Compound fabric ironing device

A technology of composite fabrics and fabrics, applied in fabric surface trimming, textiles and papermaking, etc., can solve the problems of easy damage, unevenness, etc., and achieve the effect of preventing scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

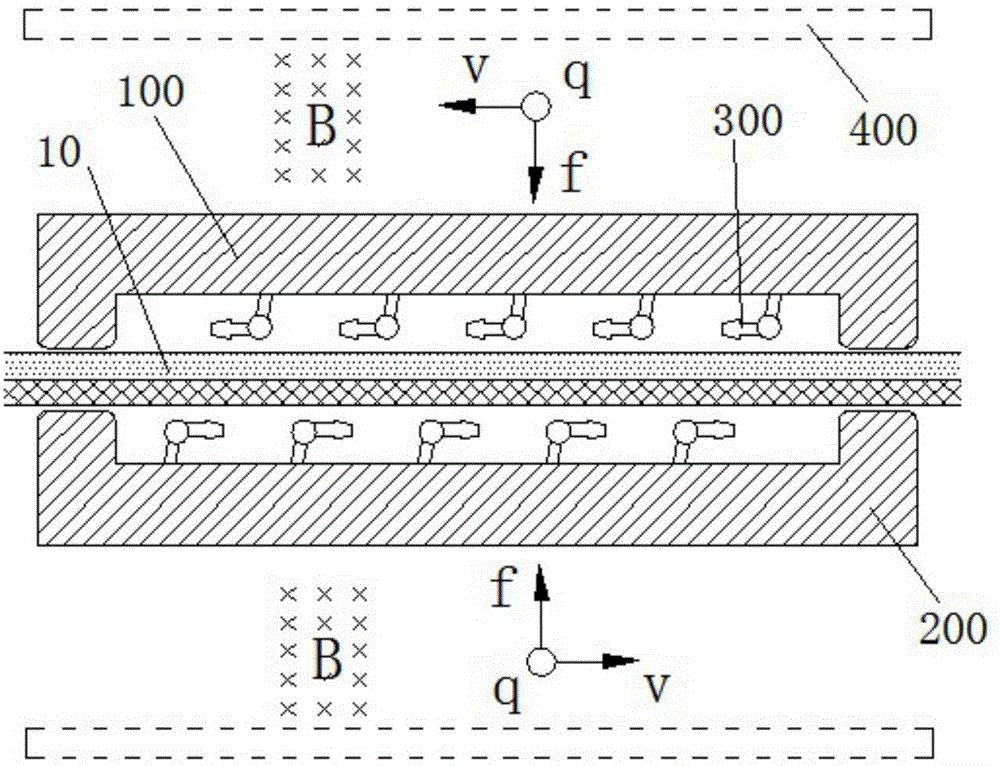

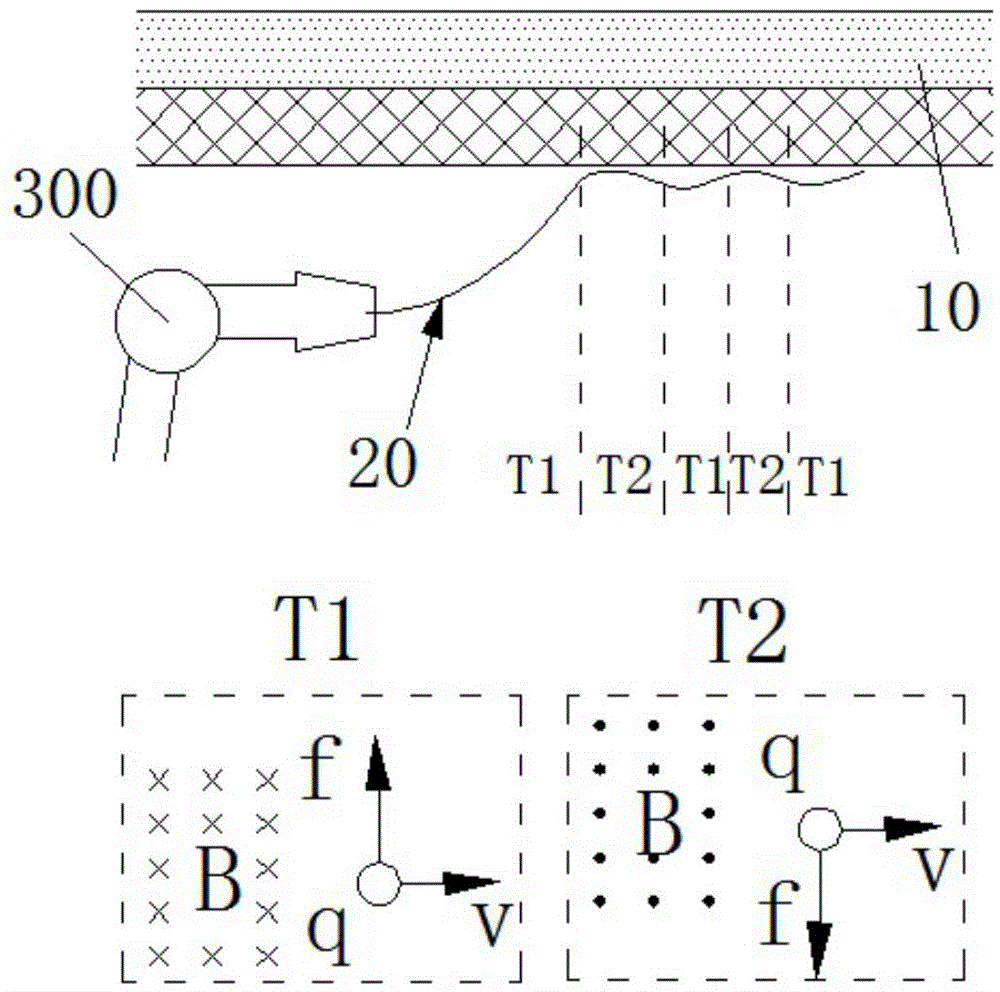

[0014] refer to figure 1 , in this embodiment, the composite fabric ironing device includes an upper cover 100 and a lower cover 200 arranged in parallel, the fabric 10 passes between the upper cover 100 and the lower cover 200, and the upper cover 100 The lower surface of the lower cover plate 200 and the upper surface of the lower cover plate 200 are provided with accommodating chambers, and steam vents 300 are evenly distributed in the accommodating chambers. The steam jets 300 of the same cover plate have the same steam jetting direction, the steam jets 300 are provided with an electrostatic generator inside, and the two sides of the fabric 10 are provided with a controllable alternating magnetic field perpendicular to the steam jets 300 jetting direction.

[0015] The steam nozzles 300 on the upper cover plate 100 and the lower cover plate 200 lead to differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com