Pipe pile mold

A tubular pile formwork and tubular technology, applied in the mold and other directions, can solve the problems of inconvenient structure limitation, inability to match the structure with revetment, lack of new pipe pile revetment, etc., and achieve the effects of convenient removal of finished products, quality assurance, and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

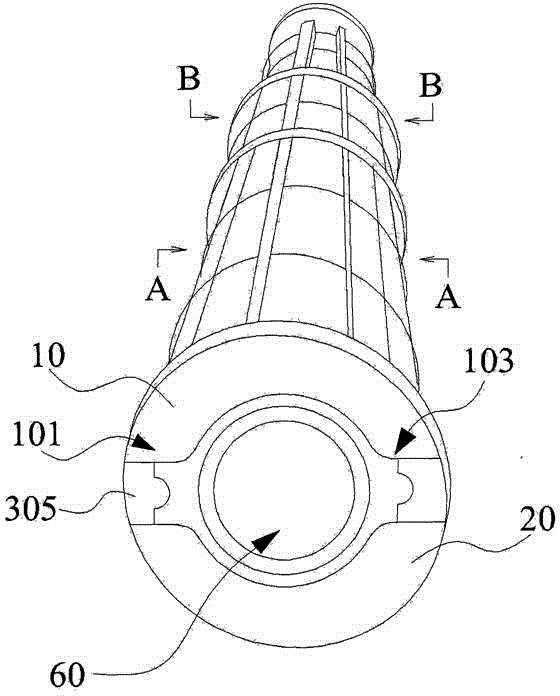

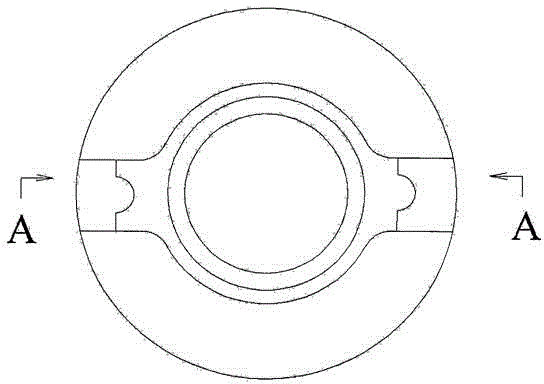

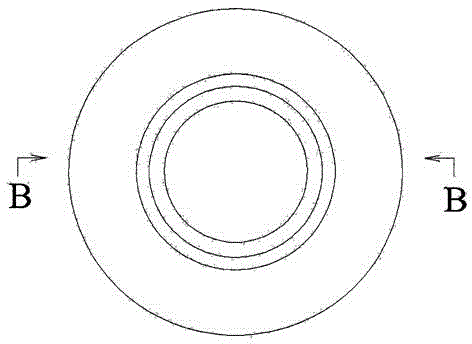

[0020] Figure 1 to Figure 7 A pipe pile form according to one embodiment of the present invention is schematically shown. As shown in the figure, the pipe pile form includes a first semicircular pipe 10 and a second semicircular pipe 20, and the first semicircular pipe 10 and the second semicircular pipe 20 can be spliced into a pipe pile formwork body of a hollow pipe pile.

[0021] The first semicircular tube 10 is concave and forms an arc surface in the concave portion. The first semicircular tube 10 and the second semicircular tube 20 are spliced together to form a pile formwork body, and a through hole is formed at the center of the body, and the through hole is defined as the feeding hole 60 .

[0022] The second semicircular tube 20 is concave, and a first groove 101 and a second groove 103 are formed on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com