Steel ball type automobile steering intermediate shaft steel ball retainer

A cage and intermediate shaft technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of easy wear of cages, increased material costs, and reduced cleanliness of raceways, so as to improve working conditions and prolong work. Life and contact area reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments are described in detail in conjunction with the accompanying drawings,

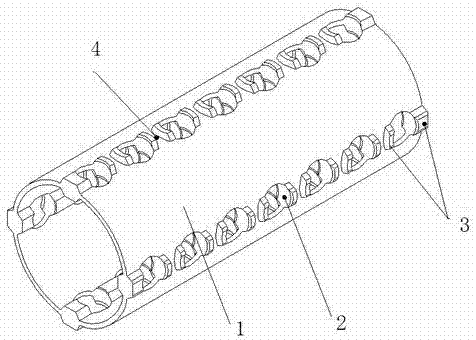

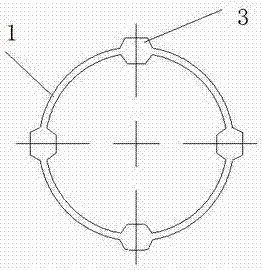

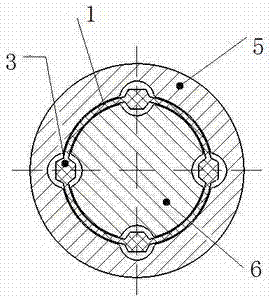

[0011] A steel ball type automobile steering intermediate shaft steel ball cage, which includes a ball bowl 2, a plurality of parallel ball bowls are arranged on the frame body 1 of the steel ball type automobile steering intermediate shaft steel ball cage, and each ball Both sides of the bowl are provided with irregular polygonal ribs 3, and an oil storage tank 4 is left between adjacent polygonal ribs; the polygonal ribs protrude from the surface of the steel ball cage; the polygonal ribs The height of the rib protruding from the surface of the steel ball cage can be selected as 1.75-4 mm, and 2 mm is the best.

[0012] The present invention utilizes the presence of irregular polygonal reinforcing ribs to increase the space gap between the reinforcing ribs and the peach-shaped raceway formed by the sleeve shaft 6 and the sleeve 5, thus eliminating the problems caused by the lack of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com