A Method for Improving the Performance of Thin Plate Friction Stir Welding Joints

A friction stir and welding joint technology, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of low bearing capacity of joints, difficult tooling, etc., and achieve improved inclusiveness, increased bearing area, and increased The effect of overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

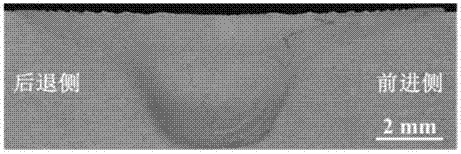

[0034] Specific implementation mode one: combine Figure 1 to Figure 4 and Figure 6 Describe this embodiment, a method for improving the performance of a thin plate friction stir welded joint in this embodiment, it includes the following steps:

[0035] Step 1. Preparation of butt welding plate:

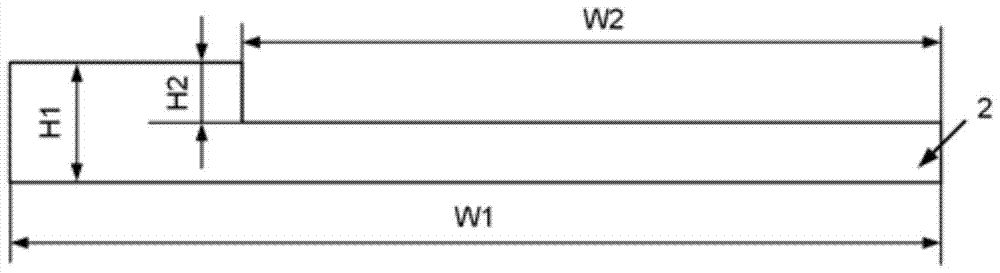

[0036]The butt welding plate 2 is processed by machining, and the length L1 is 200-400mm, the width W1 is 80-120mm, and the thickness H1 is 2-6mm; the butt welding plate 2 is milled, and the position of the milling is In order to carry out milling on the upper end surface of the butt welding plate 2 along its width direction based on one of the sides in the length direction, after milling off part of the plane, a boss with the same length as the butt welding plate 2 is left, and the milling width W2 is 60-100mm, milling depth H2 is 1-3mm;

[0037] Step 2, preparation of auxiliary board:

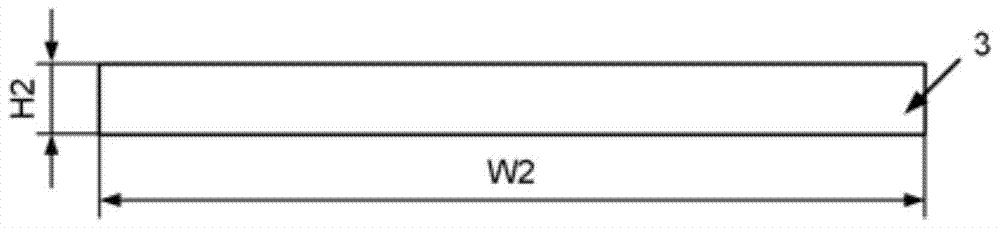

[0038] The auxiliary plate 3 is processed by machining, the length of the auxiliary plate 3...

specific Embodiment approach 2

[0045] Specific implementation mode two: combination Figure 1 to Figure 4 and Figure 6 To illustrate this embodiment, in step 1 of this embodiment, the length of the butt welding plate 2 is 300 mm, the width is 100 mm, the thickness is 4 mm, the milling width is 80 mm, and the milling depth is 2 mm. In this way, the thickness of the butt joint surface is 4mm, which can greatly reduce the difficulty of the plate butt joint tooling; the bearing capacity of the joint = joint strength × joint area, and the strength of the softening zone is about 60%-70% of the base metal, so the joint area should be the base metal Only 1.7-1.4 times of the base metal can guarantee the same bearing capacity as the base metal. Here, the thickness of the joint area is twice that of the base metal, and the load-bearing capacity of the joint area is more than 1.2 times that of the base metal. Even if there is weld thinning and small size The lack of welding will not significantly affect the load-bea...

specific Embodiment approach 3

[0046] Specific implementation mode three: combination Figure 1 to Figure 4 and Figure 6 To describe this embodiment, in step 2 of this embodiment, the width of the auxiliary plate 3 is 30 mm, and the thickness is 2 mm. Such setting ensures that the auxiliary plate 3 can provide good support for the butt welding plate 2 . Other connection methods are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com