a textile bobbin

A yarn bobbin and protection mechanism technology, which is applied in the field of textile yarn bobbin, can solve the problems of side plate and side plate collision, yarn cutting, spinning slippage, etc., so as to prevent yarn from being too loose, excessive load, and yarn The effect of broken lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

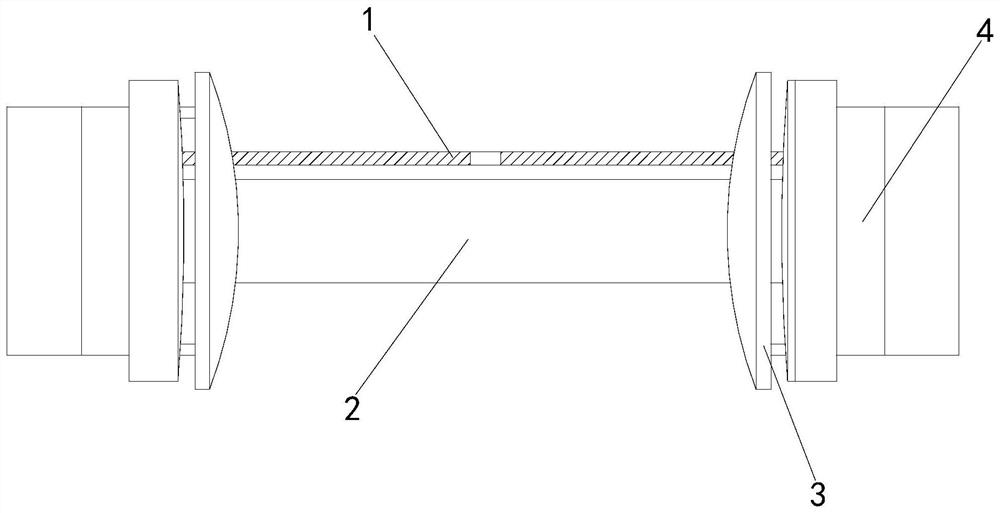

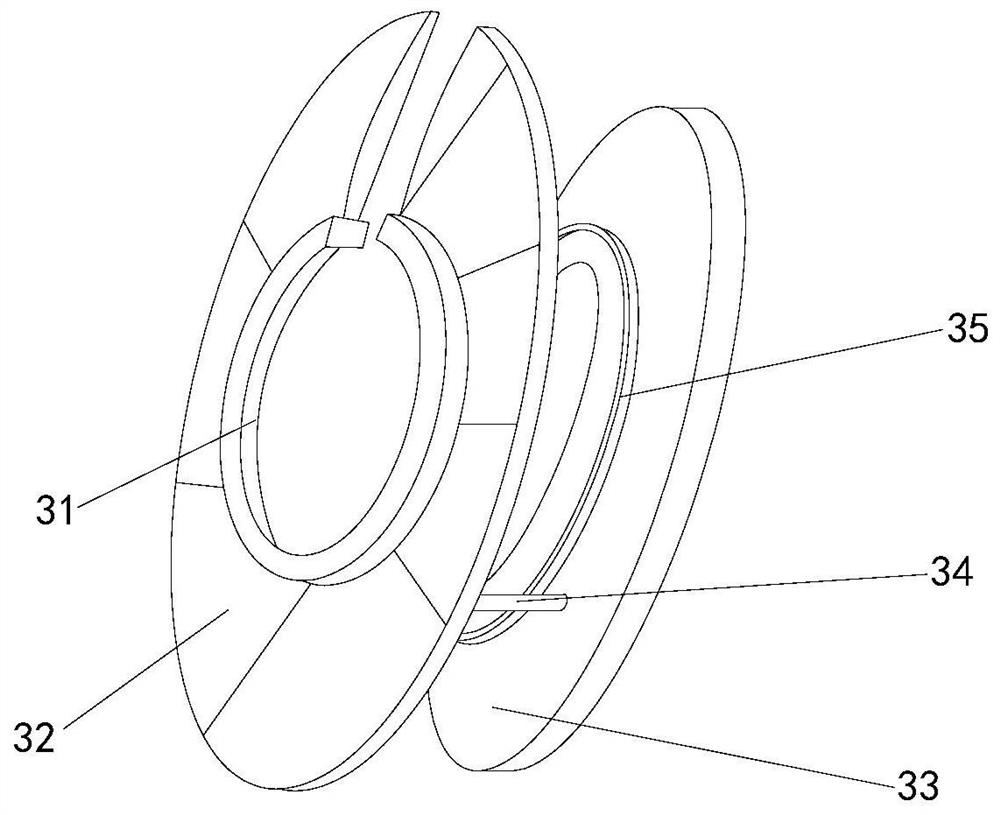

[0025] Such as Figure 1-Figure 5 Shown:

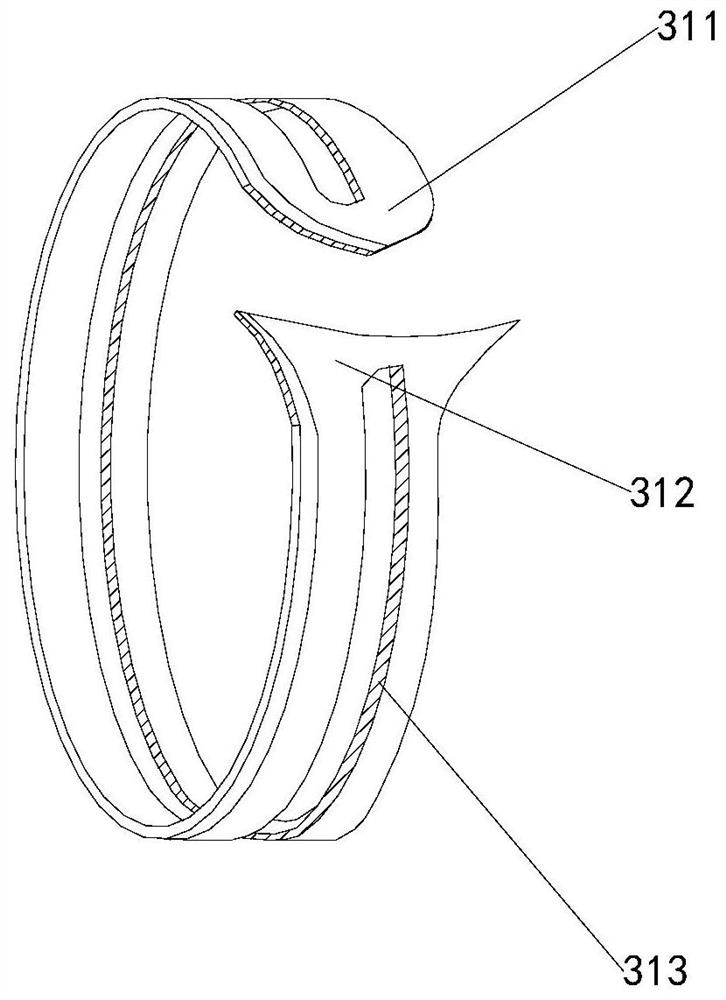

[0026] The present invention is a textile yarn bobbin, the structure of which includes a moving mechanism 1, a winding rod 2, a protection mechanism 3, and a rotating block 4. The winding rod 2 is embedded and installed inside the protection mechanism 3, and the rotating block 4 is fitted On the outside of the protective mechanism 3, the moving mechanism 1 and the winding rod 2 are parallel to each other, and the protective mechanism 3 is installed on both ends of the moving mechanism 1. 33. A connecting rod 34 and a sliding ring 35 are formed. The sliding mechanism 31 is embedded and installed on the left side of the protective disk 32. The sliding ring 35 is welded on the left side of the fixed disk 33. Both ends of the connecting rod 34 are welded on the The right side of the protective disk 32 and the left side of the fixed disk 33, the fixed disk 33 is attached to the inner side of the rotating block 4, the connecting rod 34 is ...

Embodiment 2

[0033] Such as Figure 6-Figure 8 Shown:

[0034]Wherein, the blocking mechanism 14 is provided with a gear rod 141, a rotating block 142, a spring 143, a fixing mechanism 144, and a gap block 145, and the gear rod 141 and the rotating block 142 are engaged with each other, and the gear rod 141 is attached to the spring 143. At the left end, the fixing mechanism 144 is embedded in the right end of the spring 143, the gap block 145 is attached to the right end of the fixing mechanism 144, the gap block 145 is installed at the lower end of the moving block 11, and the rotating block 142 is provided with two symmetrical Distributed on both sides of the spring 143, by turning the rotating block 142 to make the gear lever 141 squeeze the spring 143, it has the effect of adjusting the size of the yarn gap and preventing the yarn from being too loose.

[0035] Wherein, the fixing mechanism 144 is composed of a force-bearing block a1, a rubber rod a2, a compression block a3, a spheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com