Guide-type heat radiator

A heat sink and oriented technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problem of low failure rate, achieve low failure rate, long service life, and enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

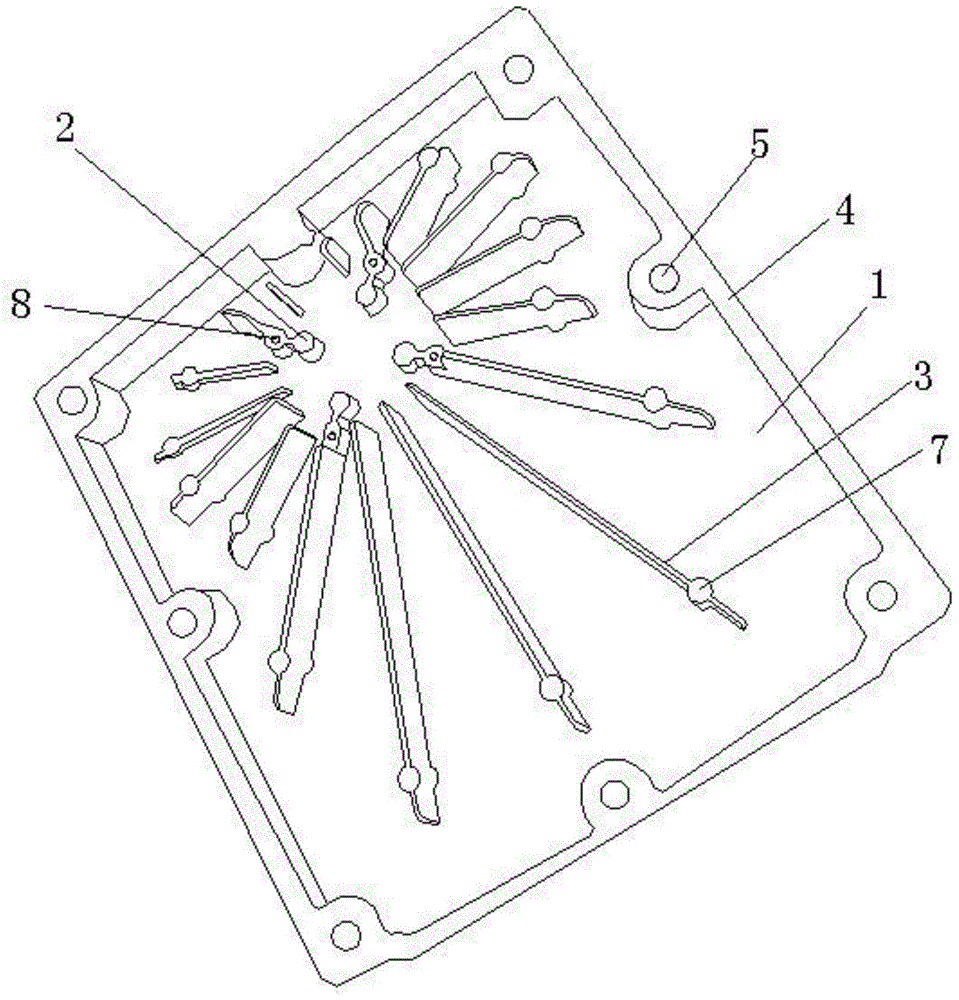

[0017] Such as Figure 1~2 As shown, a guide type radiator is characterized in that it includes: an inner concave shell 1, a number of fixing elements 2 for fixing the liquid pump are arranged in the groove of the inner concave shell 1, and several of the fixing elements A number of guide plates 3 are arranged radially around 2, and a distance is set between the ends of the guide plates 3 and the inner wall of the concave housing 1; flanges 4 are provided on the edge of the concave housing 1 , the flange 4 is provided with a plurality of mounting holes 5 for airtightly connecting the concave housing 1 .

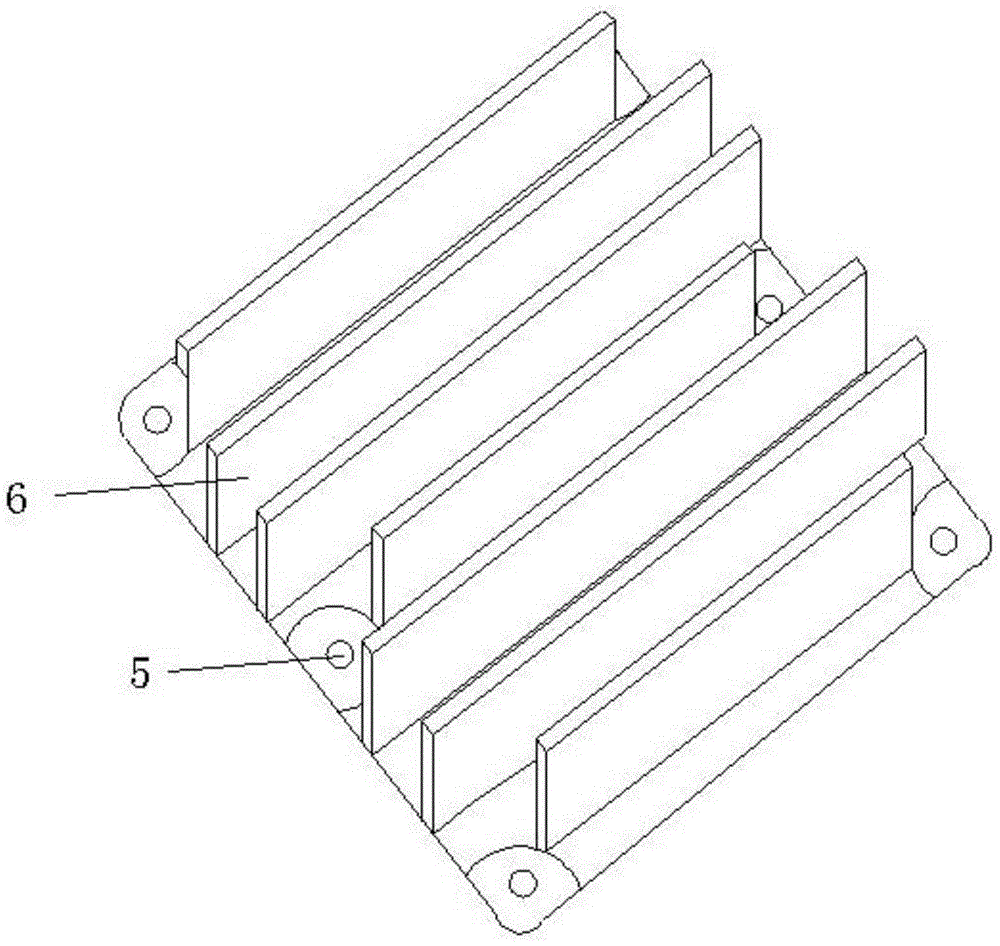

[0018] The back of the concave housing 1 is provided with several raised plates 6 for increasing the heat dissipation area.

[0019] The guide plate 3 is also provided with a contact post 7 for abutting against a device that is airtightly connected with the concave ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap