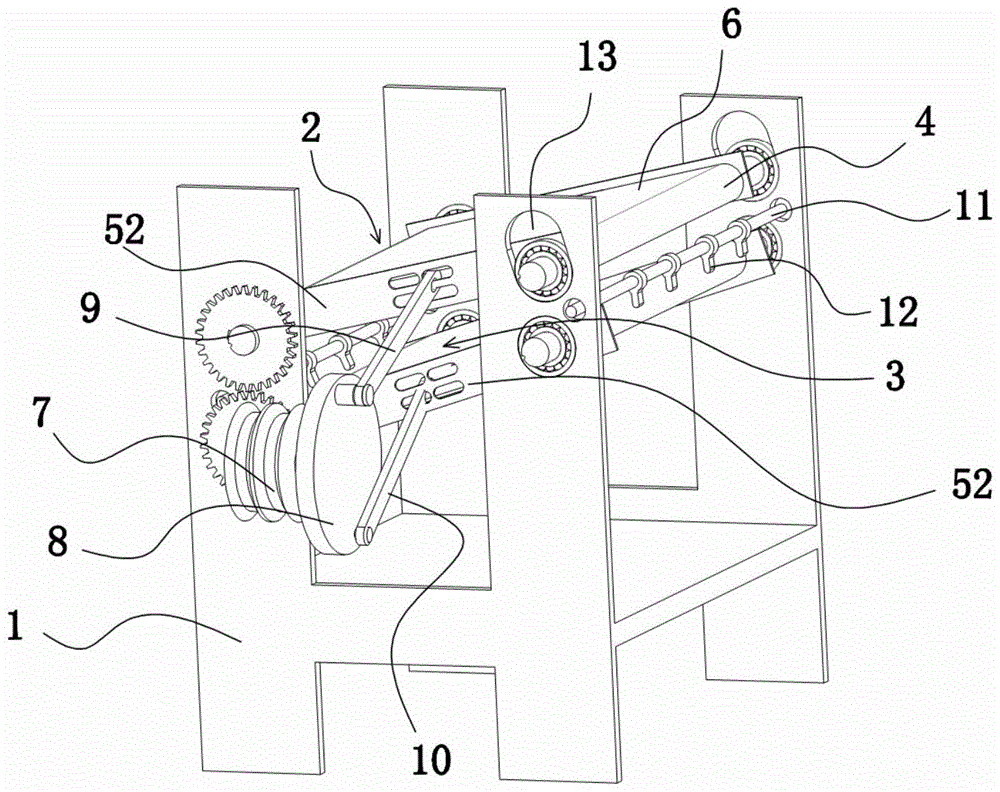

[0028] As shown in the figure, the twisting machine includes a frame body 1. The frame body 1 is provided with a conveyor belt 2 and a conveyor belt 2 3 located below the conveyor belt 1. There is a 0.5-2cm gap between the conveyor belt 2 and the conveyor belt 3 , Conveyor 1 2 and Conveyor 2 3 are driven by the drive roller 4 to convey the semi-finished rough strip located between the gaps. Conveyor 1 and Conveyor 2 are simultaneously driven by a driving mechanism to make reverse reciprocating motion in the direction perpendicular to the conveying direction to knead. The thick strips conveyed between the gaps, that is, conveyor belt one and conveyor belt two always move in opposite directions.

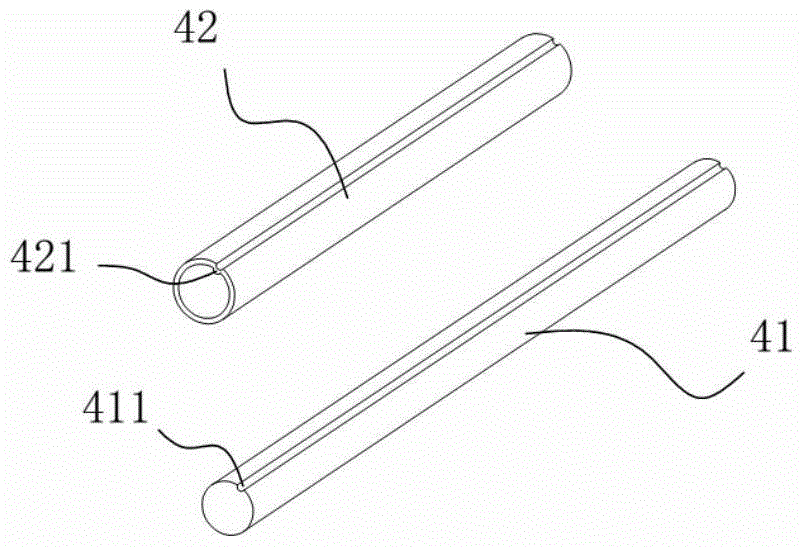

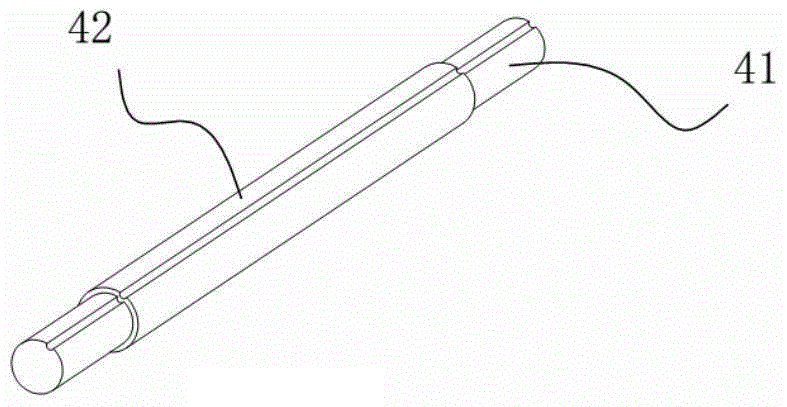

[0029] Further, the first conveyor belt and the second conveyor belt both include a support member 5 and a closed conveyor belt. The front and rear ends of the support member are respectively provided with shaft holes 51. The shaft holes 51 are rotationally matched with the driving roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com