Bracket for forklift

A technology of brackets and forklifts, which is applied in the direction of lifting devices, etc., which can solve the problems of easy corrosion service life, unstable placement, low bearing capacity, etc., and achieve the effects of saving usage, avoiding left and right shaking, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

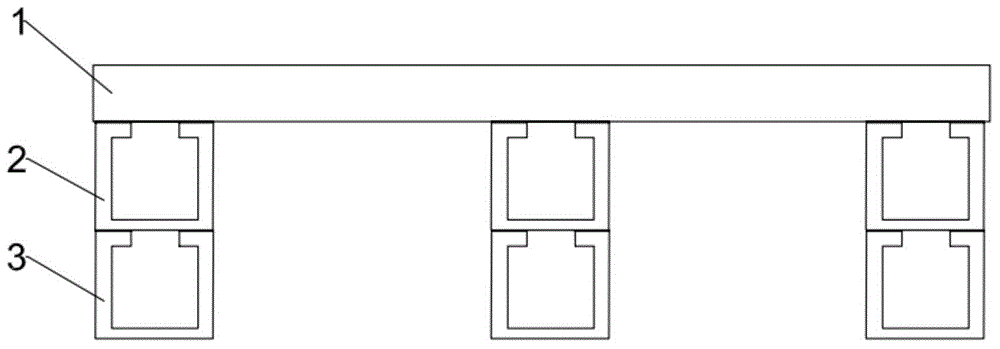

[0016] Such as figure 1 , figure 2 As shown, the technical solution provides a bracket for forklifts, including a bracket part and a support part for supporting the bracket part, the bracket part includes several evenly distributed cuboid bracket panels 1, and the inside of the bracket panel 1 It is a hollow structure to reduce the load of the bracket; the support part includes several support bodies 2, the support body 2 is a cuboid structure, and the inside of the support body 2 is set as a hollow structure to reduce the load of the bracket. 2 is connected to the bracket part along the vertical direction of the bracket panel 1. The middle part of the contact surface between the support body 2 and the bracket panel 1 is provided with a notch along its length direction, so that on the one hand, the supporting area between the support body 2 and the bracket panel 1 is guaranteed, and the side wall of the bracket panel 1 against the support body 2 is avoided. Stress concentra...

Embodiment 2

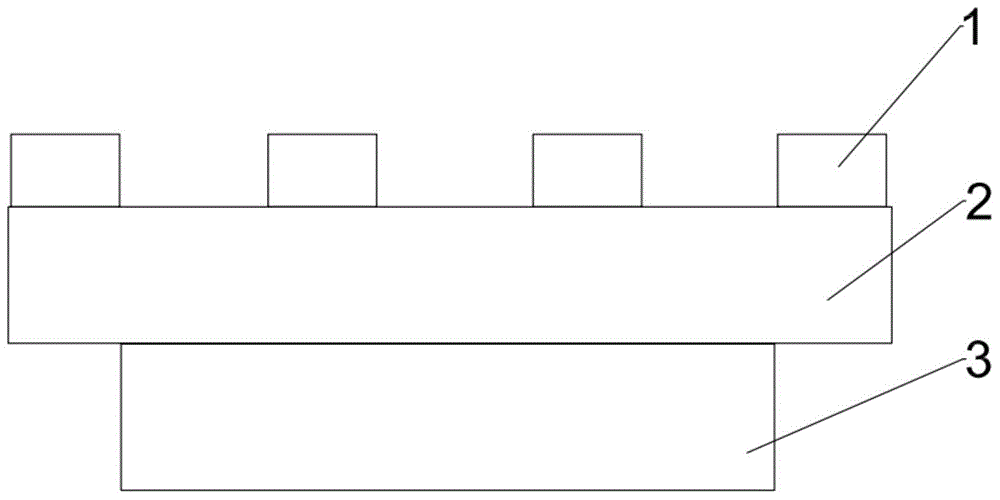

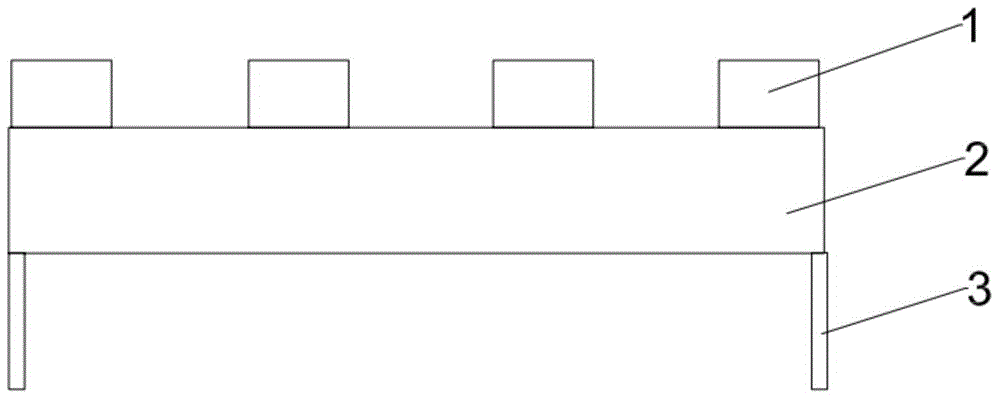

[0019] Such as image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in. The positioning parts 3 in this embodiment are respectively fixedly welded on the two end surfaces of the support body 2. When in use, the positioning parts 3 on the two end surfaces of the support part are snapped onto the outer side walls of the two horizontal bars corresponding to the storage rack, so that the support body The rack is fixed on the storage rack, this solution can greatly save the use of materials and reduce the load of the bracket.

[0020] In the process of actual operation, the goods are placed on the upper surface of the bracket part, and the bracket is lifted by inserting a forklift between the two support bodies 2 and sent to the storage rack. Since the positioning piece 3 is fixedly installed on the lower part of the support body 2, during the placement process, the positioning piece 3 can be quickly positioned to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com