Method for manufacturing double-curved-surface lens

A production method and hyperboloid technology, which can be applied to other home appliances, optical components, home appliances, etc., can solve the problems of monotonous style and no new ideas, achieve beautiful appearance and improve the effect of thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

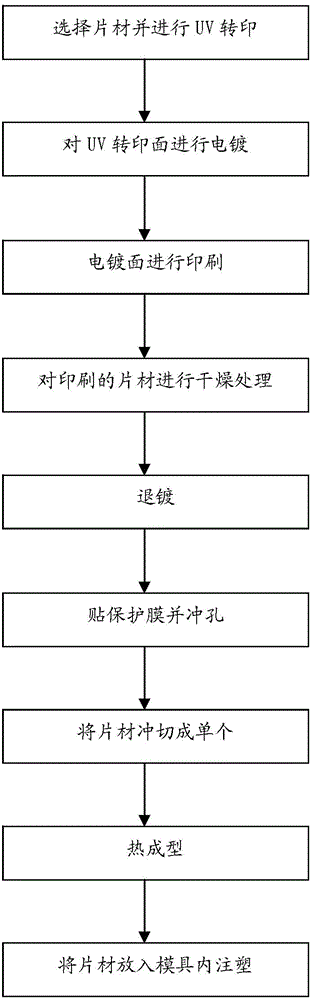

[0037] Please refer to FIG. 1 , this embodiment provides a method for manufacturing a hyperboloid lens, and the process flow is as follows:

[0038] Select the sheet and carry out UV transfer - electroplating on the UV transfer surface - printing on the electroplating surface - drying the printed sheet - stripping - attaching a protective film and punching - punching the sheet into individual pieces - thermoforming —Put the sheet into the mold for injection molding.

[0039] Specifically include the following steps:

[0040] S01. Select a sheet and perform UV transfer printing on the sheet; wherein, the material of the sheet is any one of PC and PET, and the thickness of the sheet is preferably 0.125-0.15 mm. Among them, light curing is carried out at a speed of 20-30m / min, and the energy is 800-1000mj / cm 2 Curing treatment of UV transfer sheet.

[0041] S02, carrying out one-side electroplating (UV transfer printing one side) to the sheet material of UV transfer printing; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com