Continuous hobbing method for straight bevel gear

A straight-toothed bevel gear and processing method technology, which is applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve the problem of not being able to meet the needs of flexible production and increasingly small batches of single pieces, Problems such as poor processing versatility and low processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

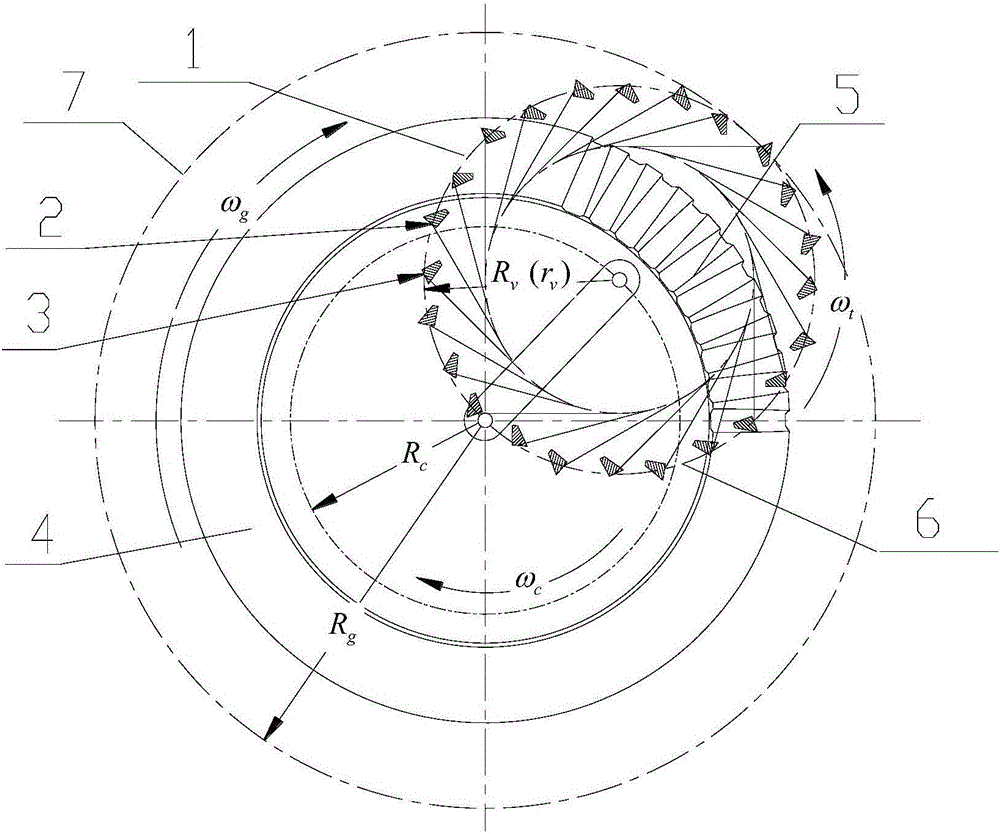

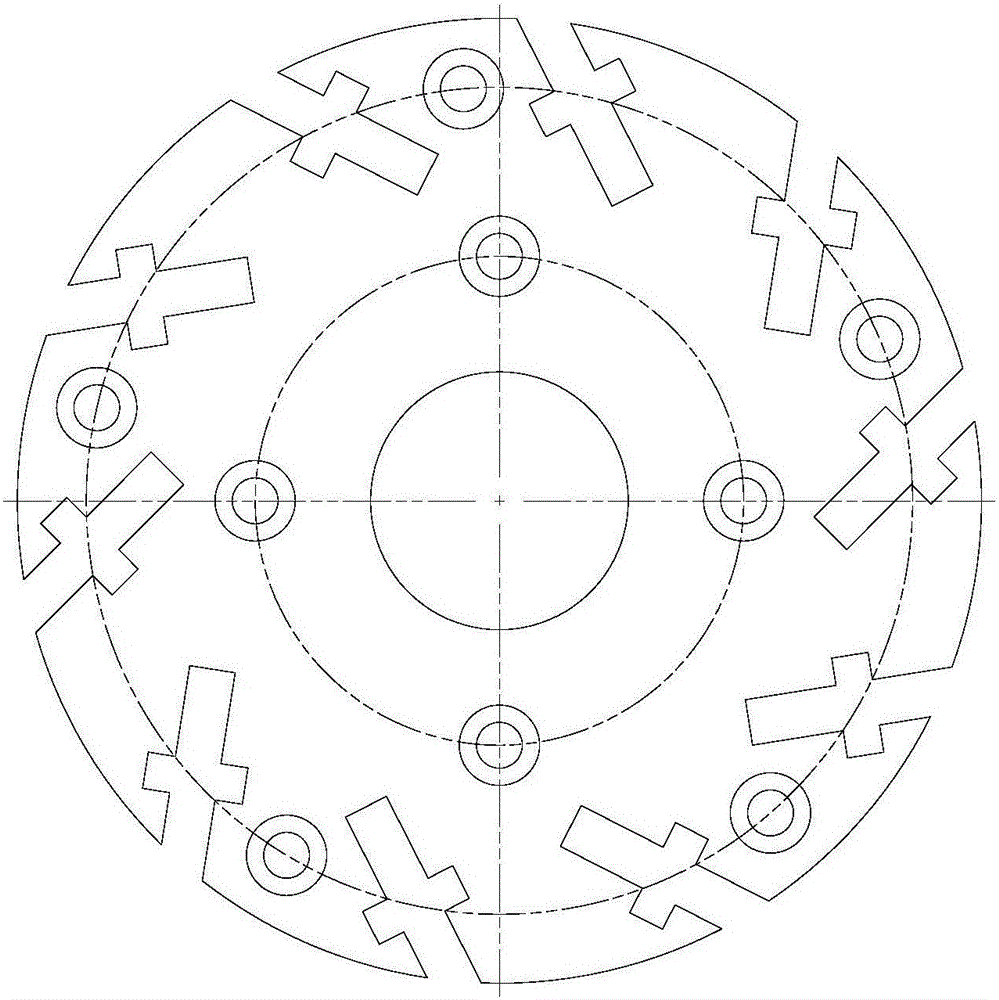

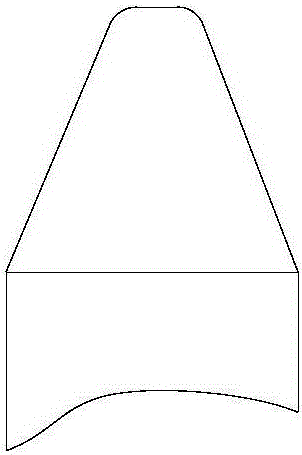

[0055] Such as figure 1 As shown, the basic principle of the present invention is based on a special hypocycloid approximating a straight line, and the cutter head is ω t The speed rotates, and the gear rotates at ω gThe speed of rotation, at this time the relative movement of the gear and the tool is equivalent to the tool rolling 1 (radius R v ) and gear rounding 7 (radius R g ) for pure rolling meshing motion. When the tool rounds 1 radius and the reference radius r v When consistent and equal to half the radius of the gear rolling circle 7, that is, R v = r v = R g / 2, the trajectory formed by the tip of the cutter tooth on the gear is an approximate straight line, which can be used for continuous hobbing of straight bevel gears.

[0056] In actual processing, since the cutter head, gear and number of teeth cannot strictly meet the above theoretical requirements, it is difficult to achieve an absolute straight line for the processed tooth profile. In fact, this abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com