Anti-scald hollow self-heated lunch box

A self-heating, lunch box technology, applied in clothing, heating devices, accessories, etc., can solve the problems of broken glass platform, large heat loss, inconvenience, etc., to achieve more uniform heating effect, less heat conduction, and heat fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

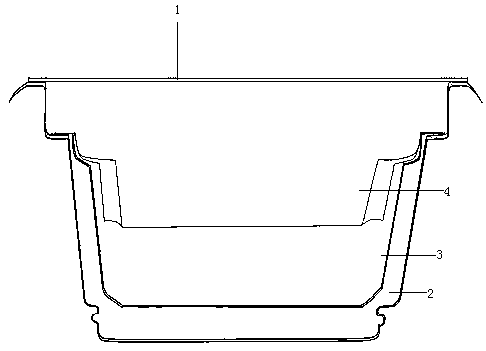

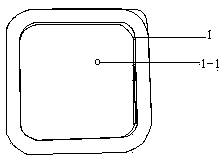

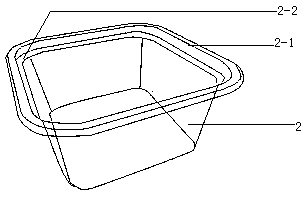

[0019] figure 1 , 2 , 3, 4, and 5, an anti-scalding hollow self-heating lunch box is composed of a box cover 1, an outer box 2, an inner box 3 and an inner box 4, and the box cover 1, the outer box 2, and the inner box 3 And the inner box 4 is a square structure, the outer box 2, the inner tank 3 and the upper part of the inner box 4 each have a ladder-shaped force-bearing support surface extending outwards, and the inner tank 3 top surrounding the ladder-shaped force-bearing support surface 3-1 The outermost front, rear, left, and right widths are 0.5 mm wider than the lower end 2-2 of the ladder-shaped force-bearing support surface 2-1 around the top of the outer box 2, and the outermost width of the ladder-shaped force-bearing support surface 4-1 around the top of the inner box 4 The front, rear, left, and right widths are 0.5 mm wider than the front, rear, left, and right widths of the lower end 3-2 of the ladder-shaped force-bearing support surface 3-1 around the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com