An escalator glass clamp bracket

A technology for escalators and glass, which is applied in escalators, transportation and packaging, etc. It can solve the problems of glass asymmetry on both sides, cumbersome assembly process, and low positioning accuracy, so as to achieve high installation strength and save the need for screwing bolts and clamping The effect of simple steps and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

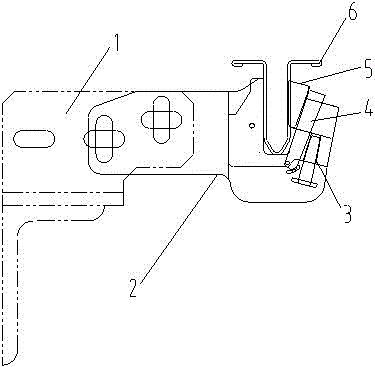

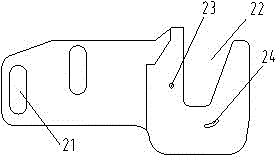

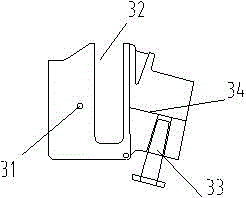

[0022] according to Figure 1 to Figure 6 Shown, a kind of escalator glass tightening part bracket comprises mounting frame 1 and tightening device, and described tightening device is made up of lower plate 2, upper plate 3, push plate 4, slide block 5 and glass bracket 6, and described lower One end of the plate 2 is provided with a rectangular hole 21 that can be adjusted up and down, the other end is provided with a gap 22, a lower plate connection hole 23 and a shaft pin sliding groove 24, and one side of the thin side of the upper plate 3 is provided with an upper plate connection hole 31 And the U-shaped groove 32, the other side of the high platform is provided with a tightening bolt 33 and a baffle 34, the upper plate 3 is fixedly connected with the lower plate 2 through the upper plate connection hole 31, and the push plate 4 is provided with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap