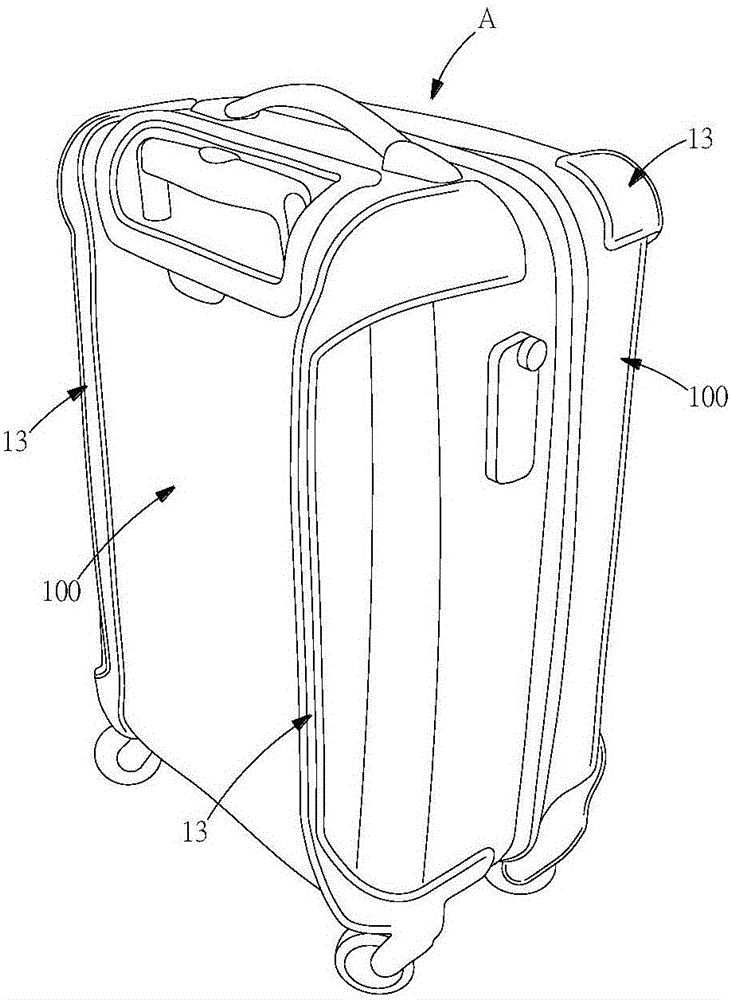

Luggage box body structure and its manufacturing method

A technology of box structure and luggage, which is applied in the field of shell structure, and can solve the problems of increasing the overall weight of luggage A and insufficient structural strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

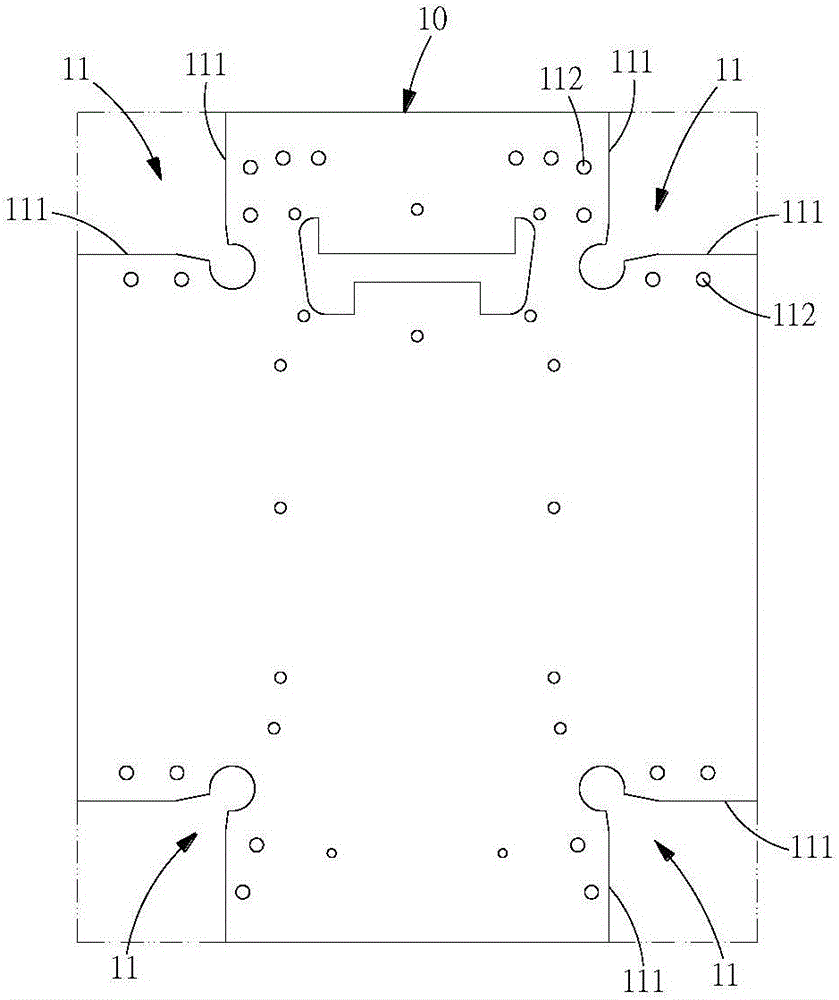

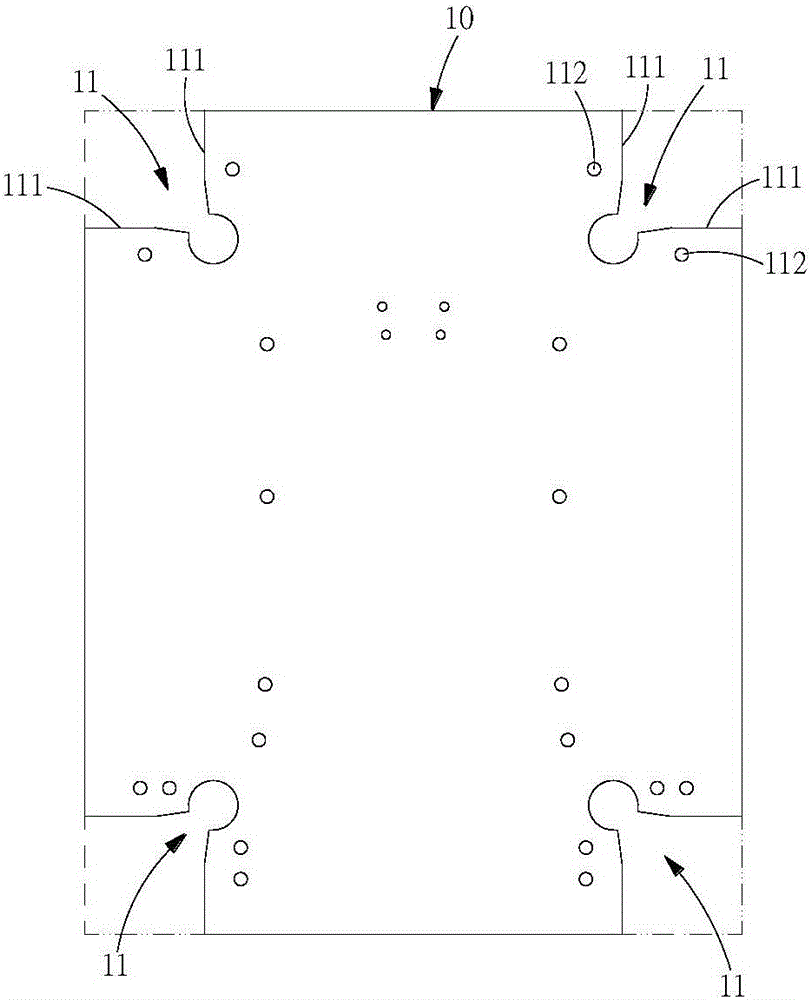

[0041] like Figure 4 to Figure 9D Shown, illustrate the embodiment of the trunk body structure of the present invention and its manufacturing method.

[0042] A suitcase body structure provided by the present invention consists of a flat shell plate 20 which is folded and shaped to form a three-dimensional concave structure body 30 . The box body 30 can be selected from thermoplastic composite materials such as PVC (Polyvinylchloride), PP (Polypropylene, Polypropylene) or PET (Polyethyleneterephthalate, Polyethyleneterephthalate), which are woven into single-layer or multi-layer The shell plate 20 of the structure is folded and shaped. Wherein, the manufacturing method steps of the casing 30 include:

[0043] A. Provide a rectangular flexible sheet made of thermoplastic composite material through weaving;

[0044] B. If Figure 8A As shown, four closed gaps 23 are provided adjacent to the plate and at positions equal to the vertical distance from the side of the plate;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com