An incomplete gear periodic meshing steering device

A complete gear and steering device technology, applied in the mechanical field, can solve problems such as limited adjustment range and inability to adjust the motion parameters of the connecting rod steering mechanism, and achieve the effect of reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

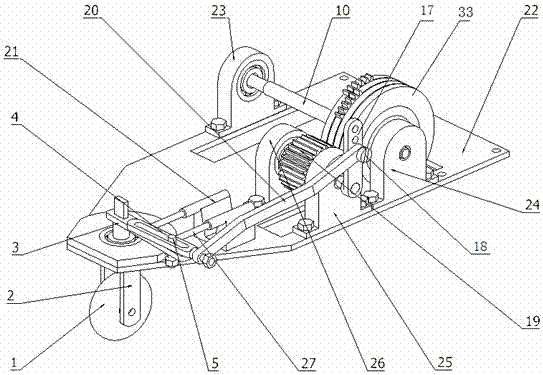

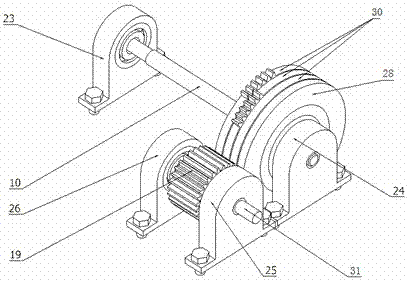

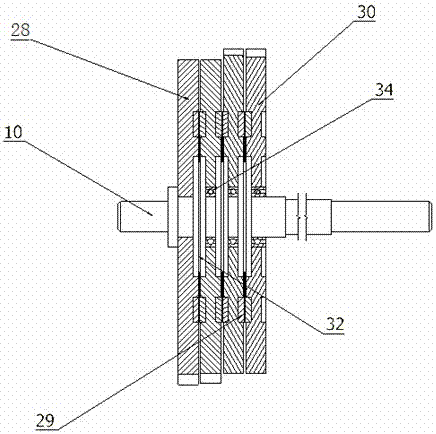

[0027] Embodiment 1: as Figure 1-5 As shown, the incomplete gear periodic meshing steering device includes steering wheel 1, front fork 2, rocker I3, rocker II4, slider 5, shaft I10, crank 17, pin 18, spur gear IV19, connecting rod 20, Limiting part 21, vehicle chassis 22, bearing seat III 23, bearing seat IV 24, bearing seat V 25, bearing seat VI 26, guide rod 27, shaft IV 31, variable number of teeth incomplete gear mechanism 33; The fork 2 is connected, and the front fork 2 is installed on the front end of the chassis 22 to form a rotating pair with the chassis 22. The rocker I3 is fixedly connected to the front fork 2, and the slider 5 can be fixedly connected to the groove of the rocker I3 according to different requirements. position, two guide rods 27 are installed on the rocker II4, and the two guide rods 27 are connected with two stoppers 21 to form a moving pair, and the stoppers 21 are fixed on the chassis 22; one end of the rocker II4 is connected to the connectin...

Embodiment 2

[0032] Embodiment 2: The device structure of this embodiment is the same as that of Embodiment 1, the difference is that the number of teeth of each incomplete gear in the variable number of incomplete gear mechanism is 7, and the incomplete gear on the right side of the variable number of teeth incomplete gear mechanism is rotated. Gear II 30, so that the incomplete gear mechanism with variable number of teeth is divided into 2 tooth areas, each tooth area has 14 teeth, and the angle between the centerlines of adjacent tooth intervals is 180 degrees. Through this incomplete gear mechanism with variable number of teeth 33, it can realize The steering range of the steering wheel 1 is changed between -45° (left direction) and 45° (right direction).

Embodiment 3

[0033] Embodiment 3: as Figure 6 As shown, the incomplete gear periodic meshing steering device includes steering wheel 1, front fork 2, rocker I3, rocker II4, slider 5, cylindrical gear I6, motor 7, cylindrical gear II8, driving wheel 9, shaft I10 , Cylindrical gear III11, shaft II12, bearing housing I13, bearing housing II14, shaft III15, driven wheel 16, crank 17, pin 18, cylindrical gear IV19, connecting rod 20, limiter 21, chassis 22, bearing housing III23, Bearing seat Ⅳ24, bearing seat Ⅴ25, bearing seat Ⅵ26, guide rod 27, shaft Ⅳ31, incomplete gear mechanism with variable number of teeth 33; steering wheel 1 is connected with front fork 2 through hinge pin shaft, and front fork 2 is installed on the chassis The front end of 22 and the chassis 22 form a rotating pair, the rocker I3 is fixedly connected to the front fork 2, the slider 5 can be fixedly connected to different positions on the groove of the rocker I3 according to requirements, and two guide rods 27 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com