Traction trolley driven transport hopper

A technology for pulling trolleys and hoppers, applied to supply devices, manufacturing tools, etc., can solve the problems of difficult construction, low production efficiency, and high equipment costs, and achieve the goal of reducing equipment costs and construction difficulties, improving production efficiency, and improving transportation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

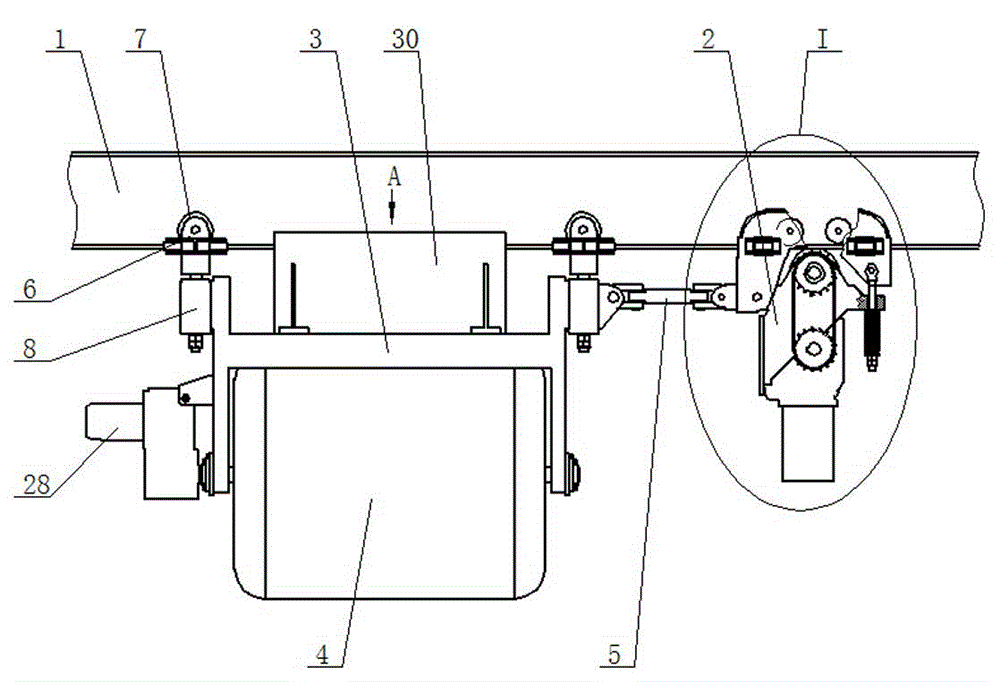

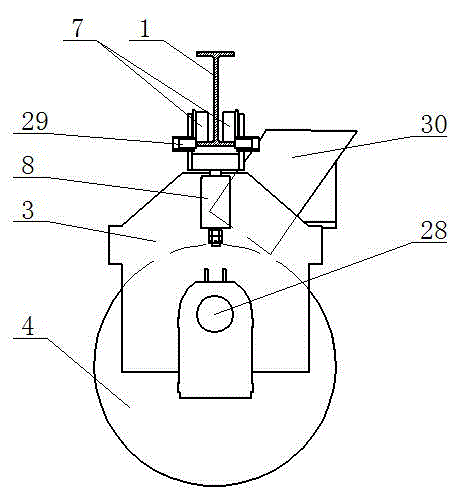

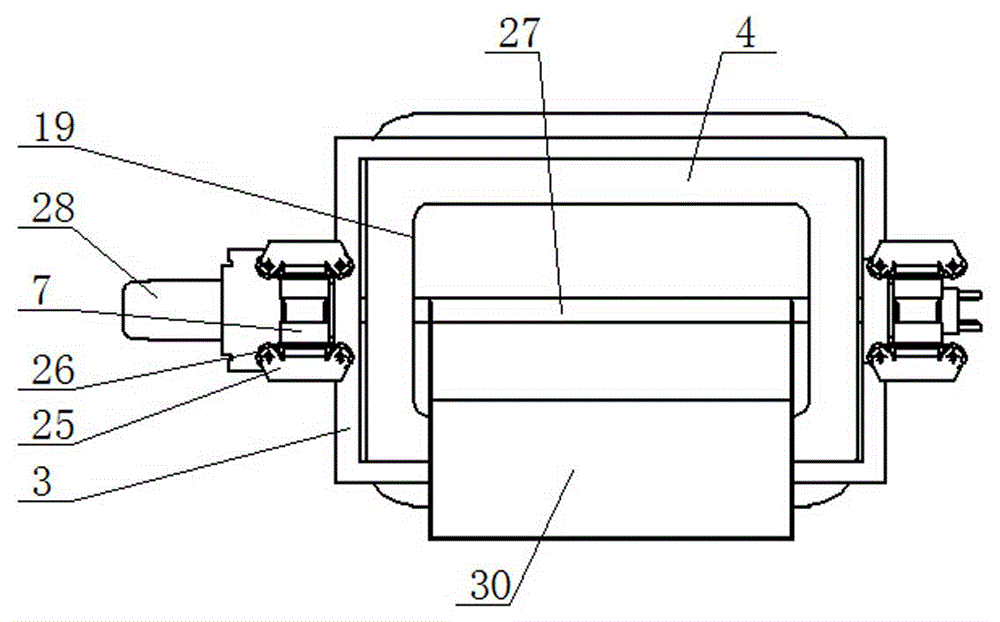

[0014] A transport hopper driven by a traction trolley according to the present invention comprises a track 1, a traction trolley 2 is installed on the track 1, a hopper suspension wheel set 6 is installed on the track 1, and the driven suspension wheel 7 in the hopper suspension wheel set 6 and the track 1 Cooperate, the hopper hanging wheel group 6 is connected with the hopper frame 3 through the wheel group longitudinal rotation assembly 8, the hopper hanging wheel group 6 can rotate relative to the vertical direction of the hopper frame 3, the hopper frame 3 is installed with the hopper 4, and the top of the hopper 4 is provided with a feed inlet 19. A discharge device is installed on the hopper 4, and a connecting rod 5 is set between the traction trolley 2 and the hopper frame 3. One end of the connecting rod 5 is connected to the traction trolley 2 through a universal joint, and the other end of the connecting rod 5 is connected to the hopper frame through a universal joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com