Capacitively coupled electric field control device

A capacitive coupling, electric field technology, used in instruments, optics, lenses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

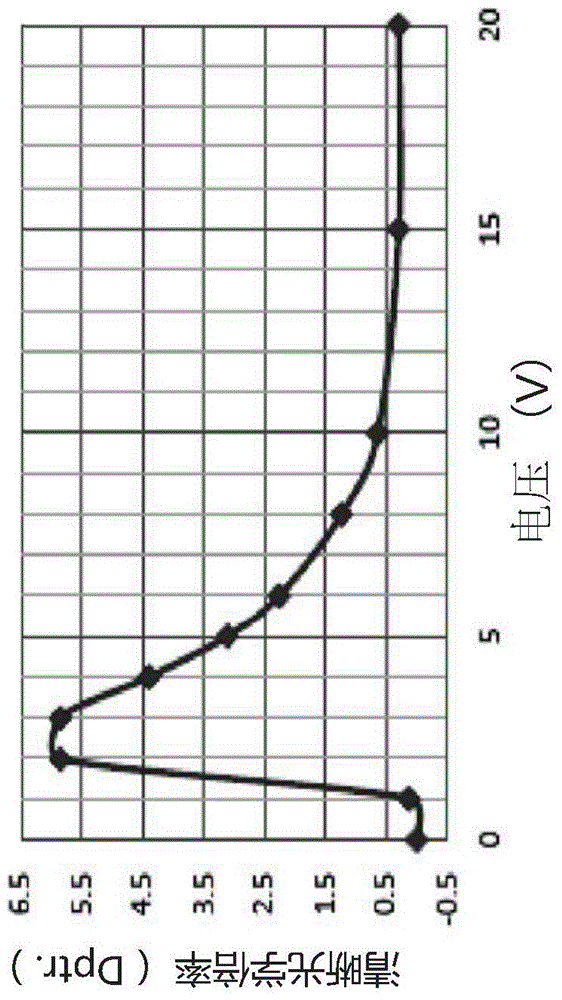

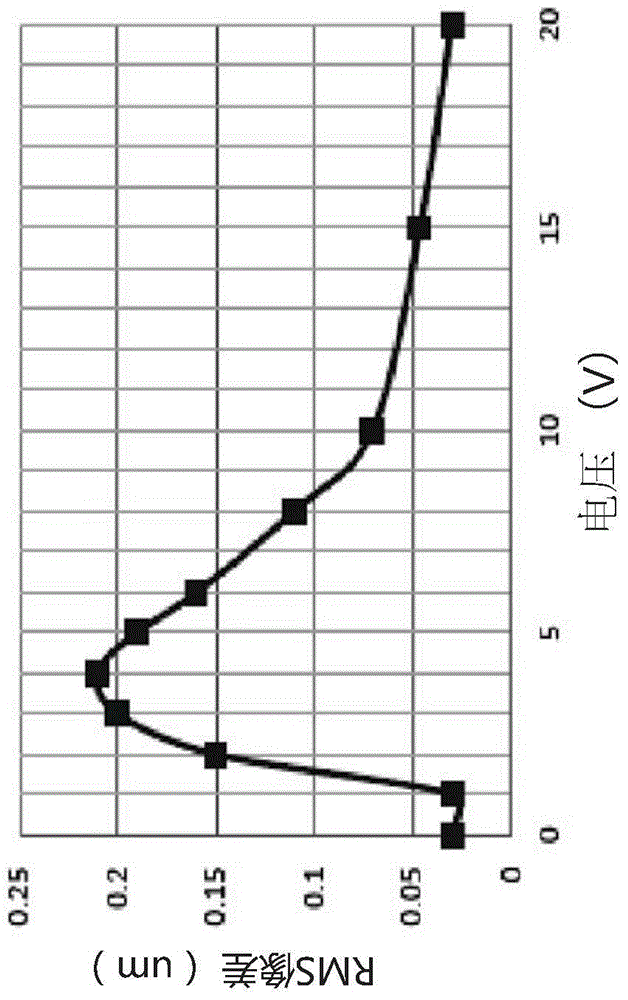

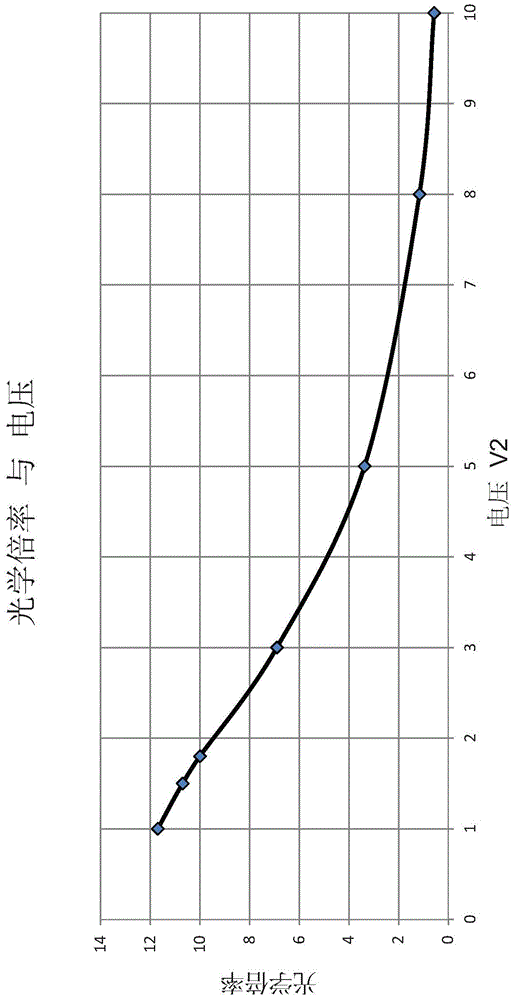

[0080] Structure and operation of capacitive coupling optical device

[0081] The technical problems mentioned above can be solved by a different method based on capacitive coupling. Picture 10 The working principle of realizing this coupling is shown schematically. Two electrodes 901 / 902 arranged close enough to realize the voltage coupling are used, and a capacitance C is formed between the electrodes 901 / 902 (for example only)

[0082] C=ε r ε 0 A / d,

[0083] Where A is the area of the overlapping area of the two plates, ε r Is the static relative permittivity of the spacer material (also called "intermediate material") between the two plates, ε 0 Is the dielectric constant of the vacuum and d is the separation distance between the plates.

[0084] The solution proposed in this application is the coupling or transfer of the voltage from the electrically connected electrode 901 to another floating electrode 902. Experiments confirmed as Picture 11 As shown, two electrodes are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap