Simple concrete mixer

A concrete mixer and simple technology, applied in the field of mixers and simple concrete mixers, can solve problems such as affecting construction efficiency, inconvenience, single function, etc., and achieve the effects of reducing cleaning difficulty, avoiding accumulation, and comprehensive functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

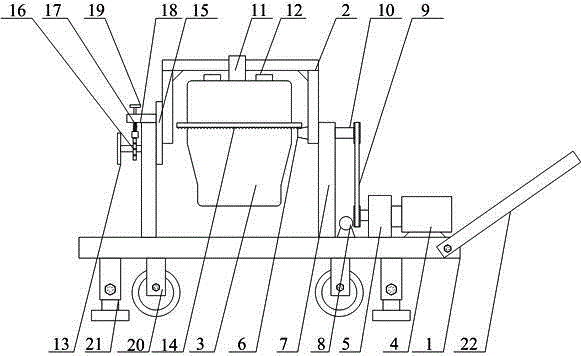

[0010] The present invention will be further described in detail below in conjunction with the drawings.

[0011] Such as figure 1 As shown, the simple concrete mixer of the present invention includes a bottom frame 1, a mixing drum 3, a door-shaped base 2, a support 7, a mixing drum rotating drive mechanism, a mixing drum turning and positioning mechanism and a water pump 8, a mixing drum 3, a door-shaped base 2, The bracket 7, the water pump 8, the mixing drum rotation driving mechanism and the mixing drum turning and positioning mechanism are arranged above the bottom frame 1. Wheels 20 and support rods 21 are installed below the underframe 1, the height of the support rod 21 can be adjusted, and the front side of the underframe is hinged with a towing link 22. The water pump 8 is connected to a power source for supplying water to the mixing drum 3.

[0012] The mixing drum 3 is arranged in the gate-shaped base 2, the bottom of the mixing drum 3 is connected with the gate-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com