Portable dry-wet dual-purpose smoothbore pipe and line bore pipe inner surface wiping and cleaning device

A wet and dry dual-use, cleaning device technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as power supply dependence, inability to spray, and inability to quantitatively supply liquid, and achieves reduction in rotational speed and torque. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

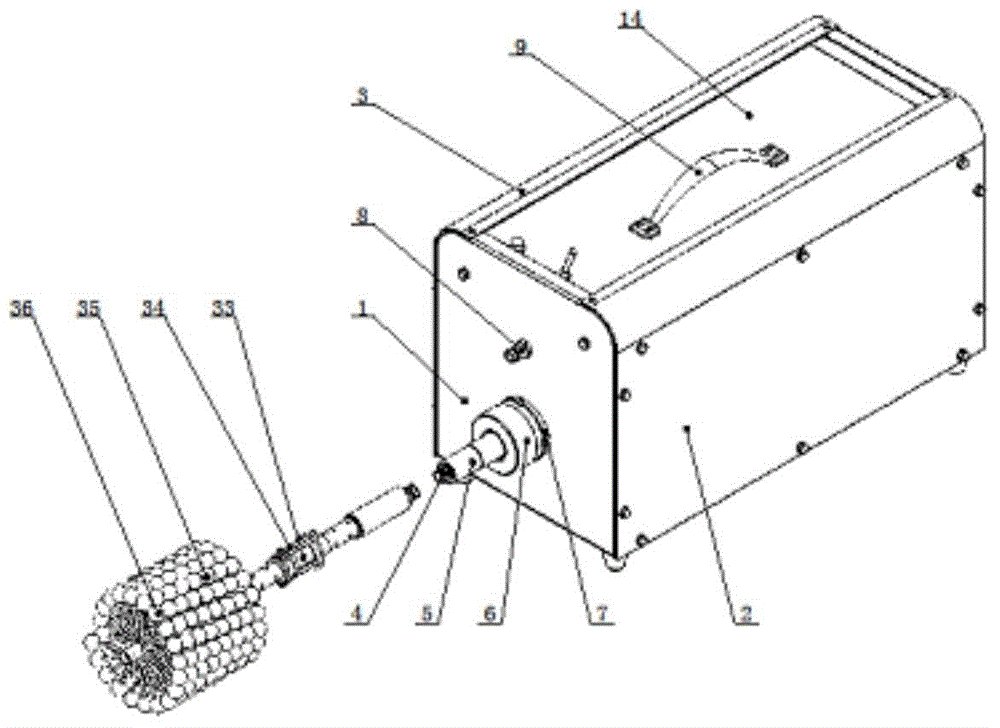

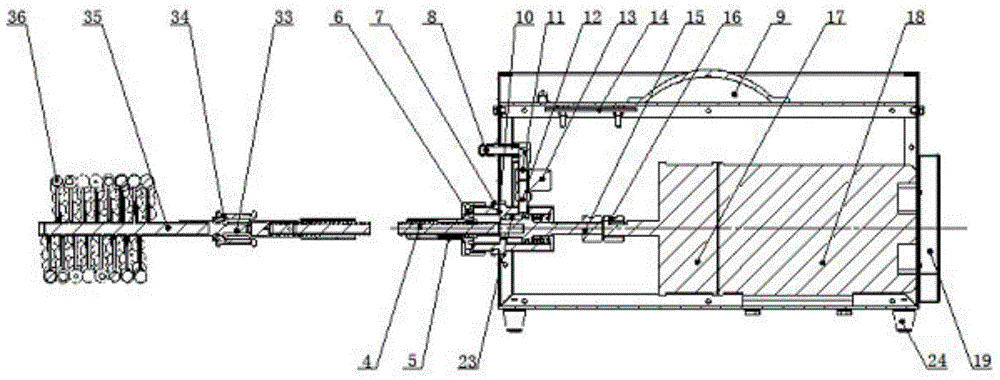

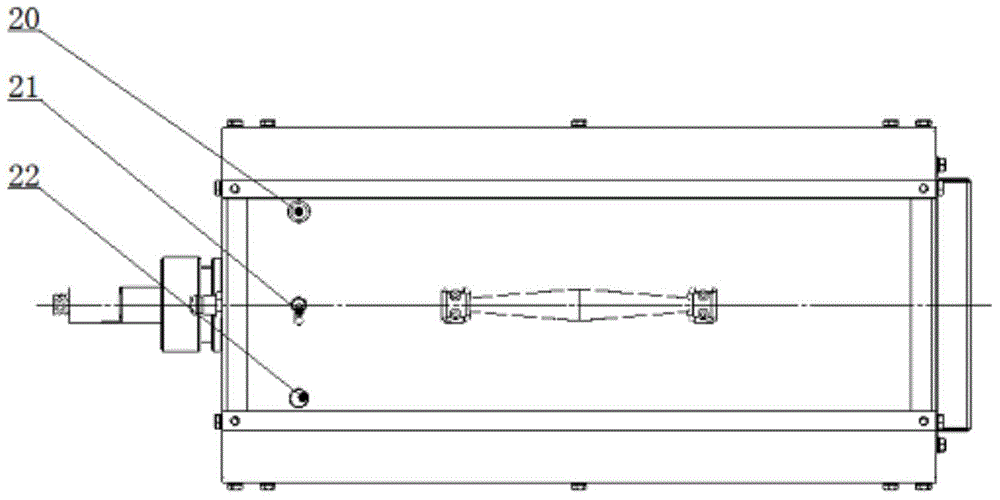

[0029] The connection relationship of each component in the portable dry-wet dual-purpose smoothbore tube and the internal surface cleaning device of the rifled tube is as follows: the drive motor 18 and the reducer 17 are installed at the bottom of the chassis 1, and the reducer shaft is connected to the output shaft 15 through the coupling 16, The output shaft 15 is installed in the bearing seat 10, and the bearing seat is locked on the front end of the cabinet 1 with the bearing seat lock nut 7, and the flexible shaft 4 and the sheath 5 are locked in the bearing seat 10 with the flexible shaft lock nut 6.

[0030] The top of the bearing seat is installed in sequence: the bearing seat intake pipe 12, the solenoid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com