Method for handling high-low strides at adjacent parts of reverse building foundation pit and adjacent foundation pit

A technology of adjacent foundation pits and treatment methods, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of discontinuous structural force transmission, secondary economic waste, and construction period limitations of adjacent foundation pits, so as to shorten the construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

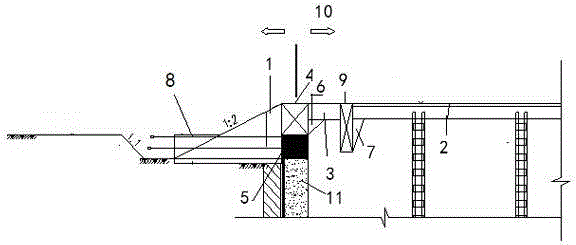

[0015] Such as figure 1 , as shown in 2, a method for dealing with the high and low spans adjacent to the adjacent foundation pit and the adjacent foundation pit, the specific steps are:

[0016] 1) Construction of enclosing cast-in-place piles 11, and fabrication of topping ring beams 5;

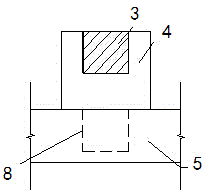

[0017] 2) Carry out the construction of the top plate 2 of the reverse foundation pit structure 10, the top plate 2 and the top ring beam 5 are connected by the connecting beam 3, and the top plate 2 of the reverse foundation pit and the adjacent side of the adjacent foundation pit have a height difference. The "corbel" 1 composed of the high-pressure top ring beam 4 and the transition section with variable cross-section;

[0018] 3) After the joints of the "corbel" 1 and the supporting beam 8 of the adjacent foundation pit are completed, the foundation pit 10 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com