Cold-formed thin-walled steel building interstory reinforcement components

A technology of cold-formed thin-walled steel and reinforced components, which is applied in the direction of construction and building construction, can solve the problems of difficult installation of exterior wall panels and limited popularization and application, and achieve increased house weight, improved capacity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

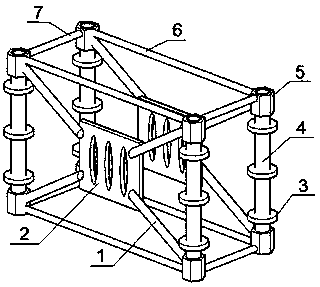

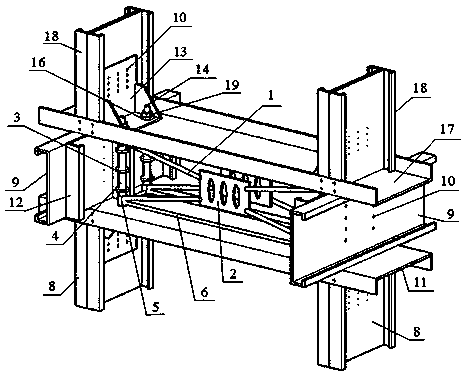

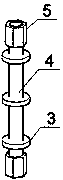

[0024] Such as figure 1 , a cold-formed thin-walled steel building interstory reinforcement component, characterized in that the reinforcement component is a truss structure: including four upright steel sleeves 4 arranged in a rectangular projection, fixed at both ends of the steel sleeves 4 and connected to The steel casing 4 is coaxial with the hollow support 5, and the adjacent hollow support 5 is welded with a horizontal horizontal steel bar 6 or a horizontal longitudinal steel bar 7. On the hollow support 5 at each corner, oblique steel bars 1 of equal length are welded along the diagonal direction, and the far-end of each oblique steel bar 1 is welded on a perforated steel plate 2 .

[0025] On the steel casing 4, reinforcing hoops 3 are welded between phases.

[0026] There are 3 vertical elliptical holes in the perforated steel plate 2, the major axis of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com