Wheel-driven fertilizer distributor

A wheel-driven fertilizer spreader technology, which is applied to fertilizer spreaders with centrifugal wheels, fertilization devices, fertilizer distributors, etc., can solve the problems of fuel consumption, high maintenance costs, and difficulty in controlling the movement of fertilizer spreaders alone, and achieve improved Ease of use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be described in detail with reference to the drawings.

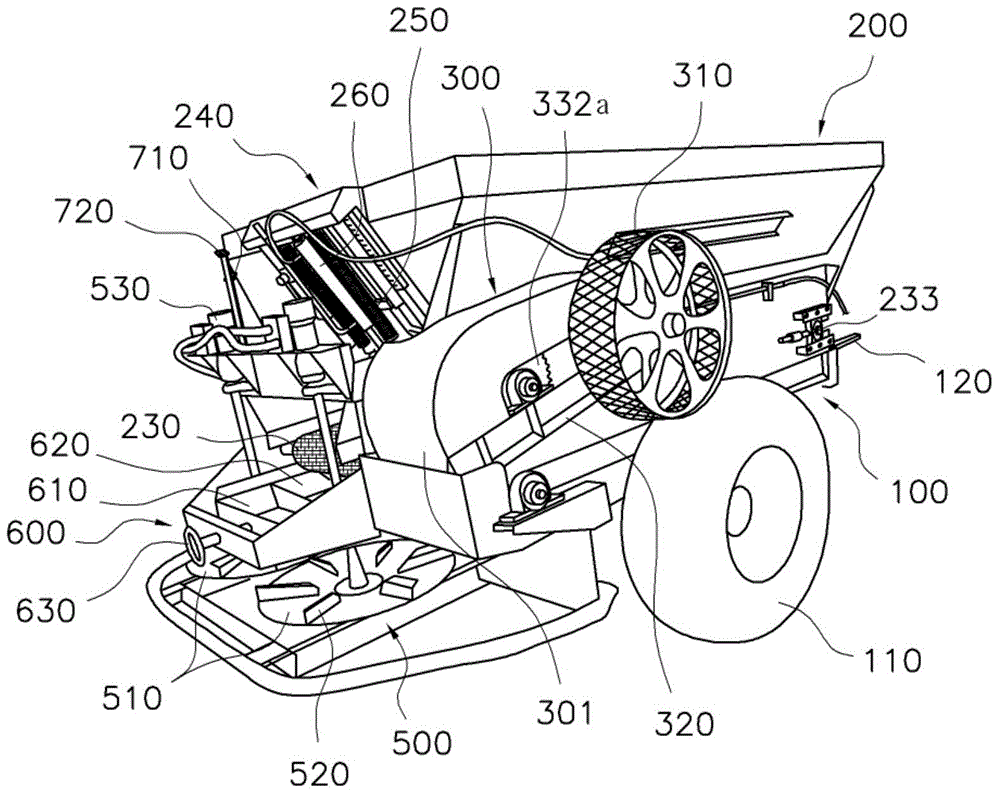

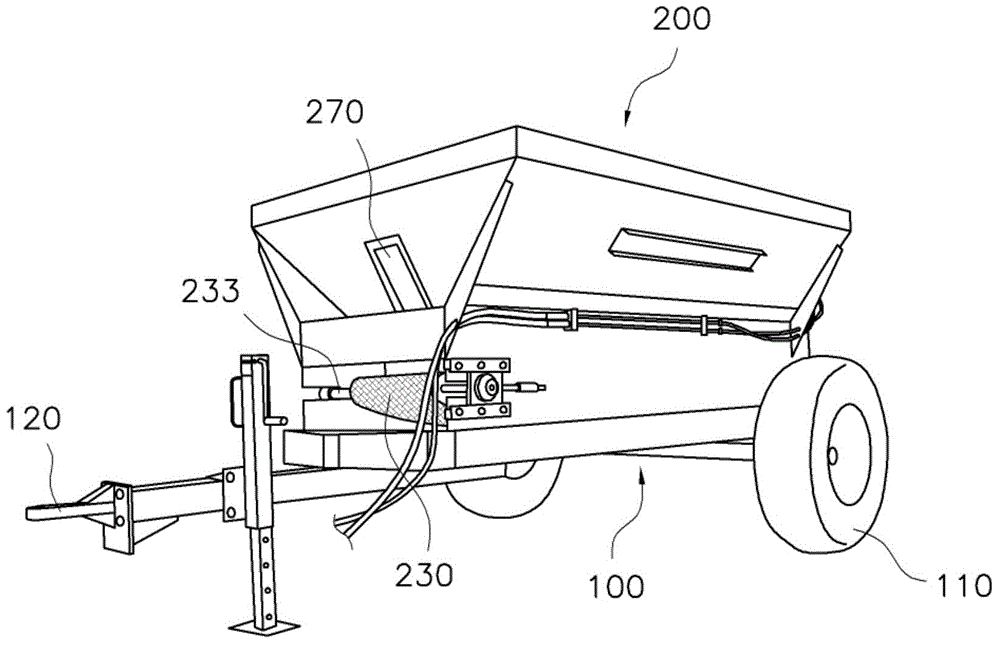

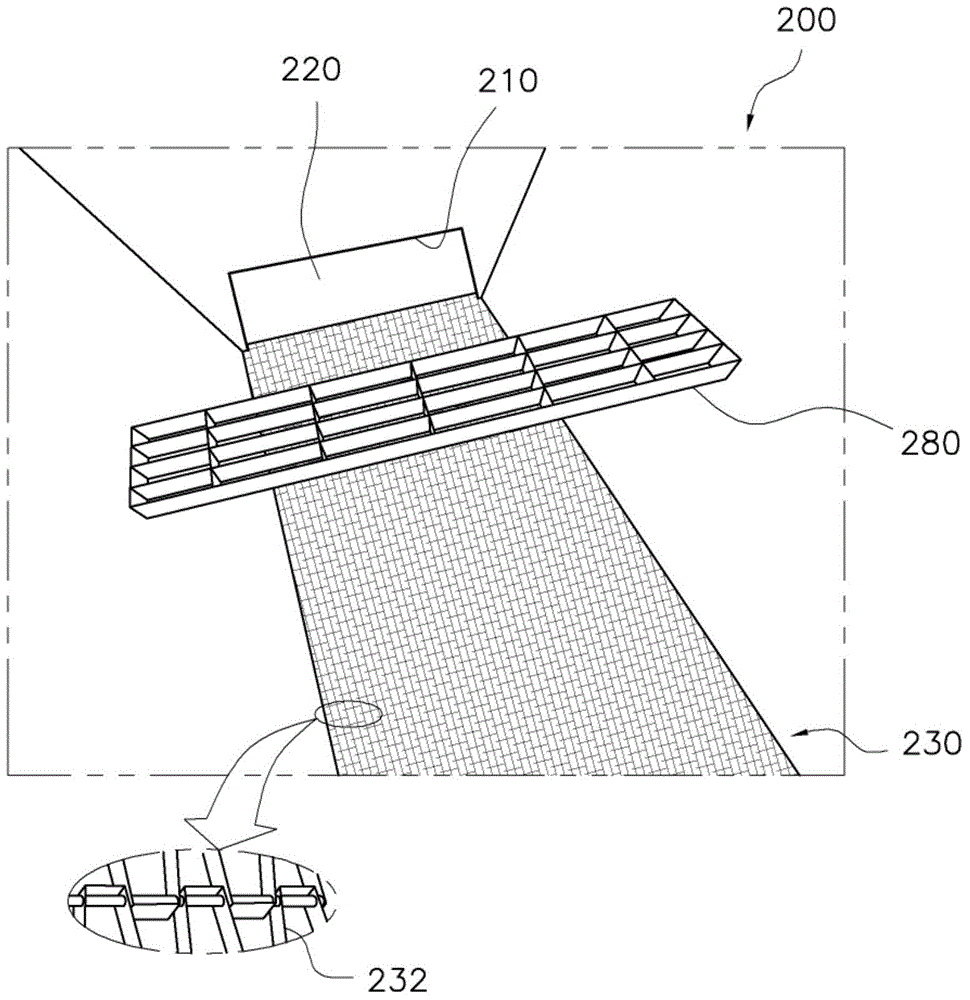

[0035] figure 1 It is a rear perspective view of the wheel-driven fertilizer spreader of the present invention, figure 2 is a front perspective view of the wheel-driven fertilizer spreader of the present invention, image 3 It is a schematic diagram showing the inside of the hopper in the wheel drive type fertilizer spreader of the present invention.

[0036] Figure 4 is a top view of the wheel-driven fertilizer spreader of the present invention, Figure 5 It is a schematic diagram of the operation of the main part of the wheel-driven fertilizer spreader of the present invention, (a) is a state diagram in which the transmission wheel is in contact with the wheel, and (b) is a state diagram in which the transmission wheel is separated from the wheel.

[0037] Figure 6 is true Figure 4 A magnified view of part A of the Figure 7 It is a schematic diagram which shows...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap