A vector propulsion device, an airship and an installation method of the vector propulsion device

A technology of vector propulsion and installation method, which is applied in the direction of rigid spaceships, etc. It can solve the problems of increasing the size of the pod, rolling, and the weight of the pod structure, etc., and achieves the effects of convenient lashing operation, high lashing quality, and large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

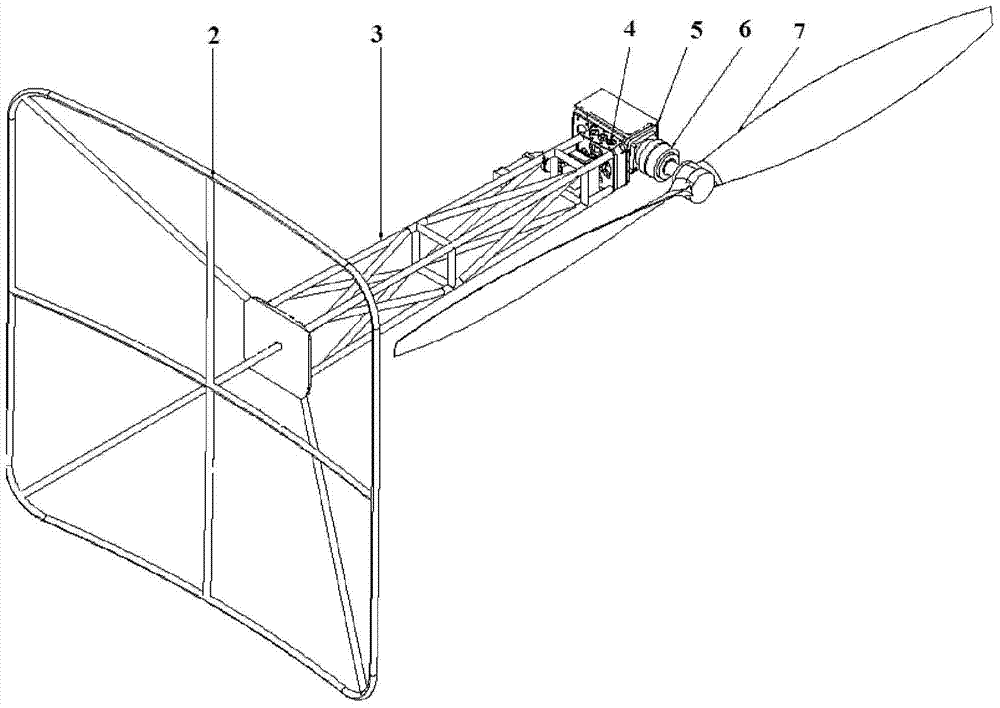

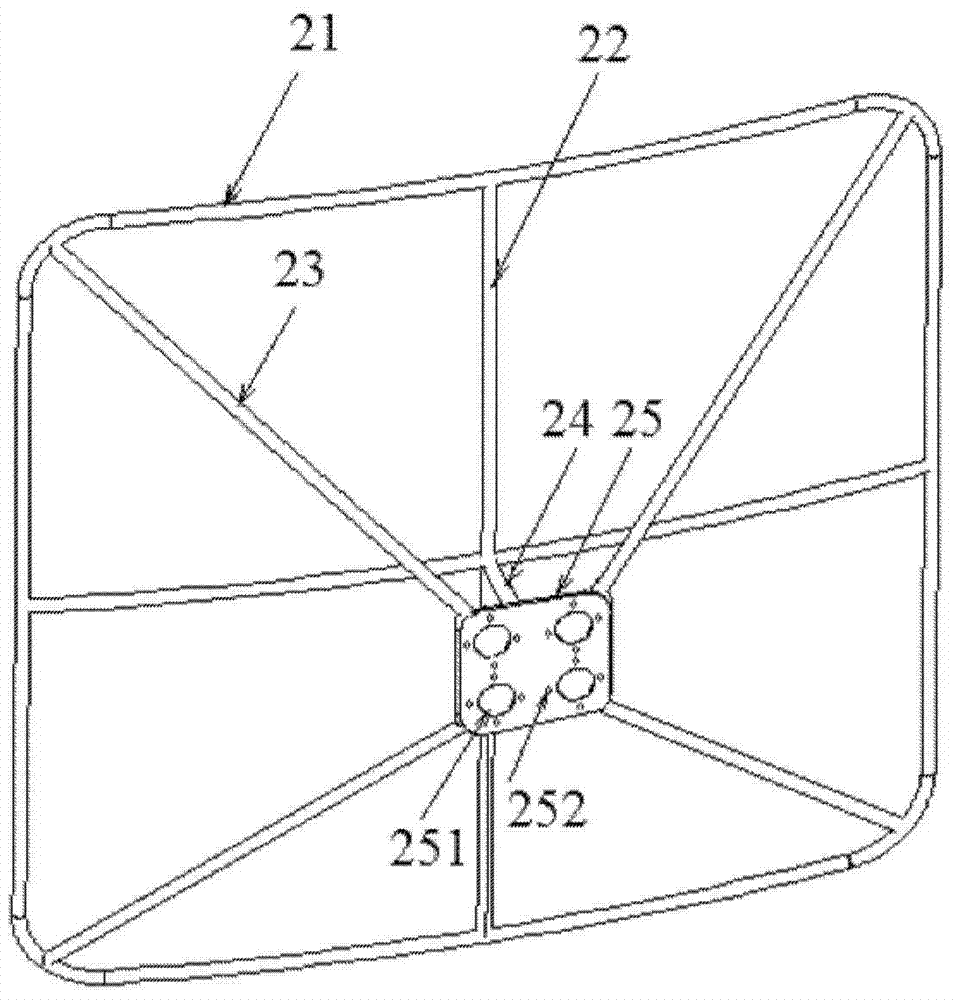

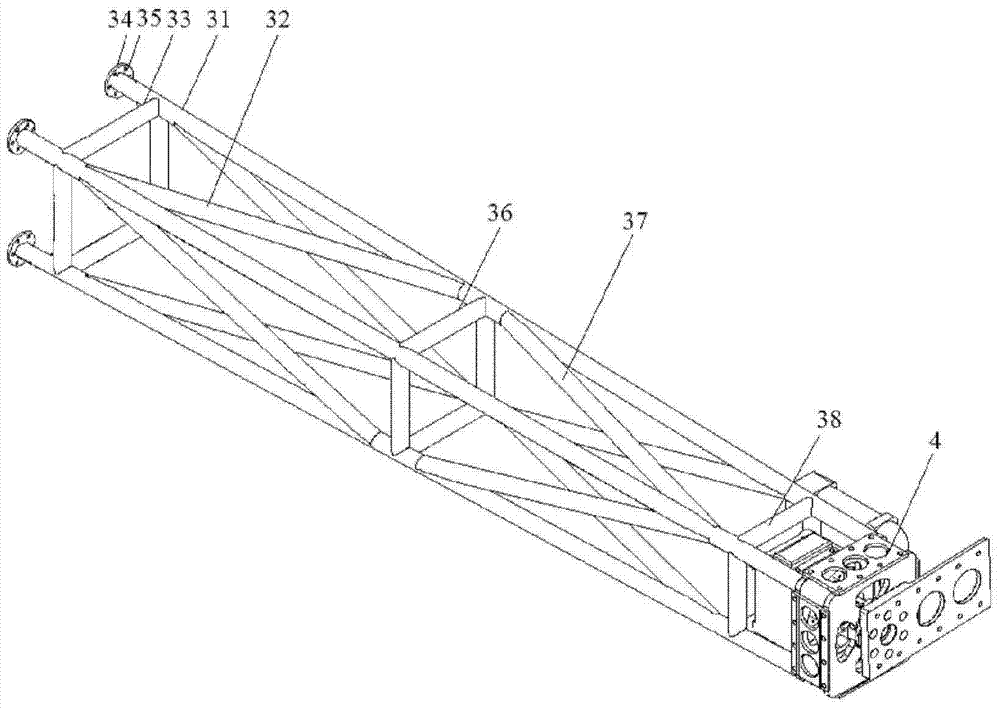

[0044] like Figure 1 to Figure 3 As shown, the vector propulsion device of this embodiment includes a driving device, the driving device in this embodiment is a power motor 5, the driving device is connected with a propeller 7, the driving device is connected with a transition frame 2, and the curvature at the bottom of the transition frame 2 is the same as that of the hull The curvature of the side part is used to install the transition frame 2. Specifically, after the hull is inflated, the overall shape is roughly ellipsoidal. The curvature of the bottom of the transition frame 2 in this embodiment is used to install the transition frame on the side of the hull. The curvatures of the 2 parts are compatible, that is, in this embodiment, the bottom of the transition frame 2 is set as a roughly concave arc-shaped matching surface that matches the side of the hull,

[0045] Specifically, the bottom of the transition frame 2 in this embodiment is a "Tian"-shaped frame, the frame...

Embodiment 2

[0063] like Figure 1 to Figure 5 As shown, this embodiment includes a kind of airship, including a hull. The hull is ellipsoidal after being inflated. Both sides of the hull are respectively provided with a vector propulsion device. The structure of the vector propulsion device in this embodiment is as in Embodiment 1. , the connection between the hull and the vector propulsion device is located at the largest diameter on both sides of the hull. By setting the vector propulsion device at the largest diameter on both sides of the hull, the size and concentrated weight of the pod can be significantly reduced, and the impact of thrust changes on the hull can be reduced. The influence of the pitch angle, and through the difference in the speed of the power motors on both sides, a greater yaw moment is obtained, thereby improving the maneuverability of the airship.

Embodiment 3

[0065] The vector propulsion device of the present invention is installed on both sides of the airship hull, and is tied to the specified position at the maximum diameter of both sides of the hull 1 through the mirror image of the transition frame 22. In order to clearly express the embodiment of the present invention, only two sets of vector The implementation of the propulsion device is described as an example. The implementation of more than 2 sets of vector propulsion devices is exactly the same as the implementation of 2 sets of vector propulsion devices. It is only necessary to increase the number of vector propulsion devices. When describing the assembly process of the vector propulsion device, one set of vector propulsion device is selected for illustration, and the assembly steps of each set are the same.

[0066] see figure 1 The structure of the vector propulsion device of the present invention is shown, including: a transition frame 2 , a propulsion bracket 3 , a t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap