Heating device of medical pipe plastic extruding machine

A technology for heating devices and extruders, which is applied in the field of heating devices and heating devices for medical pipe extruders. It can solve the problems of increasing the production and operation costs of enterprises, reducing the reliability of extruders, and the heating device is difficult to heat evenly. Achieve the effects of fast and accurate frequency conversion adjustment, prevent heat loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

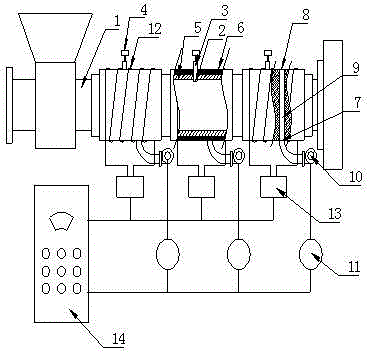

[0014] Such as figure 1 As shown, a heating device for a medical pipe extruder includes a barrel 1, and several temperature measuring tanks 2 are uniformly arranged on the barrel 1, and a temperature control probe 3 is arranged on the temperature measuring tank 2 , the temperature control probe 3 is connected with a temperature sensor 4, the outer wall of the barrel 1 is provided with a layer of thermal insulation cotton 5, the outer ring of the thermal insulation cotton 5 is provided with an insulating plate 6, and the insulating plate 6 is A plurality of air inlets 7 and air outlets 8 matched with the air inlets 7 are evenly arranged, and a cooling passage 9 is arranged between the air inlets 7 and the air outlets 8, and the air inlet 7 is connected with a fan 10, and the fan 10 A fan controller 11 is connected, and several electromagnetic induction coil groups 12 are evenly wound on the insulating plate 6, and the electromagnetic induction coil group 12 is connected with an...

Embodiment 2

[0017] Such as figure 1 As shown, a heating device for a medical pipe extruder includes a barrel 1, and several temperature measuring tanks 2 are uniformly arranged on the barrel 1, and a temperature control probe 3 is arranged on the temperature measuring tank 2 , the temperature control probe 3 is connected with a temperature sensor 4, the outer wall of the barrel 1 is provided with a layer of thermal insulation cotton 5, the outer ring of the thermal insulation cotton 5 is provided with an insulating plate 6, and the insulating plate 6 is A plurality of air inlets 7 and air outlets 8 matched with the air inlets 7 are evenly arranged, and a cooling passage 9 is arranged between the air inlets 7 and the air outlets 8, and the air inlet 7 is connected with a fan 10, and the fan 10 A fan controller 11 is connected, and several electromagnetic induction coil groups 12 are evenly wound on the insulating plate 6, and the electromagnetic induction coil group 12 is connected with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com