Steel bar connecting end polishing and threading equipment and application method thereof

A technology for connecting ends and threading, which is used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve problems such as being unfavorable to project cost and schedule control, affecting the tensile performance of butt-jointed steel bars, and unfavorable project quality, etc. Achieve the effect of avoiding secondary handling, avoiding cutting workers, and connecting securely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

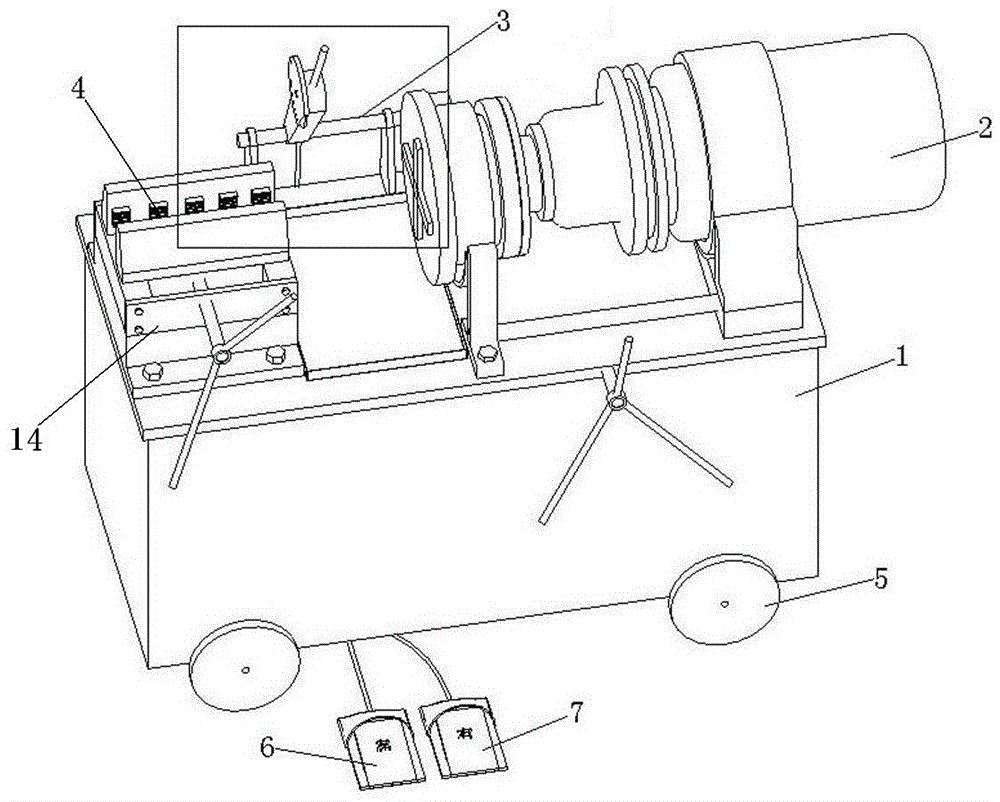

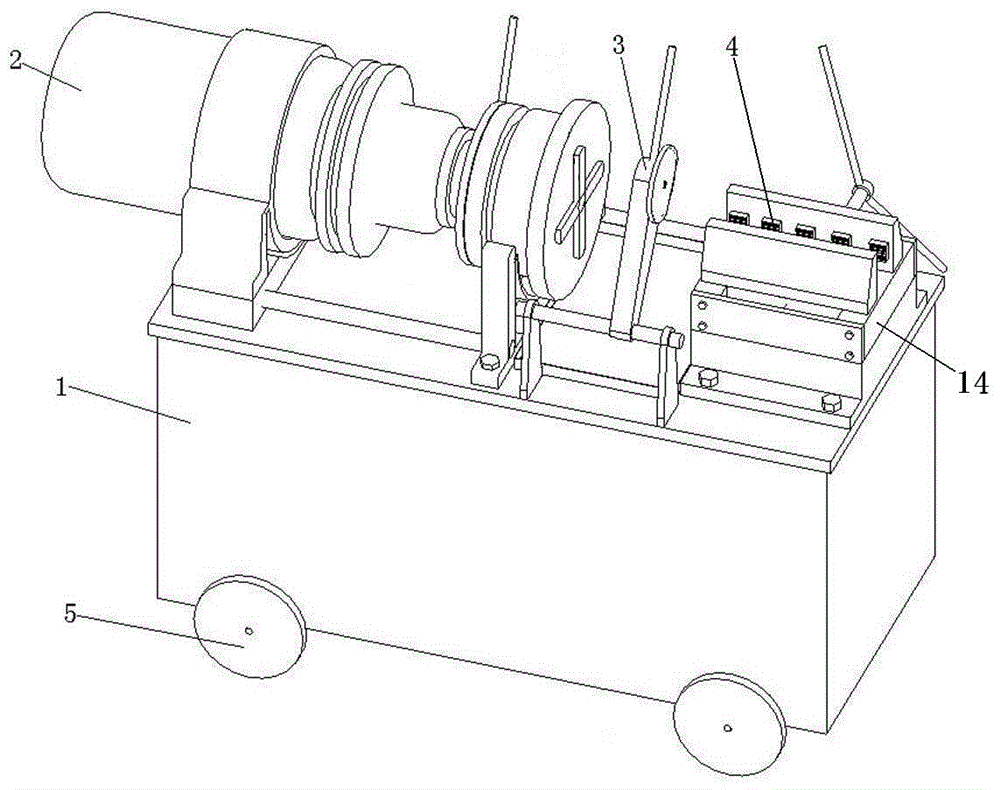

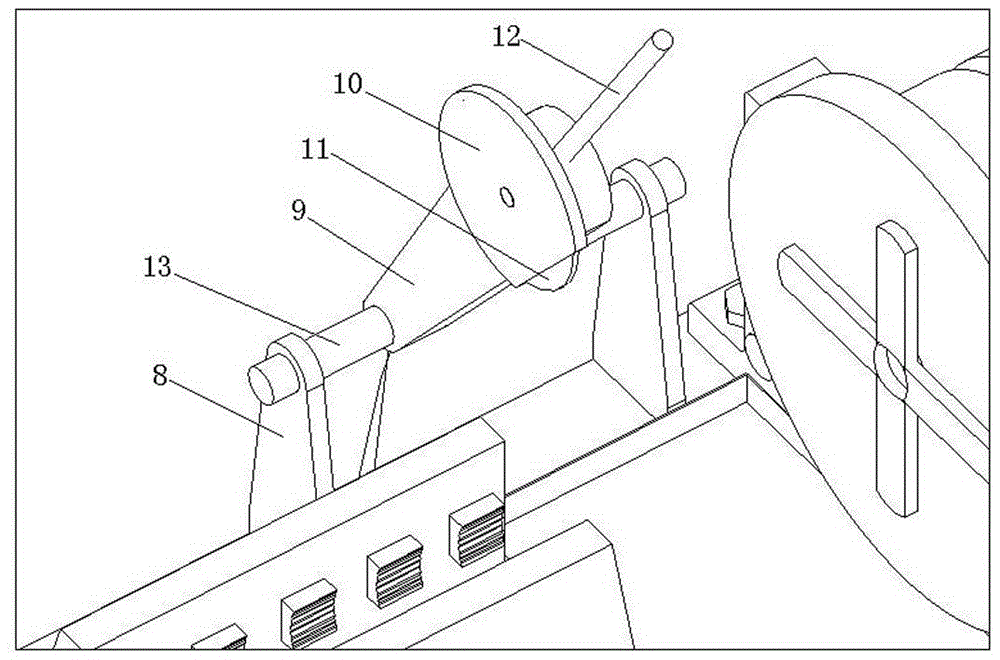

[0021] Such as Figure 1-4 As shown, the marks 1-14 in the figure respectively represent: frame 1, rolling threading machine 2, grinding device 3, clamping position 4, wheel 5, left pedal 6, right pedal 7, bracket 8, linkage 9 , Mask 10, grinding disc 11, handle 12, cross bar 13, clamping device 14.

[0022] Example: such as figure 1 and 2 As shown, the equipment for grinding and threading steel bar connection ends in this embodiment includes a frame 1, and wheels 5 are installed on the bottom of the frame 1, which is convenient for operators to move the entire equipment on the job site. The rolling and threading equipment includes a rolling and threading machine 2 and a clamping device 14 . The rolling and threading machine 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com