Water purification process

A water purification and process technology, applied in the direction of osmosis/dialysis water/sewage treatment, etc., can solve the problems of fast pollution of the purification membrane group, short service life of the purification membrane group, and high probability of fouling, so as to prolong the service life and reduce the pollution. Pollution probability and effect of reducing chemical cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

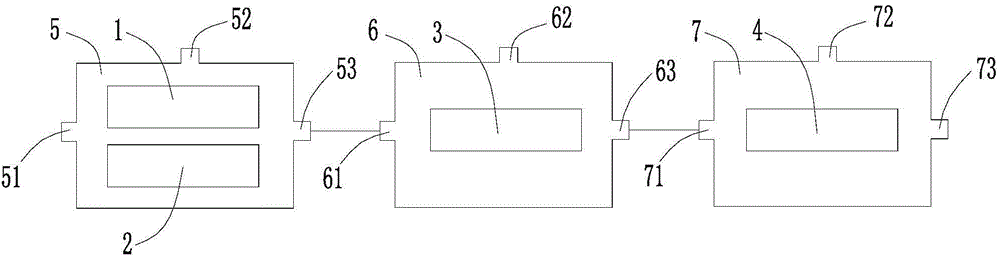

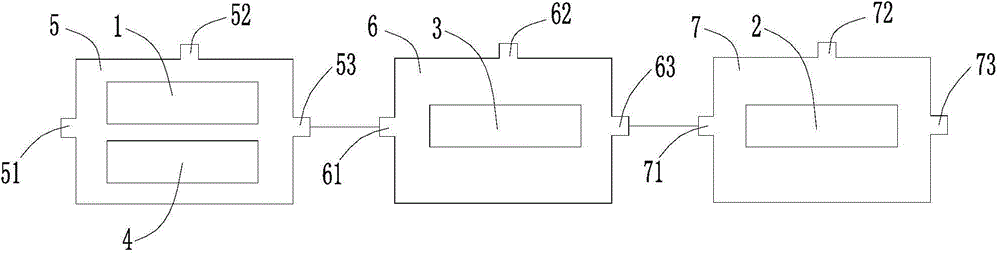

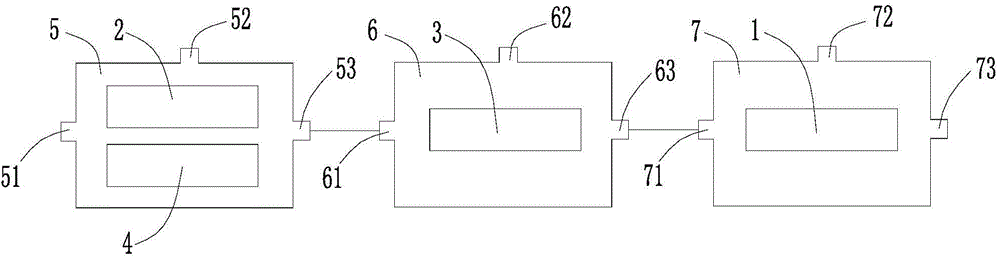

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] see Figure 1-3 As shown, the above-mentioned water purification process purifies the water body through a purification device. The purification device includes a water inlet for passing into the water body, a purification membrane group for purifying the water body, a water production port for discharging clean water, and a water outlet for discharging Concentrated water outlet, the water purification process includes the following steps:

[0025] (1) Prepare four purification devices and assign them to form the front purification device group 5, the middle purification device group 6, and the rear purification device group 7. The front purification device group 5, the middle purification device group 6 and the rear purification device group 7 to form a purification system.

[0026] When the purification system was in the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com