A kind of preparation method of straight channel magnetic material

A magnetic material and straight channel technology, applied in the direction of inorganic material magnetism, silicon dioxide, silicon oxide, etc., can solve the problems of cumbersome self-assembly process, limited material load capacity, sample variability and rupture, etc., to achieve easy acquisition, movement Small resistance, the effect of reducing the penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

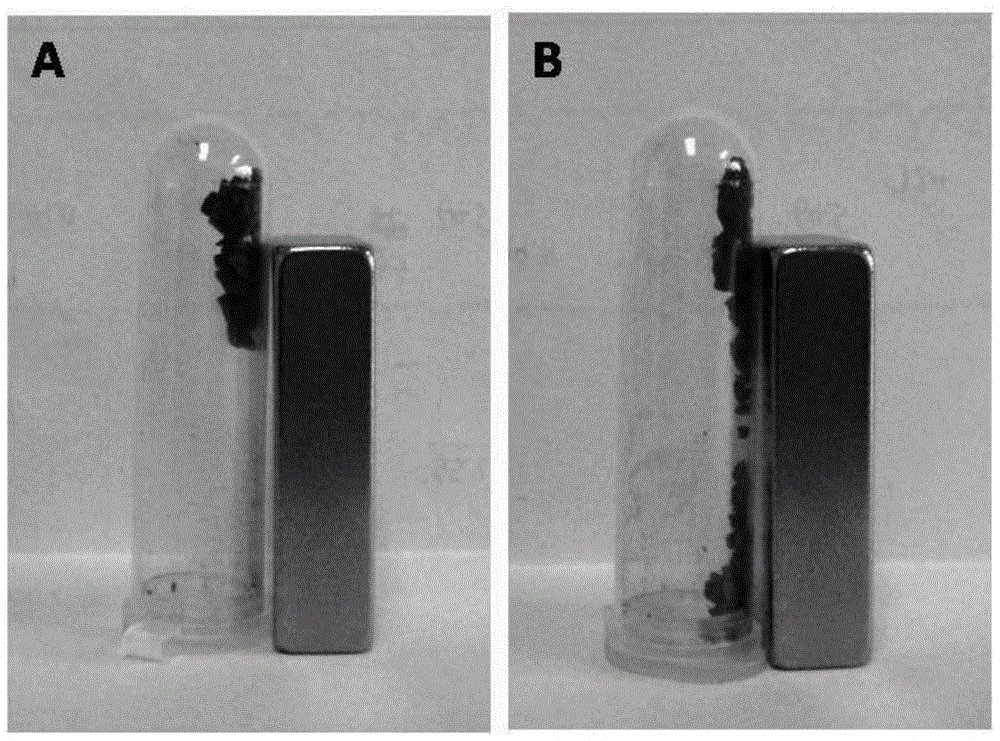

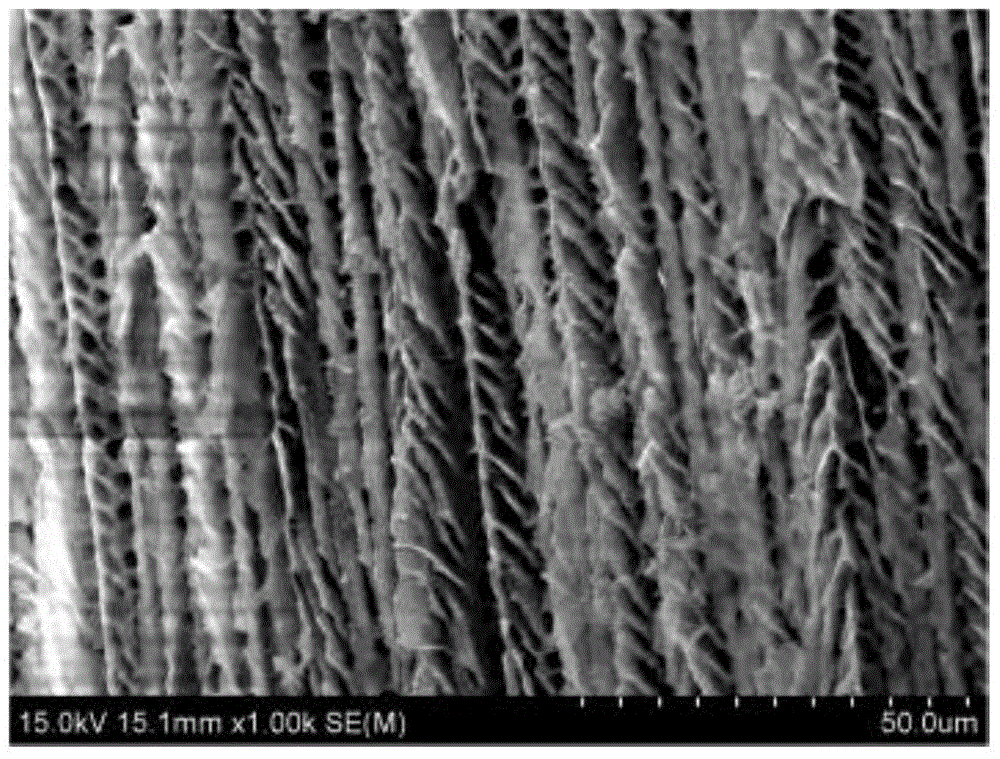

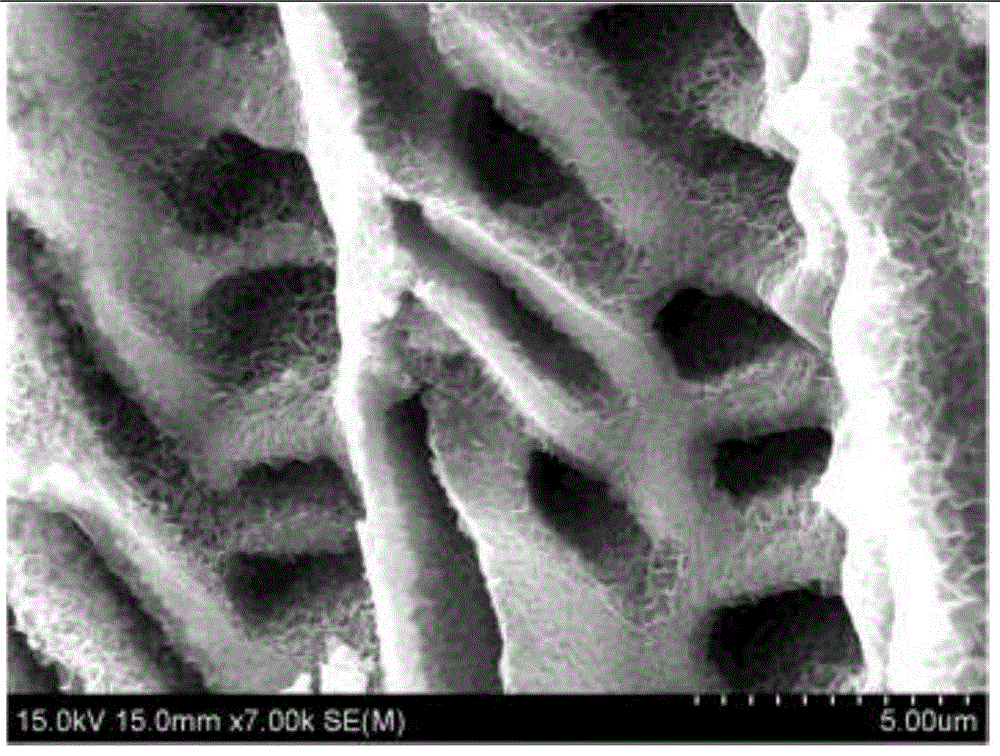

[0033] Measure 6ml of 5wt% PVA solution, add 3g of SDS to obtain a PVA solution containing 0.5g / ml SDS, mix with 6ml of 40wt% silica sol, place on a magnetic stirrer, and stir at room temperature to make the silica sol evenly dispersed in the solution. The resulting dispersion was placed in a beaker and slowly immersed in liquid nitrogen to freeze the dispersion into a solid state. Put the frozen sample into a vacuum freeze dryer whose temperature has reached -60°C, turn on the vacuum mode, and operate the vacuum freeze dryer for 48 hours in the vacuum freeze mode, and take out the sample. Put the sample in a crucible and put it into a resistance furnace for calcination, heat up to 800°C at 5°C / min, stop heating after holding for 1 hour, let it cool naturally in the furnace to room temperature, and obtain a straight-channel silica block. Immerse the silica block in 0.5 M FeCl 3 In the aqueous solution, and draw a vacuum, hold the pressure for 30 minutes, take out the sample, ...

Embodiment 2

[0040] Measure 6ml of 5wt% PVA solution, add 3g of SDS to obtain a PVA solution containing 0.5g / ml SDS, mix with 6ml of 40wt% silica sol, place on a magnetic stirrer, and stir at room temperature to make the silica sol evenly dispersed in the solution. The resulting dispersion was placed in a beaker and slowly immersed in liquid nitrogen to freeze the dispersion into a solid state. Put the frozen sample into a vacuum freeze dryer whose temperature has reached -60°C, turn on the vacuum mode, and operate the vacuum freeze dryer for 48 hours in the vacuum freeze mode, and take out the sample. The sample was placed in a crucible and calcined in a resistance furnace, and the temperature was raised to 900°C at a rate of 5°C / min. After holding for 1 hour, the heating was stopped, and it was naturally cooled to room temperature in the furnace to obtain a silica block with straight channels. Immerse the silica block in 0.5 M FeCl 3 In the aqueous solution, and draw a vacuum, hold the ...

Embodiment 3

[0042]Measure 6ml of 2.5wt% PVA solution, add 3g of SDS to obtain a PVA solution containing 0.5g / ml SDS, mix it with 6ml of 40wt% silica sol, place it on a magnetic stirrer, and stir at room temperature to disperse the silica sol evenly in the solution . The resulting dispersion was placed in a beaker and slowly immersed in liquid nitrogen to freeze the dispersion into a solid state. Put the frozen sample into a vacuum freeze dryer whose temperature has reached -60°C, turn on the vacuum mode, and operate the vacuum freeze dryer for 48 hours in the vacuum freeze mode, and take out the sample. The sample was placed in a crucible and calcined in a resistance furnace, and the temperature was raised to 900°C at a rate of 5°C / min. After holding for 1 hour, the heating was stopped, and it was naturally cooled to room temperature in the furnace to obtain a silica block with straight channels. Immerse the silica block in 0.5 M FeCl 3 In the aqueous solution, and draw a vacuum, hold t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com