Outer covering protection layer structure of car decorating part

A technology for automobile decoration and protective layer, which is applied in the direction of coating, superimposed layer plating, metal material coating process, etc. The effect of bright appearance and ultra-high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

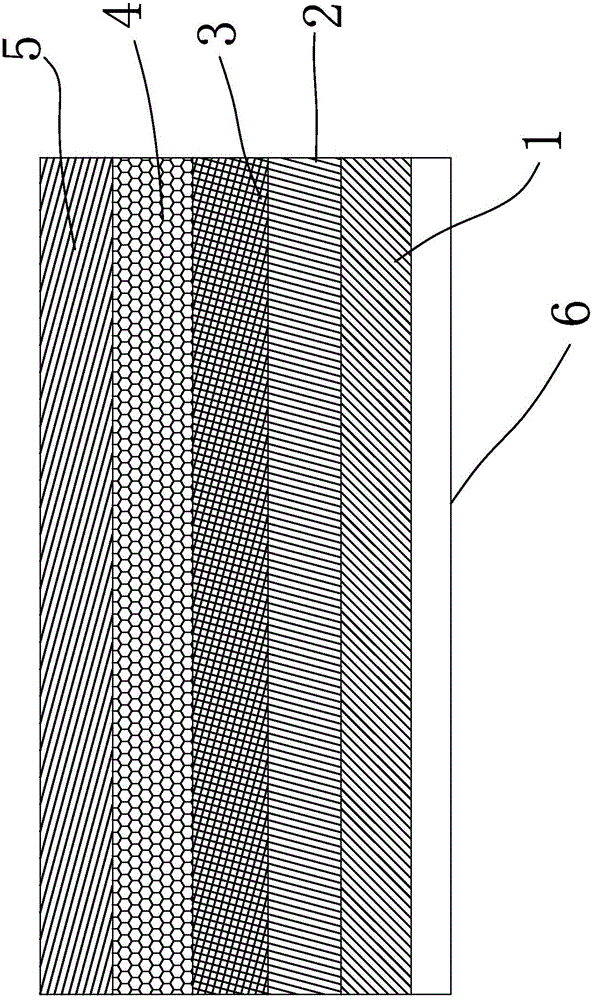

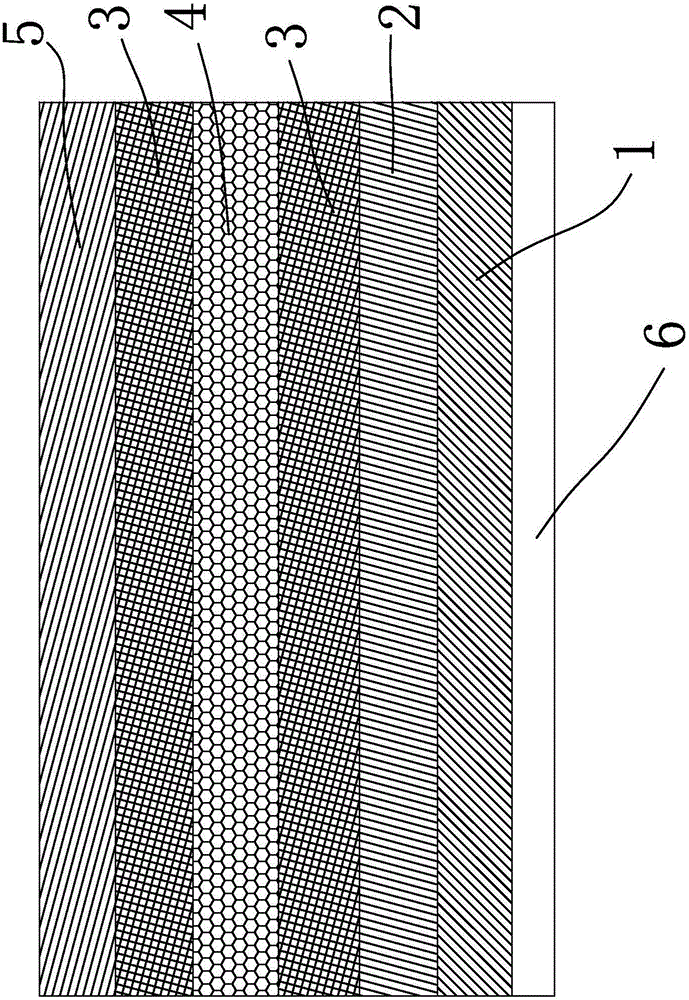

[0017] In the figure, a semi-gloss nickel layer 1; a full-gloss nickel layer 2; a micro-crack nickel layer 3; a microporous nickel layer 4; a decoration layer 5;

[0018] Such as figure 1 As shown, here the outer cover protective layer structure of the automobile decoration part is formed on the decoration body 6. There are mainly two ways. The first method includes the first layer, the second layer, the third layer and the fourth layer from the inside to the outside. And the fifth layer, the first layer is a semi-gloss nickel layer 1, the second layer is a full-gloss nickel layer 2, the third layer is a micro-cracked nickel layer 3, the fourth layer is a microporous nickel layer 4, and the fifth layer is a decorative Lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com