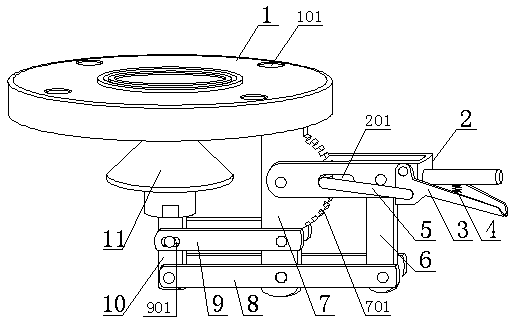

Rocker arm driven tapered piston type valve

A piston-type, arm-driven technology, applied in the direction of valve lifts, valve details, valve devices, etc., can solve the problems of fragile opening and closing mechanisms, time-consuming and labor-intensive manipulation, and easy failure of seals, so as to prolong the service life and overcome the easy failure of seals , The effect of low processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

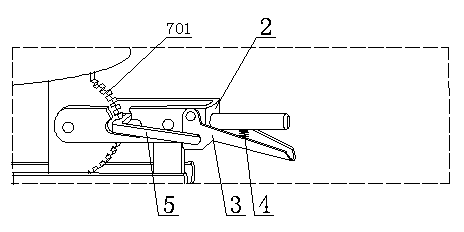

[0025] As shown in the figure, the rocker arm drives a tapered piston valve, including a valve body flange 1 and an opening and closing mechanism. The valve body flange 1 is provided with a bolt hole 101 for connecting and fixing the pipeline flange. , the valve body flange 1 is connected to the pipeline flange through bolts, and the middle is sealed with a gasket. The opening and closing mechanism consists of a bracket 7 fixed to the valve body flange 1, a handle 2 and a rocker 8 hinged on the upper and lower parts of the bracket 7, and a jig hinged between the middle of the handle 2 and the end of the rocker 8. The rod 6, the opening and closing piston 10 hinged at the other end of the rocking arm 8, the connecting rod 9 hinged between the opening and closing piston 10 and the bracket 7, and a handle locking mechanism. In this embodiment, the top of the bracket 7 is integrally cast with the valve body flange 1 , and the bracket 7 is perpendicular to the valve body flange 1 ....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap