Meta-aromatic poly-1,3,4-oxadiazole and fibrid containing it

A technology for precipitating fibers and oxadiazoles, applied in the field of meta-aromatic poly-1,3,4-oxadiazoles and its preparation, which can solve the problems of poor temperature resistance and flame retardancy, complicated process procedures, and poor test repeatability and other problems, to achieve the effect of uniform size, good dispersion and good fiber dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

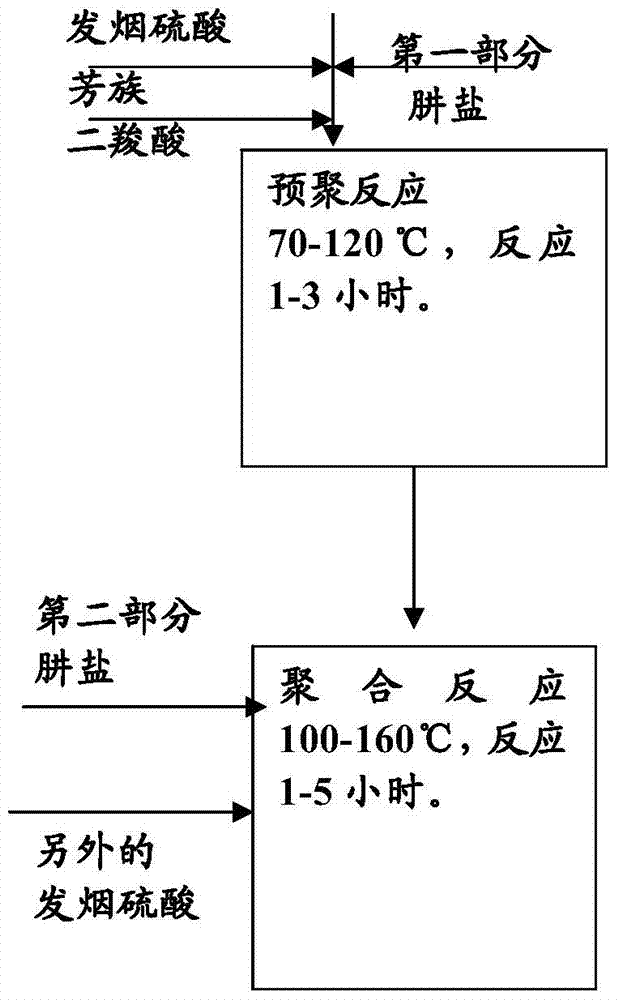

[0091] Example 1: Preparation of meta-POD

[0092] First add 7 parts of oleum to the reaction kettle through the metering device, then mix 1 part of IPA and 0.7 parts of HS and add them together to the reaction kettle. After stirring evenly, program the temperature to 100°C and the stirring speed to 100rpm. When the stirring torque reaches 20Nm, the online viscosity at this time is 35Pa·s, and this stage is the pre-polymerization reaction. Turn on the tail gas absorption device, add 3 parts of oleum and 0.3 parts of HS at the same time to continue the reaction, and program the temperature to 120°C. Stop stirring when the stirring torque reaches 50Nm, and the online viscosity at this time is 81Pa·s, and this stage is a polymerization reaction. The concentration of the finally obtained polymer stock solution was 6%. Drop a certain amount of polymer solution into water, filter the coagulated and precipitated polymer, wash it with a large amount of water several times to become ...

Embodiment 2

[0093] Example 2: Preparation of meta-POD

[0094] First add 5 parts of oleum to the reaction kettle through the metering device, then mix 1 part of IPA and 0.5 parts of HS and add them to the reaction kettle together. After stirring evenly, program the temperature to 70°C, and the stirring speed is 100rpm. When the stirring torque reaches 30Nm, the online viscosity at this time is 22Pa·s, and this stage is the pre-polymerization reaction. Turn on the tail gas absorption device, add 3 parts of oleum and 0.3 parts of HS at the same time to continue the reaction, and program the temperature to 120°C. Stop stirring when the stirring torque reaches 50Nm, and the online viscosity at this time is 65Pa·s, and this stage is a polymerization reaction. The concentration of the finally obtained polymer stock solution was 5%. Drop a certain amount of polymer solution into water, filter the coagulated and precipitated polymer, wash it with a large amount of water several times to become ...

Embodiment 3

[0095] Embodiment 3: the preparation of meta-position POD

[0096] First add 10 parts of oleum to the reaction kettle through the metering device, then mix 1 part of IPA and 1 part of HS and add them to the reaction kettle together. After stirring evenly, program the temperature to 100°C and the stirring speed to 100rpm. When the stirring torque reaches 25Nm, the online viscosity at this time is 45Pa·s, and this stage is the pre-polymerization reaction. Turn on the tail gas absorption device, add 5 parts of oleum and 0.5 parts of HS to continue the reaction, and program the temperature to 120 °C. Stop stirring when the stirring torque reaches 65Nm, and the online viscosity at this moment is 117Pa·s, and this stage is a polymerization reaction. The concentration of the finally obtained polymer stock solution was 8%. Drop a certain amount of polymer solution into water, filter the coagulated and precipitated polymer, wash it with a large amount of water several times to become...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

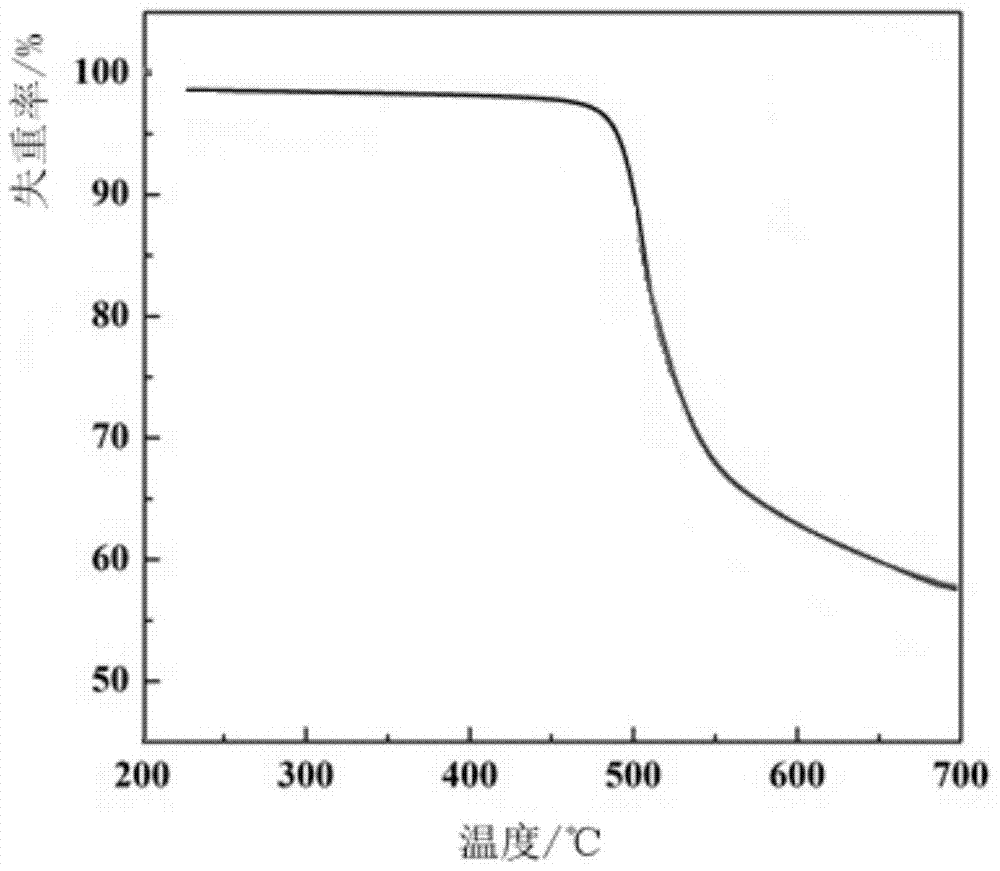

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com