A Pouring Robot with Component Analysis

A component analysis and manipulator technology, applied in the configuration of indicating equipment/measuring equipment, equipment for feeding molten metal into molds, casting molten material containers, etc., can solve problems such as increased production costs and lower product qualification rates, and achieve Improve the yield rate, reduce labor intensity, and improve the effect of functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

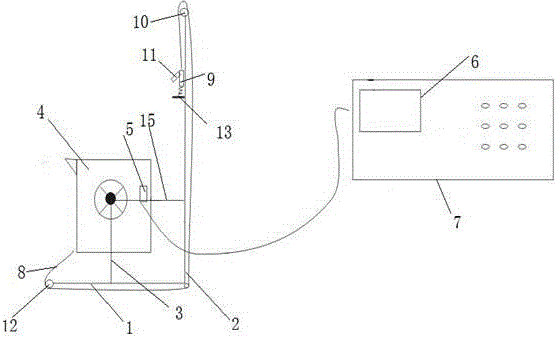

[0019] Such as figure 1 and figure 2 A pouring manipulator with component analysis is shown, including: base 1, bracket 2, fixed shaft 3, ladle 4, induction cup 5, component analysis module 6, manipulator console 7, steel wire rope 8, slider 9, Hook 10, sight 11, pulley 12 and spring 13, said component analysis module 6 is made up of analysis module, sampling module and display module, said manipulator console 7 includes manipulator, control system and control panel.

[0020] The relationship between the above components is as follows:

[0021] The support 2 and the fixed shaft 3 are vertically arranged on the base 1, the support 2 is also provided with a chute 14, the ladle 4 is fixed on the fixed shaft 3, and one end thereof is provided with a rotating shaft beam 15, so that The shaft crossbeam 15 and the support 2 are vertically arranged, the induction cup 5 is arranged on the shaft crossbeam 15 of the ladle 4, the analysis module and the sampling module are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com